A marine impeller maintenance system

A technology for maintaining systems and impellers, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, pump components, etc., which can solve the inconvenience of impeller installation and removal, rotor vibration damage, impeller balance damage, etc. problems, to achieve the effect of improving detection accuracy, improving accuracy, and reducing shaking and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

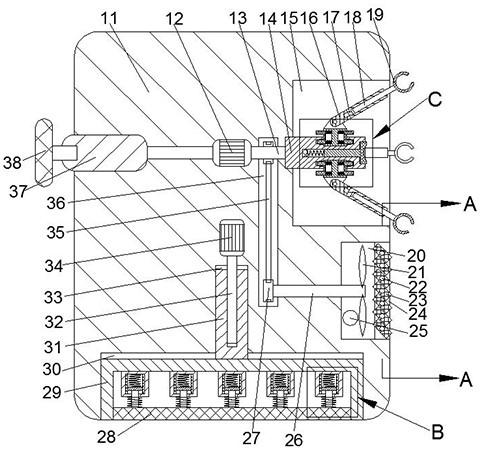

[0027] In order to make the objects and advantages of the present invention more clearly, the present invention will be specifically described below, and it is understood that the following text is only used to describe a marine impeller maintenance system or several specific embodiments of the present invention. The protection range of the specific request of the present invention is strictly limited. If used herein, the terms upper and down and left and right are not limited to its strict geometric definition, but includes a tolerance for the reasonable and inconsistency of the machining or human error, the following detailed description The specific characteristics of the marine impeller maintenance system:

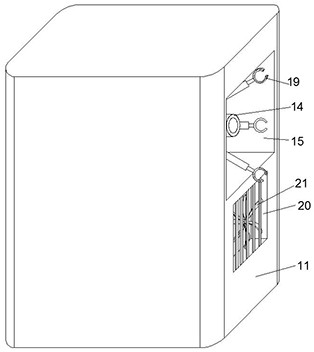

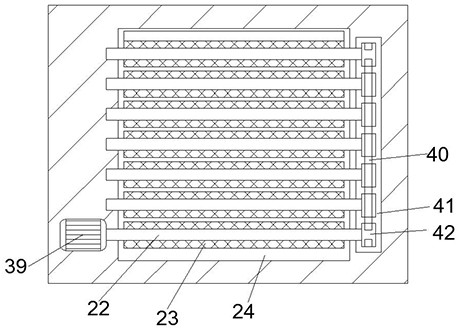

[0028] Refer Figure 1-8, A marine impeller maintenance system, including an impeller maintenance body 11, and an impeller maintenance body 11, and the left wall of the working chamber 15 is rotated with a workpiece. 14. The working panel 14 is rotated in the center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com