Preparation method of morinda citrifolia juice and morinda citrifolia juice

A technology of noni fruit and noni pulp, applied in the direction of freezing/cold preservation of fruits/vegetables, food science, etc., can solve problems such as dissolution, harm, and influence on taste and quality, so as to ensure food safety, prevent cracking, The effect of increasing the juice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

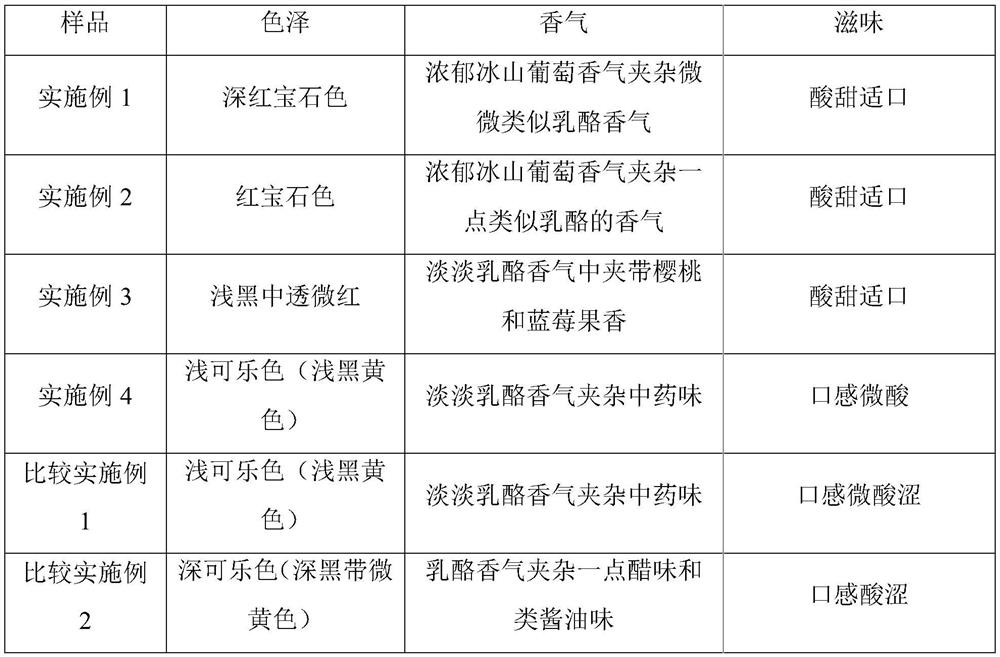

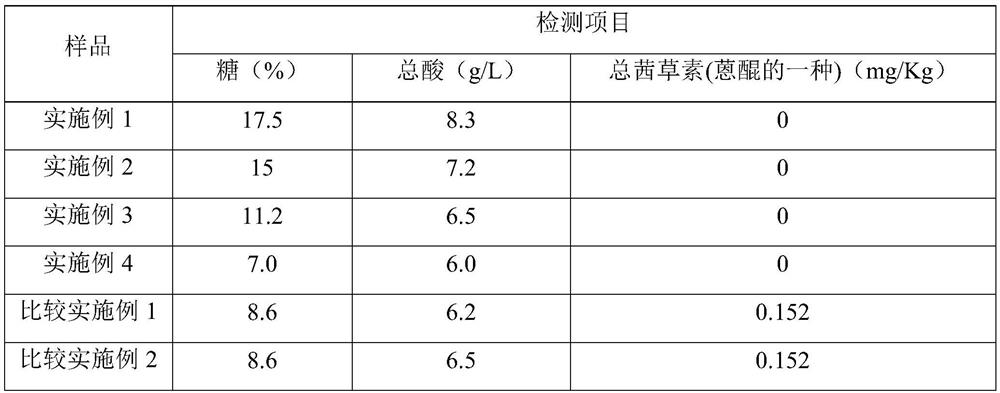

Examples

Embodiment 1

[0035] Embodiment 1: a kind of preparation method of noni fruit juice, comprises the steps:

[0036] S1. Pick the fully mature noni fruit from the tree and put it in the basket, handle it gently without breaking the peel; soak and rinse with pure water to remove the surface mud, sand and dust. Naturally control the moisture, or use a 600 rpm centrifuge to remove the moisture on the surface of the noni fruit;

[0037] S2. Adopt quick-freezing method to make the core temperature of Noni fruit reach -16°C;

[0038] S3, peeling the noni fruit after quick freezing; specifically include the following steps:

[0039] Soak the quick-frozen Noni fruit in a NaOH solution for 1 minute, the temperature of the NaOH solution is 90°C, and the concentration of the NaOH solution is 7%;

[0040] After soaking in pure water, soak in 0.05% citric acid solution for 2 minutes;

[0041] Remove the skin of the soaked Noni fruit.

[0042] S4, using a multifunctional vegetable cutter, a crusher or ...

Embodiment 2

[0049] Embodiment 2: a kind of preparation method of Noni fruit juice, comprises the steps:

[0050] S1. Pick the fully mature noni fruit from the tree and put it in the basket, handle it gently without breaking the peel; soak and rinse with pure water to remove the surface mud, sand and dust. Naturally control the moisture, or use a 700 rpm centrifuge to remove the moisture on the surface of the noni fruit;

[0051] S2, adopt quick-freezing method to make the core temperature of noni fruit reach -18 ℃;

[0052] S3, peeling the noni fruit after quick freezing; specifically include the following steps:

[0053] Soak the quick-frozen Noni fruit in a NaOH solution for 1 minute, the temperature of the NaOH solution is 92°C, and the concentration of the NaOH solution is 8%;

[0054] After soaking in pure water, soak in 0.05% citric acid solution for 1 minute;

[0055] Remove the skin of the soaked Noni fruit.

[0056] S4, using a multifunctional vegetable cutter, a crusher or m...

Embodiment 3

[0063] Embodiment 3: a kind of preparation method of Noni fruit juice, comprises the steps:

[0064] S1. Pick the fully mature noni fruit from the tree and put it in the basket, handle it gently without breaking the peel; soak and rinse with pure water to remove the surface mud, sand and dust. Naturally control the moisture, or use an 800 rpm centrifuge to remove the moisture on the surface of the noni fruit;

[0065] S2. Adopt quick-freezing method to make the core temperature of Noni fruit reach -19°C;

[0066] S3, peeling the noni fruit after quick freezing; specifically include the following steps:

[0067] Soak the quick-frozen Noni fruit in a NaOH solution for 2 minutes, the temperature of the NaOH solution is 93°C, and the concentration of the NaOH solution is 11%;

[0068] After soaking in pure water, soak in 0.05% citric acid solution for 2 minutes;

[0069] Remove the skin of the soaked Noni fruit.

[0070] S4, using a multifunctional vegetable cutter, a crusher ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com