Intelligent defect detection equipment for packaged chip

A technology of intelligent detection and defect detection, applied in sorting and other directions, which can solve problems such as pin deformation, lack of chip pin detection, and unfavorable installation processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

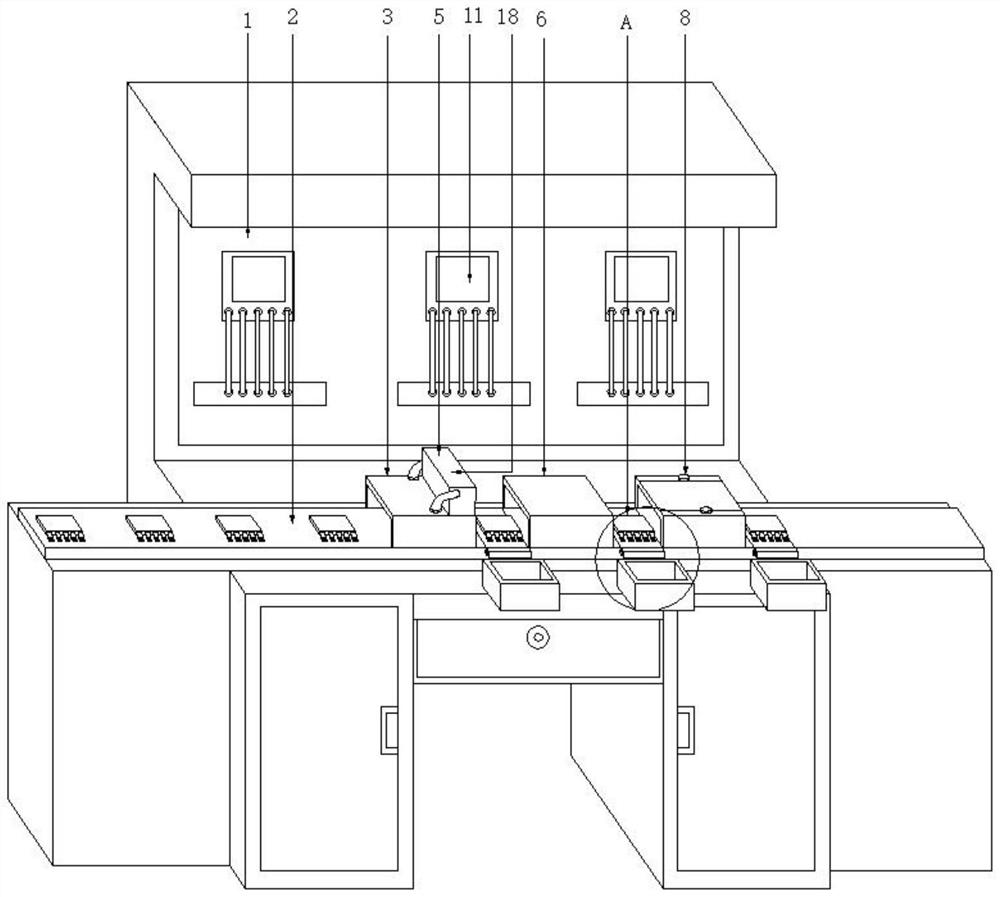

[0024] Example 1: See Figure 1-6 , the present invention provides a technical solution: a defect intelligent detection device for packaged chips, including a chip lead defect detection device, the chip lead defect detection device mainly includes an operation table 1, a conveyor 2, a lead shape detector, a lead Foot electrification detector, appearance image detector and rejecting mechanism, conveyor 2 is installed on console 1, pin shape detector is installed on console 1 and directly above conveyor 2, pin shape detector It is composed of a body casing 3, a lead corner detector 4 and a sprayer 5. The lead corner detector 4 is divided into two groups and is symmetrically installed inside the body casing 3. The sprayer 5 is located on the back of the body casing 3. The pin electrification detector is installed on the right side of the pin shape detector and includes two sets of circuit detection splints 7 slidingly arranged on the inner wall of the body shell II 6, and the app...

Embodiment 2

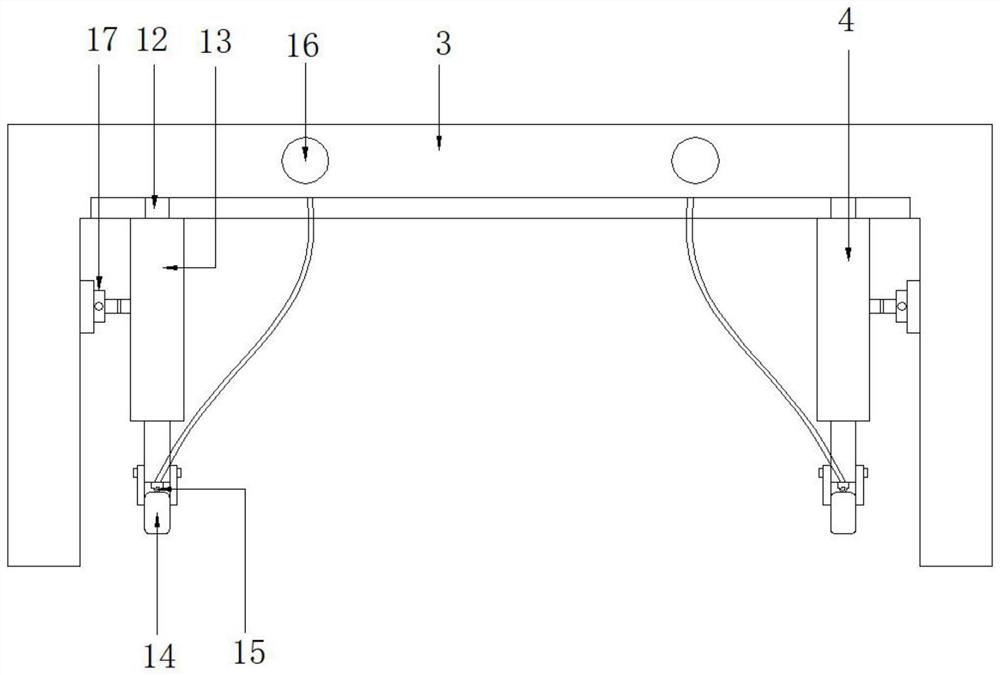

[0025] Embodiment 2: as figure 2 As shown: the pin corner detector 4 is composed of a slider 12, a telescopic rod 13, a corner detection wheel 14, a pressure sensor 15, an indicator light 16 and an electric push rod-17, and the slider 12 is slidably arranged on the inner wall of the body shell-3 The upper and lower ends are fixedly connected with the telescopic rod 13. The telescopic rod 13 has a two-stage structure and the corner detection wheel 14 is installed at the lower end. Connected, the indicator light 16 is installed on the front side of the body shell-3, the electric push rod-17 is installed on the side wall of the body shell-3 and the power output end is connected with the telescopic rod 13, and the electric push rod-17 promotes the telescopic rod 13 to move and make the corner detection wheel 14 corresponding to and in contact with the corner position of the pin, the pressure sensor 15 detects the pressure of the corner detection wheel 14, when the pressure value ...

Embodiment 3

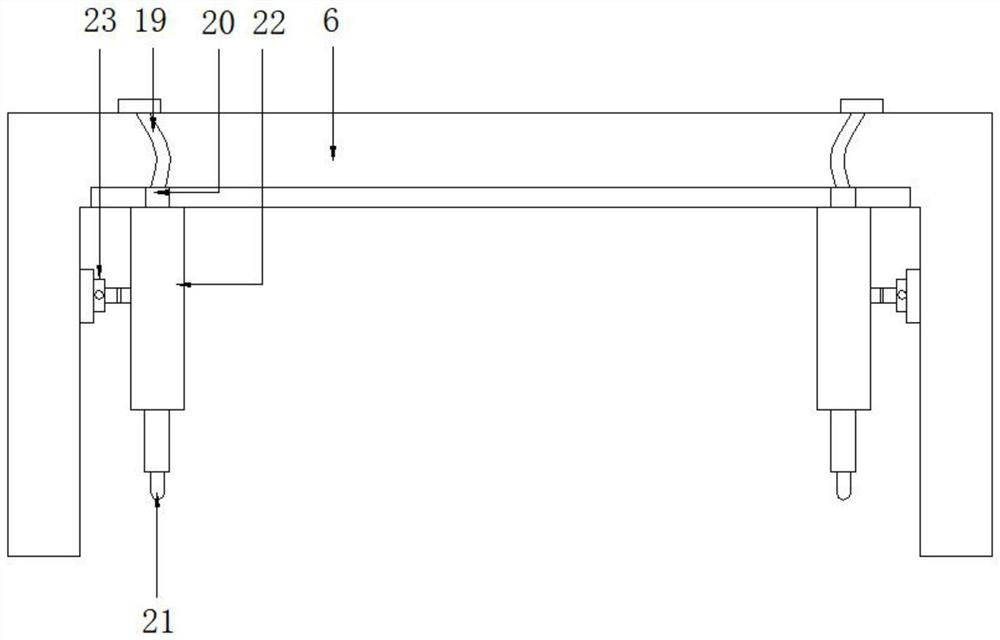

[0027] Embodiment 3: as image 3Shown: the sprayer 5 comprises the accommodation box 18 that is installed on the body shell one 3 and two groups of infusion tubes 19 that are connected with the accommodation box 18 through pipelines, the lower ends of the two groups of infusion tubes 19 are equipped with pumps 20, and the pumps 20 pass through The infusion tube 19 is connected with a spray head 21, the upper end of the spray head 21 is equipped with a vertical rod 22, the vertical rod 22 is slidably arranged on the inner wall of the body shell one 3 and one side is connected with an electric push rod two 23, and the pump 20 pumps the inside of the housing box 18 The marking solution is pumped to the nozzle 21, and sprayed on the corresponding pins through the nozzle 21, so as to facilitate the corresponding processing of the subsequent pins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com