High-strength PTFE synchronous belt and preparation method thereof

A technology of PTFE and synchronous belts, which is applied in the direction of belts, transmission belts, mechanical equipment, etc., can solve the problem that PTFE coating is difficult to compound with tooth cloth layer, and achieve the effect of avoiding short board effect and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

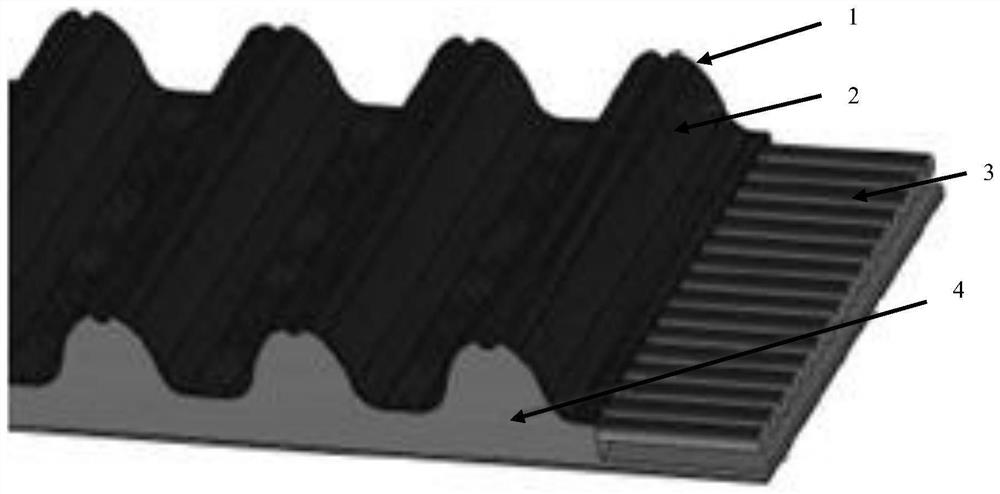

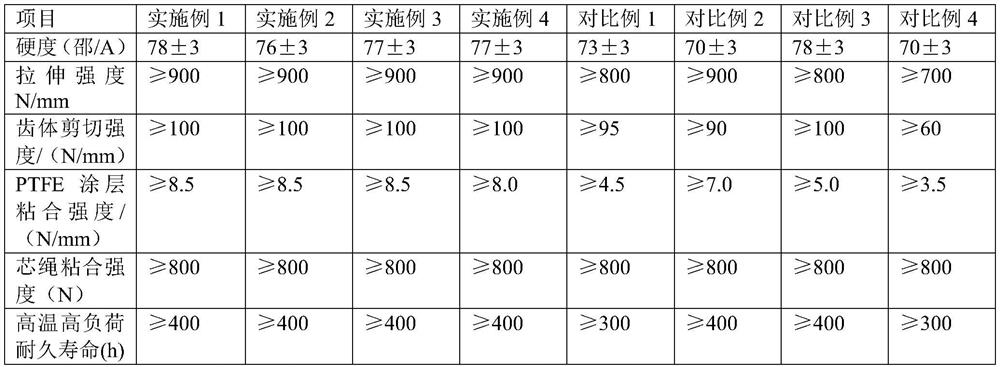

[0021] A high-strength PTFE timing belt, such as figure 1 As shown, it is composed of rubber layer 4, wire rope 3, tooth cloth layer 2 and PTFE coating 4. The material of the rubber layer 4 is HNBR containing aramid staple fibers, and the mass ratio of HNBR and aramid staple fibers is 100:4. The addition of aramid staple fibers can significantly improve the modulus of modulus and modulus of the rubber layer under small strains. . The rubber layer 4 is embedded with several wire ropes 3 arranged in parallel along the length direction. The wire ropes 3 are HNBR glass fiber wire ropes, that is, the surface of the glass fiber is impregnated with HNBR latex to improve the fatigue resistance of the wire ropes. One side surface of the rubber layer 4 is in the shape of a continuous tooth, and the surface is provided with a tooth cloth layer 2, and the tooth layer 2 is made of nylon elastic cloth. The surface of tooth cloth layer 2 is coated with modified PTFE coating 1, and the prep...

Embodiment 2

[0026] The difference with Example 1 is that the mass ratio of HNBR and aramid staple fiber in the rubber layer 4 is 100:1; in the preparation method of modified PTFE coating 1, surface-modified PTFE and ZDMA are by mass ratio 100:5 Mixing, surface-coated PTFE and HNBR are mixed at a mass ratio of 1.6:1.

Embodiment 3

[0028] The difference with Example 1 is that the mass ratio of HNBR and aramid staple fiber in the rubber layer 4 is 100:5; in the preparation method of modified PTFE coating 1, surface-modified PTFE and ZDMA are by mass ratio 100:20 Mixing, surface-coated PTFE and HNBR are mixed at a mass ratio of 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com