Return air precooling heat transfer system of large air conditioning refrigerator

An air-conditioning refrigeration, pre-cooling and exchanging technology, applied in the field of heat exchange, can solve the problems of low heat exchange efficiency, large volume, and large power consumption, and achieve the effect of avoiding waste, overcoming large volume, and effectively utilizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

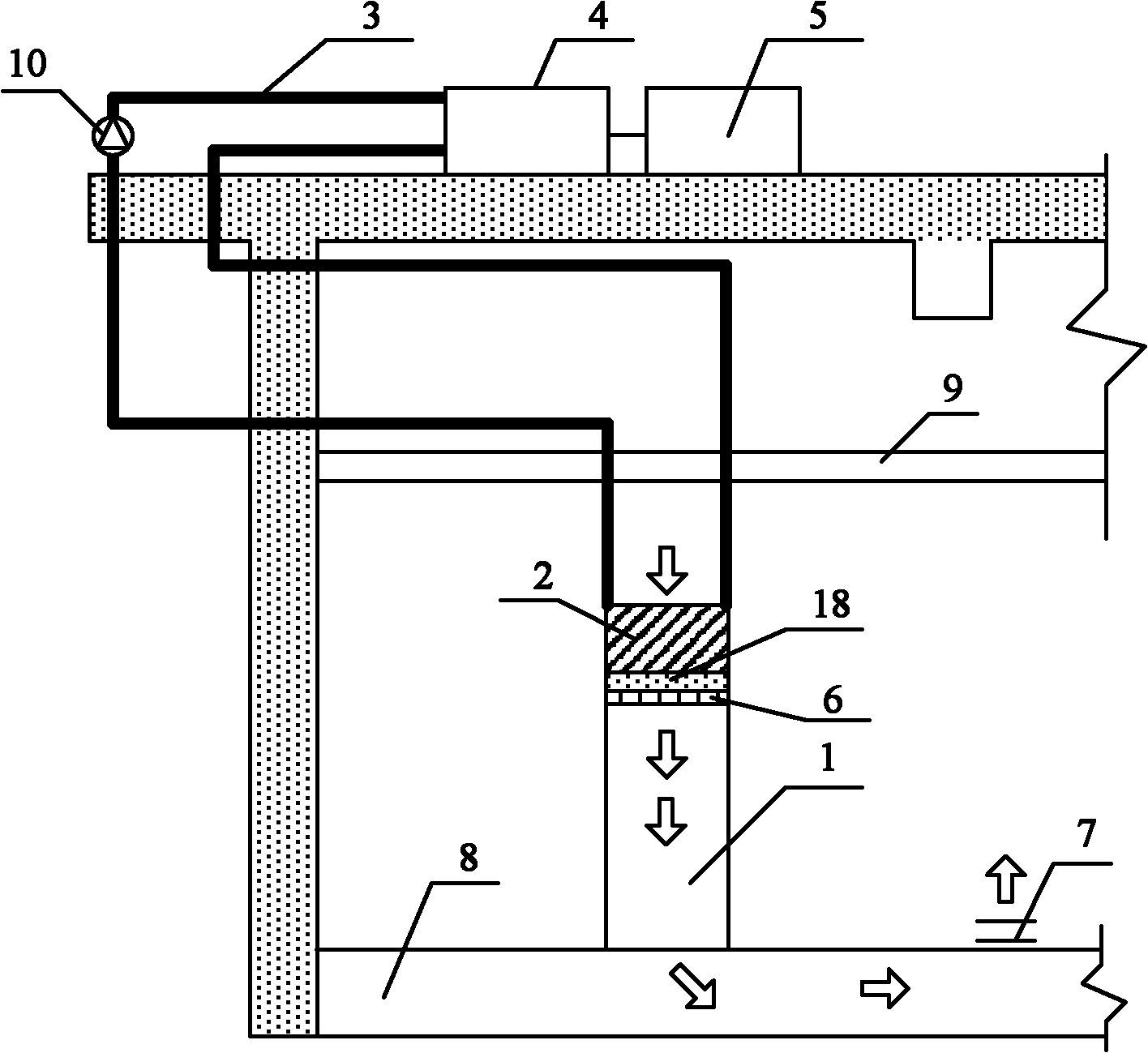

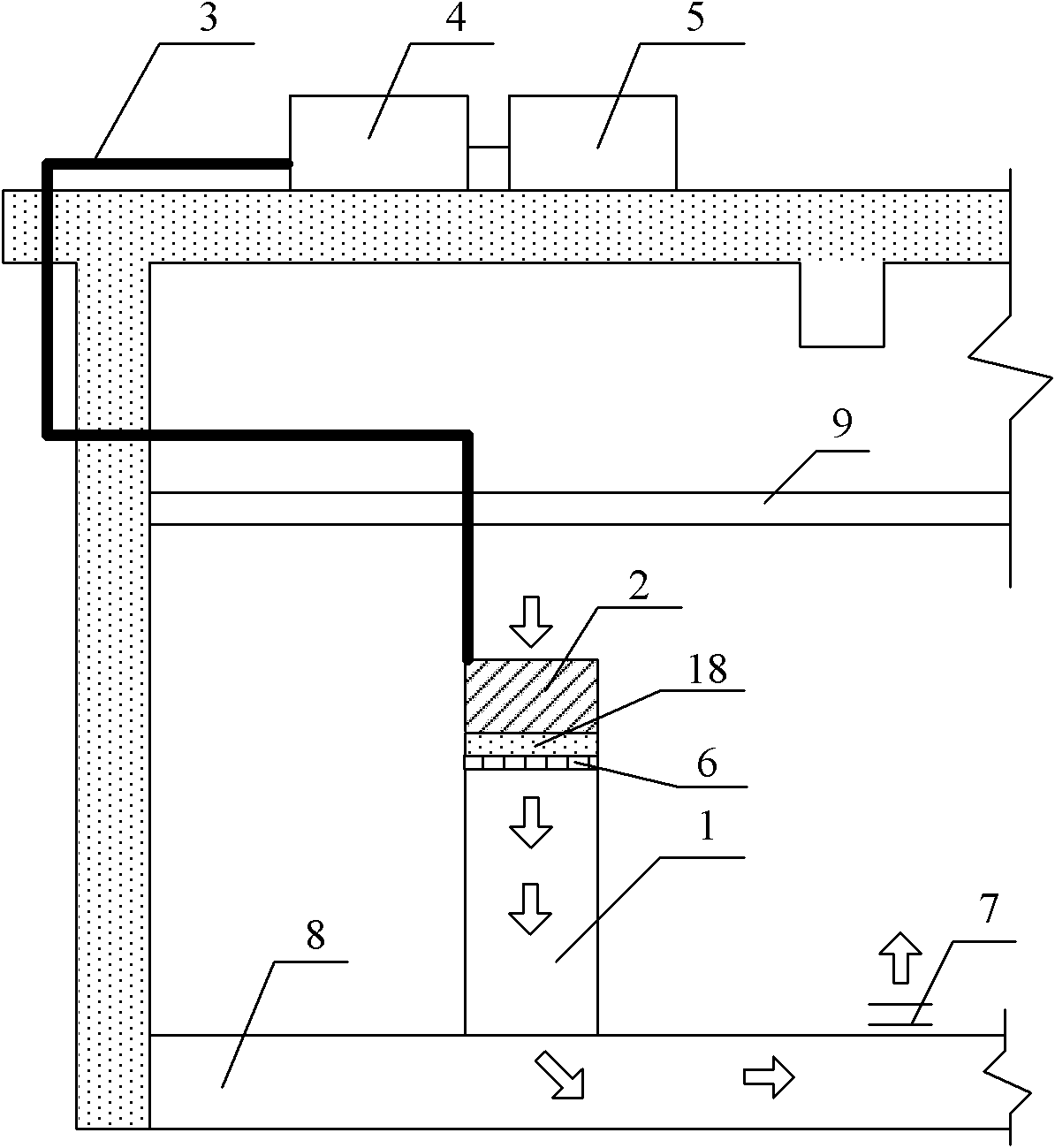

[0032] The present invention will be described below in conjunction with the accompanying drawings.

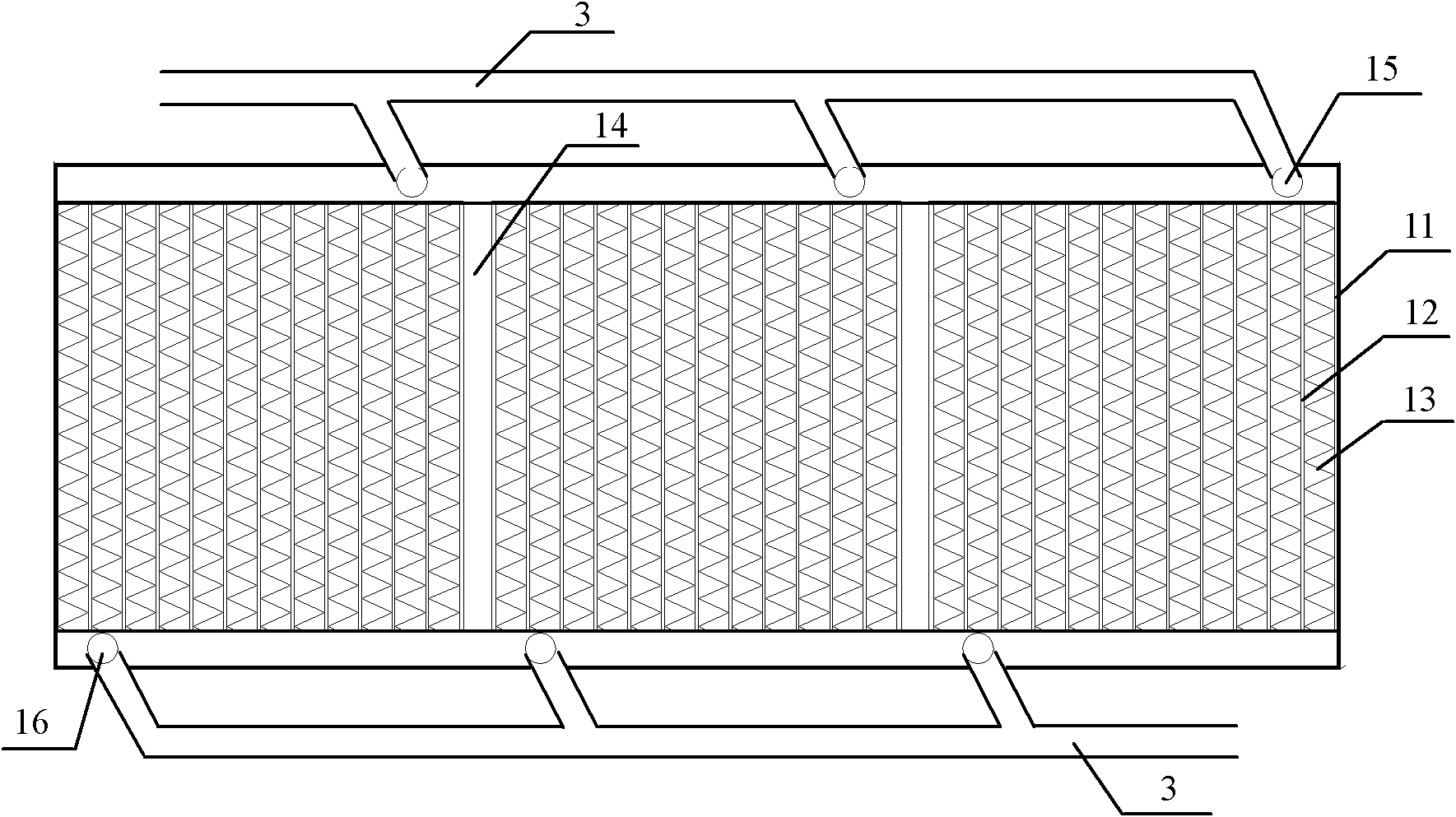

[0033] figure 1 It is a schematic diagram of the optimal structure of the return air precooling heat exchange system of a large air-conditioning refrigerator. The system includes an indoor heat exchanger 2, a fluid circuit 3, an outdoor heat exchanger 4, and an outdoor cooling device 5 connected in sequence. The indoor heat exchanger 2 It is installed at the air return port 6 of the indoor unit of the large-scale air-conditioning refrigerator 1, and the indoor heat exchanger 2 is provided with an integral air outlet 18 facing the air return port 6. The integral air outlet 18 matches the air return port 6, and the indoor heat exchanger 2 The size also matches with this return air outlet 6. The indoor heat exchanger 2 includes one or more connected metal flat tube heat exchangers, which may include single or multiple metal flat tubes and Aluminum fins connected or welded betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com