Picking end effector for reducing damage to plants and fruits

A technology for end effectors and fruits, which is applied in the direction of picking machines, agricultural machinery and implements, chucks, etc., and can solve problems such as damage, irreparable target fruit, and inability to reduce small synchronous pulleys and synchronous belt stems and leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

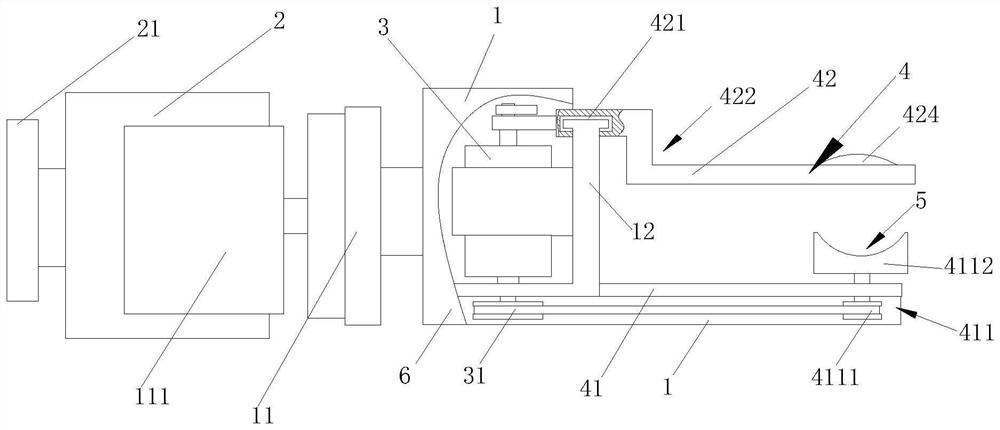

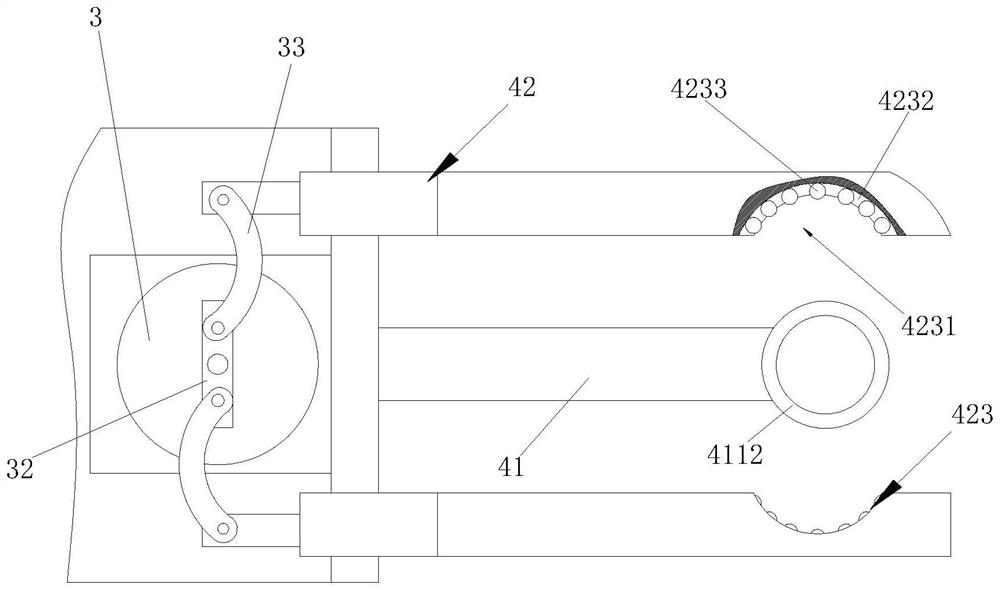

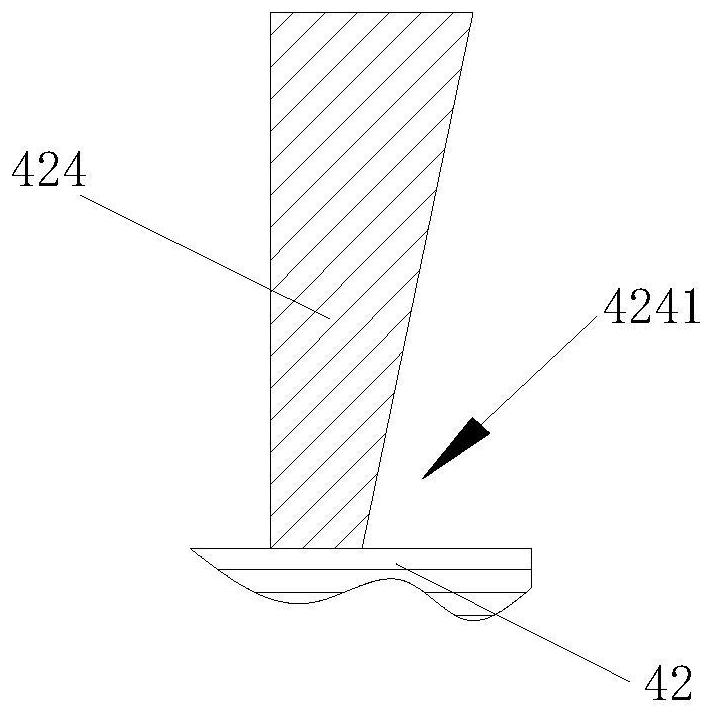

[0020] Such as figure 1 , figure 2 , image 3 with Figure 4As shown, the picking end effector for reducing plant and fruit damage includes a base 1 and a motor base 2, the motor base 2 is located at the left end of the base 1, and also includes a double output motor 3 and a clamping device 4 , the double-output motor 3 is installed in the base 1 through a connecting sleeve, the output shaft of the double-output motor 3 is vertically arranged, the clamping device 4 is located at the right end of the base 1, and the lower end of the double-output motor 3 is The output shaft of the output shaft is equipped with a large synchronous pulley 31, the clamping device 4 includes a lower jaw 41 and an upper jaw 42, the right end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com