Wave rotor and rotary thermal separator

A heat separator and wave rotor technology, applied in refrigerators, compressors, lighting and heating equipment, etc., can solve the problems of low system efficiency, reduce energy dissipation, improve cold and heat separation efficiency, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

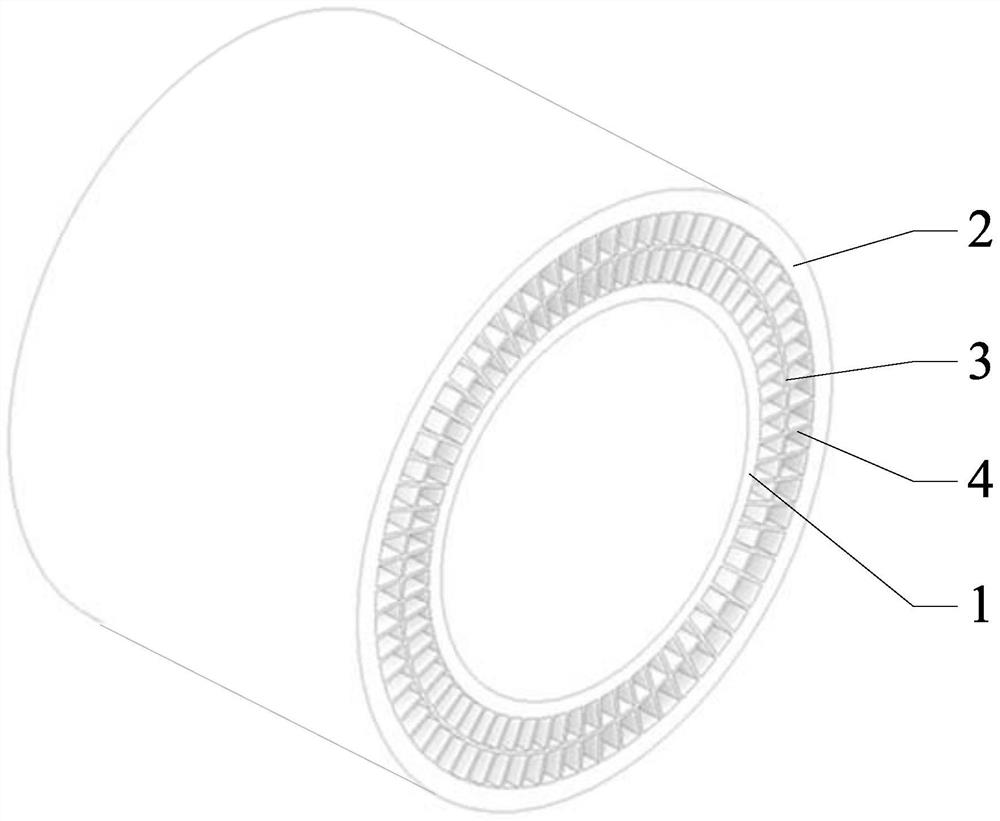

[0040] Example 1: figure 1 A schematic structural diagram of the wave rotor of this embodiment is shown. refer to figure 1 , the wave rotor in this embodiment includes a rotor inner cylinder 1 and a rotor outer cylinder 2, both of which are open-ended at both ends, and the rotor inner cylinder 1 and the rotor outer cylinder 2 are coaxially fixed;

[0041] Between the rotor inner cylinder 1 and the rotor outer cylinder 2, two layers of annular cavities are arranged along the radial direction of the rotor inner cylinder 1;

[0042] A plurality of oscillating air passages arranged along the axial length of the annular cavity in each layer are provided in each layer of the annular cavity, and a plurality of oscillating air passages in the same layer of annular cavity are distributed along the circumferential direction of the annular cavity of the layer.

[0043] The wave rotor in this embodiment further includes a sleeve-type partition 3 , which divides the gap between the rotor...

Embodiment 2

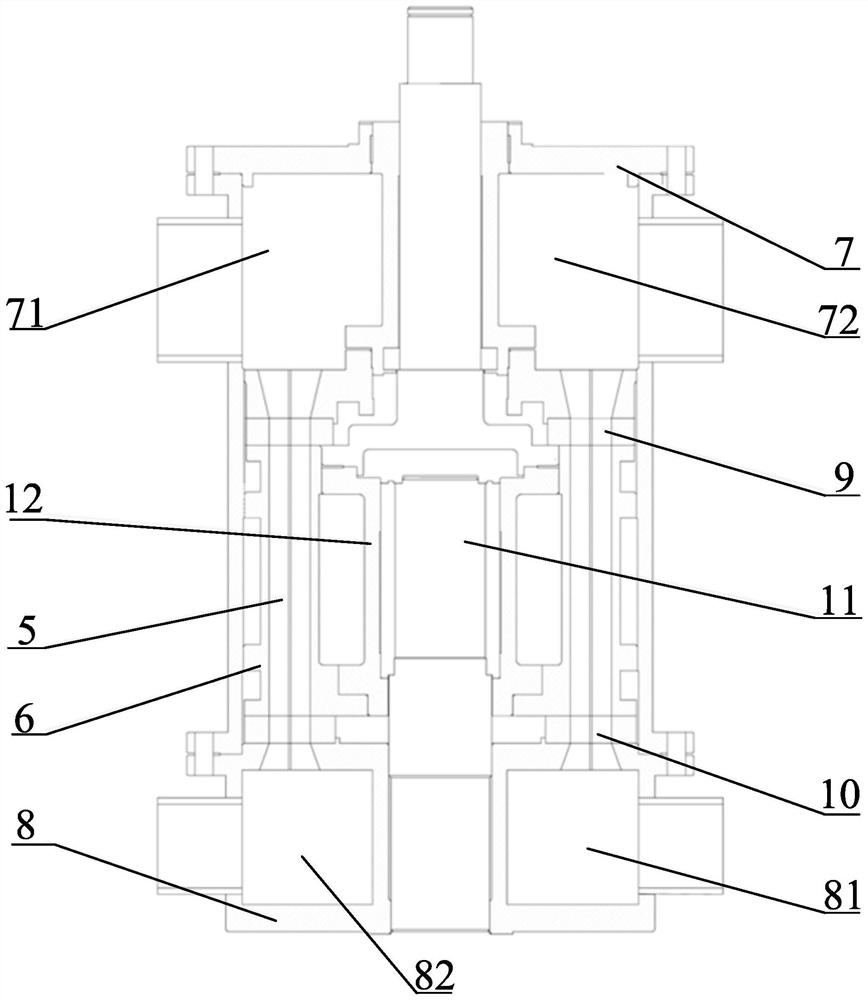

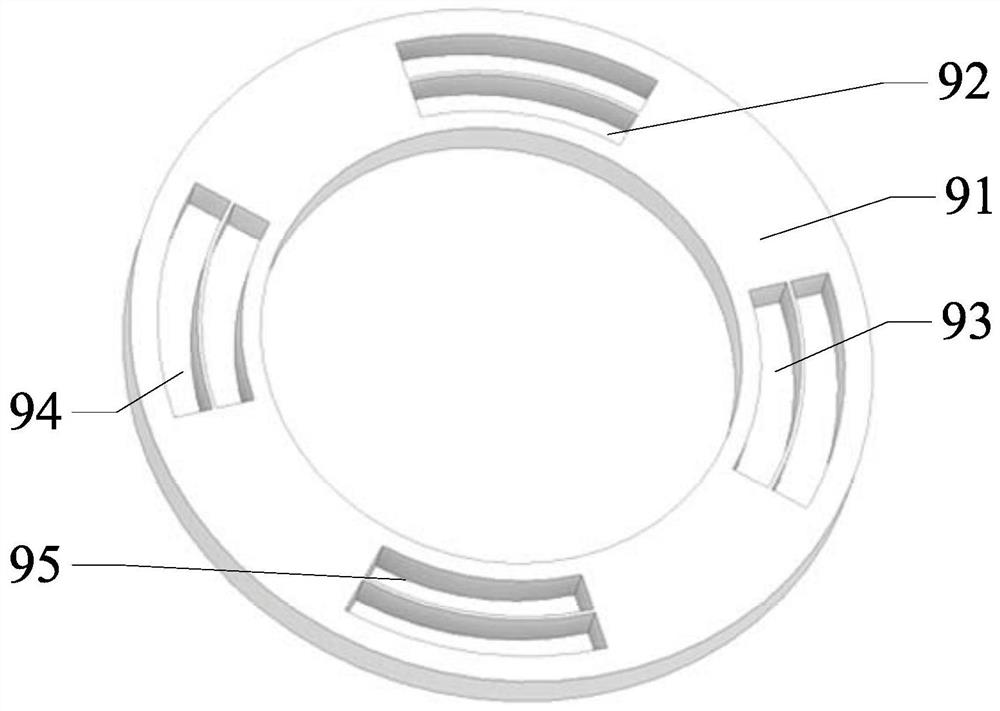

[0051] Example 2: figure 1 A schematic diagram of the structure of the wave rotor included in the rotary heat separator of the present embodiment is shown, refer to figure 1 , the wave rotor included in the rotary heat separator of this embodiment includes a rotor inner cylinder 1 and a rotor outer cylinder 2, the rotor inner cylinder 1 and the rotor outer cylinder 2 are both open-ended cylinders, the rotor inner cylinder 1 and the rotor The outer cylinder 2 is fixed coaxially;

[0052] Two layers of annular cavities are arranged between the rotor inner cylinder 1 and the rotor outer cylinder 2 along the radial direction of the rotor inner cylinder 1;

[0053] A plurality of oscillating air passages arranged along the axial length of the annular cavity of each layer are arranged in the annular cavity of each layer, and the plurality of oscillating air passages in the annular cavity of the same layer are distributed along the circumferential direction of the annular cavity of ...

Embodiment 3

[0074] Example 3: figure 1 A schematic diagram of the structure of the wave rotor included in the rotary heat separator of the present embodiment is shown, refer to figure 1 , the wave rotor included in the rotary heat separator of this embodiment includes a rotor inner cylinder 1 and a rotor outer cylinder 2, the rotor inner cylinder 1 and the rotor outer cylinder 2 are both open-ended cylinders, the rotor inner cylinder 1 and the rotor The outer cylinder 2 is fixed coaxially;

[0075] Two layers of annular cavities are arranged between the rotor inner cylinder 1 and the rotor outer cylinder 2 along the radial direction of the rotor inner cylinder 1;

[0076] A plurality of oscillating air passages arranged along the axial length of the annular cavity of each layer are arranged in the annular cavity of each layer, and the plurality of oscillating air passages in the annular cavity of the same layer are distributed along the circumferential direction of the annular cavity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com