Novel in-screen punching and touch integrated module

A new type of integrated technology, applied in the field of display screens, can solve the problems of reduced lamp bead life, poor heat dissipation, and light intensity changes, and achieve the effects of reducing light intensity changes, improving stable connectivity, and reducing distance changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

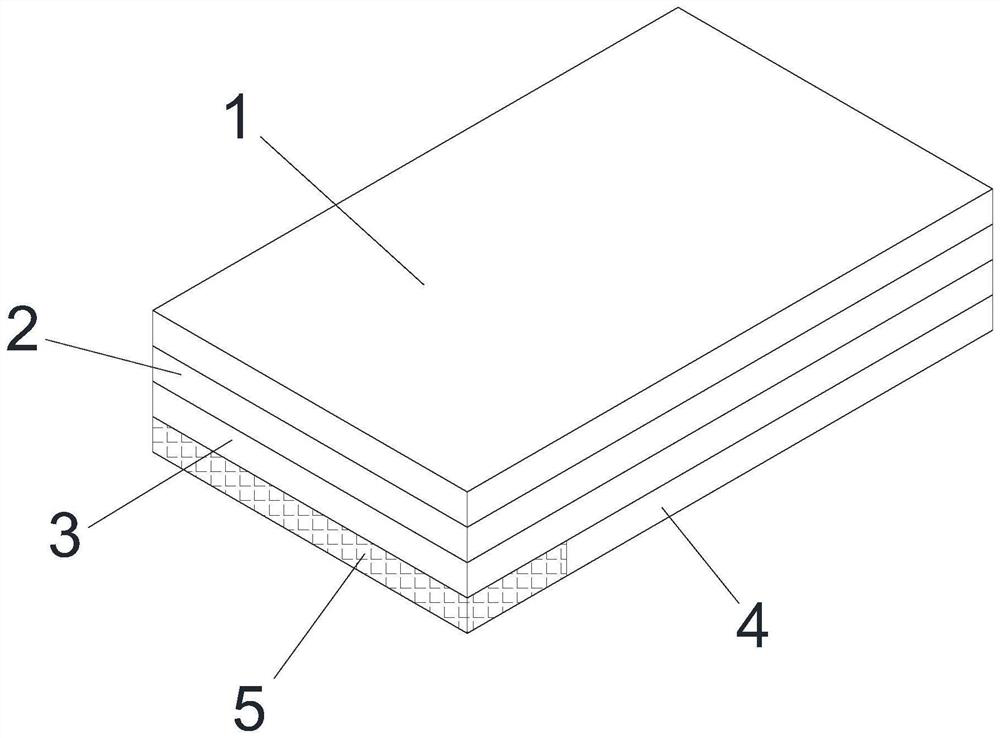

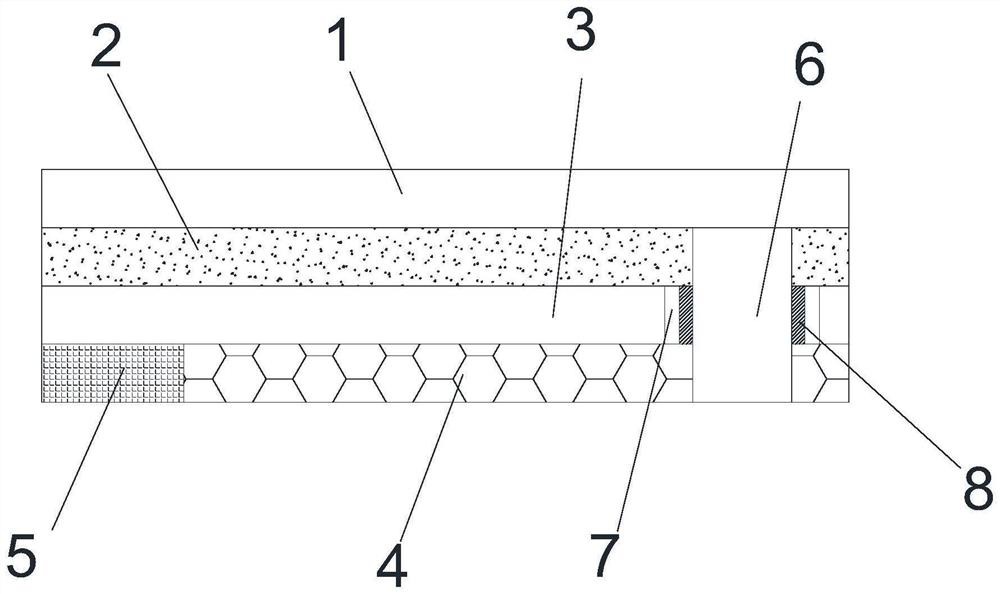

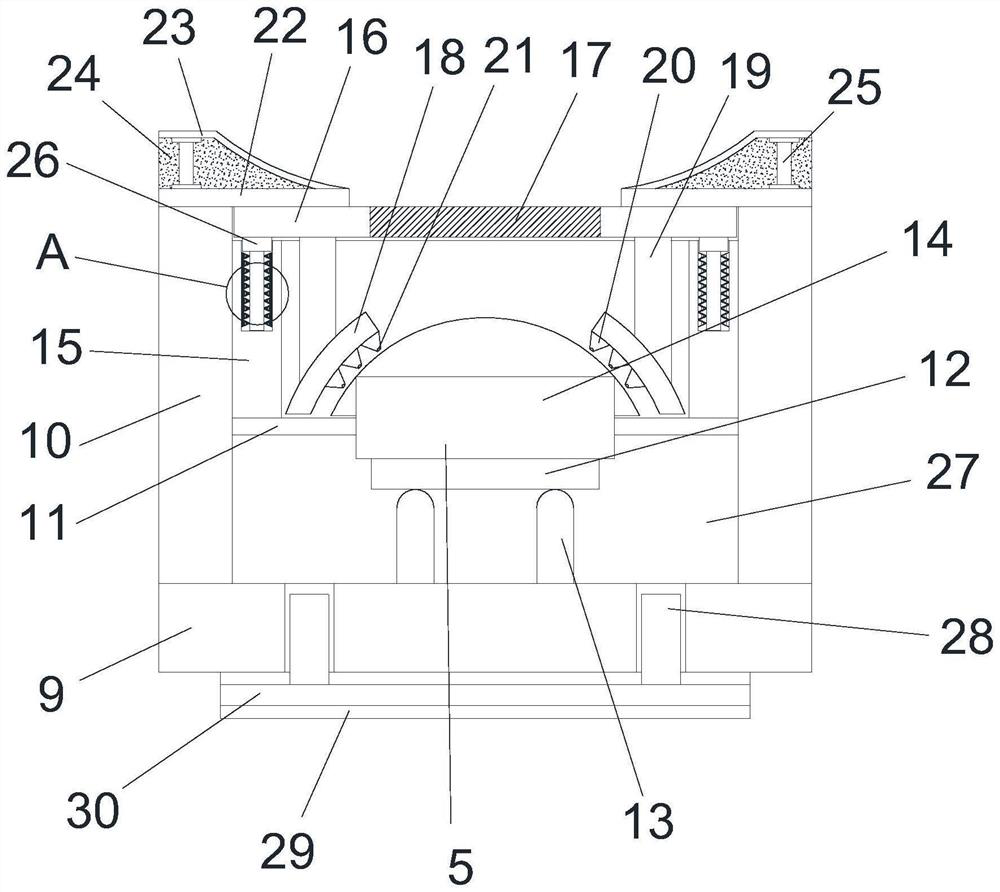

[0025] Embodiment: A new type of perforated and touch integrated module in the screen, such as Figure 1-Figure 4 As shown, it includes a glass cover plate 1, an LCD display 2 is fixedly installed at the bottom of the glass cover plate 1, a light guide plate 3 capable of guiding light is fixedly installed at the bottom of the LCD display screen 2, and a backlight plate is fixedly installed at the bottom of the light guide plate 3 4. The left end of the backlight panel 4 is provided with an LED lamp group 5, and the right end of the bottom wall of the backlight panel 4 is provided with a screen hole 6, and the screen hole 6 runs through the corresponding wall surface of the LCD display screen 2 and the light guide plate 3 and extends to the glass cover 1, the inner side of the light guide plate 3 is provided with a reflector 8 corresponding to the position of the inner hole 6 of the screen, and the outer end of the reflector 8 is provided with a diffuser 7;

[0026] The LED lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com