Oxygen-enriched direct-current combustor with adjustable combustion performance

A combustion performance and burner technology, which is applied in the direction of burners, burners, and combustion methods for burning powder fuels, can solve problems such as insufficient combustion, poor fire stability, etc., to alleviate slagging and high-temperature corrosion, and increase oxygen concentration , The effect of reducing the amount of engineering transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings. Obviously, it should be understood here that the described embodiments are not all embodiments, and are only used to illustrate the present invention, not to limit the present invention.

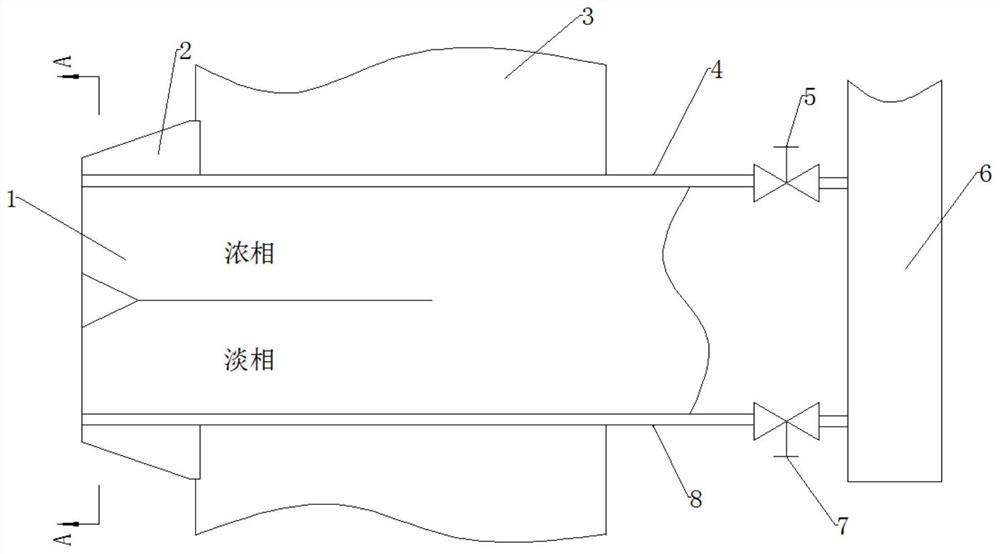

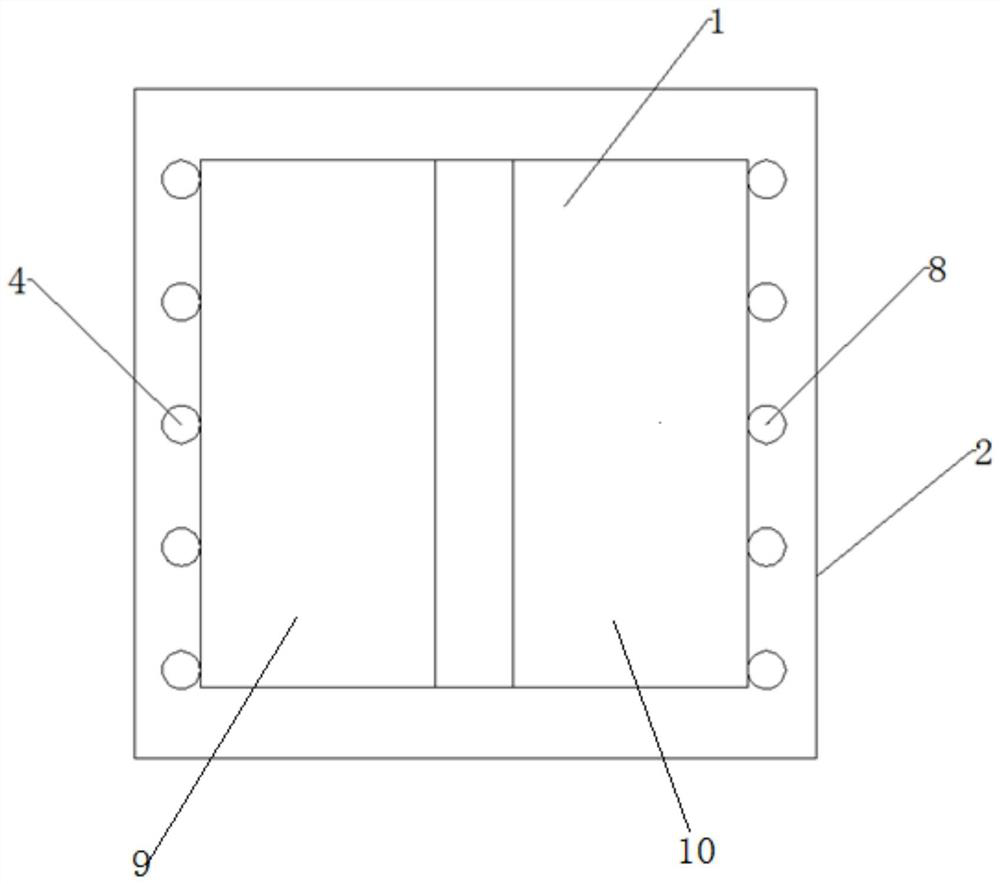

[0021] The present invention provides an oxygen-enriched direct-flow burner with adjustable combustion performance. The oxygen-enriched direct-flow burner includes a thick-lean direct-flow burner 1, a perimeter air chamber 2, a dense-phase oxygen injection pipe gun 4, and a light-phase oxygen injection pipe gun 7; The dense-phase oxygen injection pipe gun 4 and the light-phase oxygen injection pipe gun 7 are evenly distributed in the perimeter air chamber 2 on the dark side; the pipeline of the dense-phase oxygen injection pipe gun 4 is provided with a dense-phase oxygen injection regulating valve group 5; The pipeline of the oxygen injection pipe gun 7 is provided with a ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com