Sinker cap device of hosiery machine

A kind of technology for making hoods and hosiery machines, which is applied in textiles and papermaking, knitting, weft knitting, etc. It can solve the problems affecting the quality of socks, smooth transition, and easy to appear lines, etc., so as to achieve smooth socks, improve quality, and controllability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the solution of the present invention, the invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

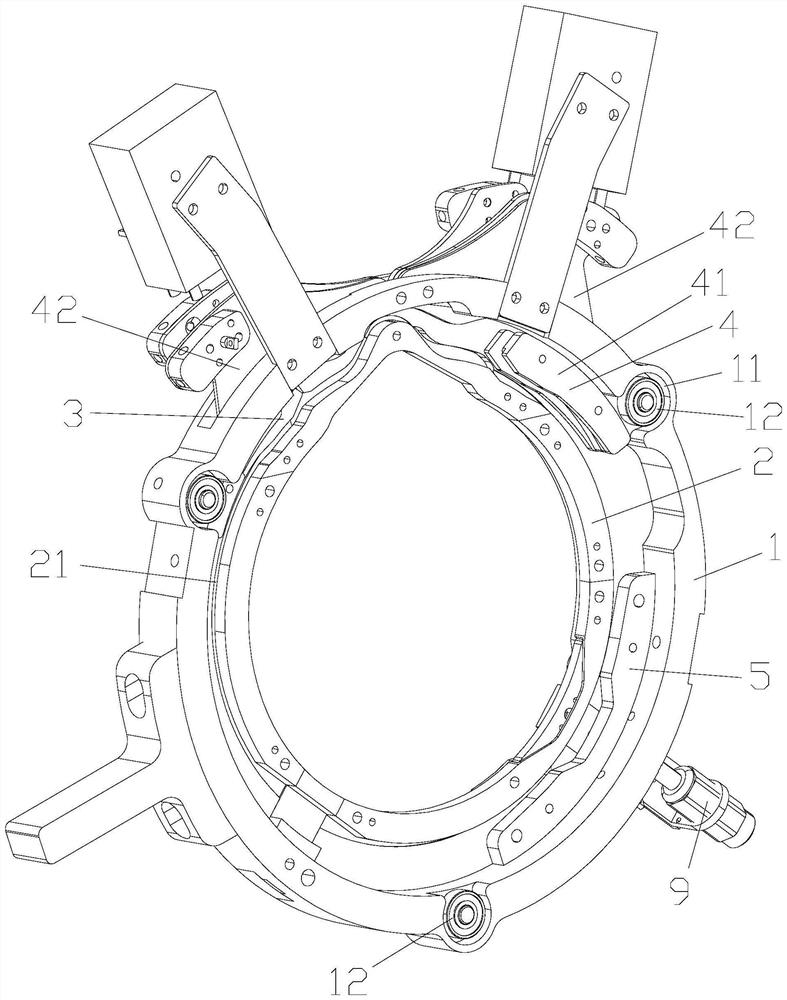

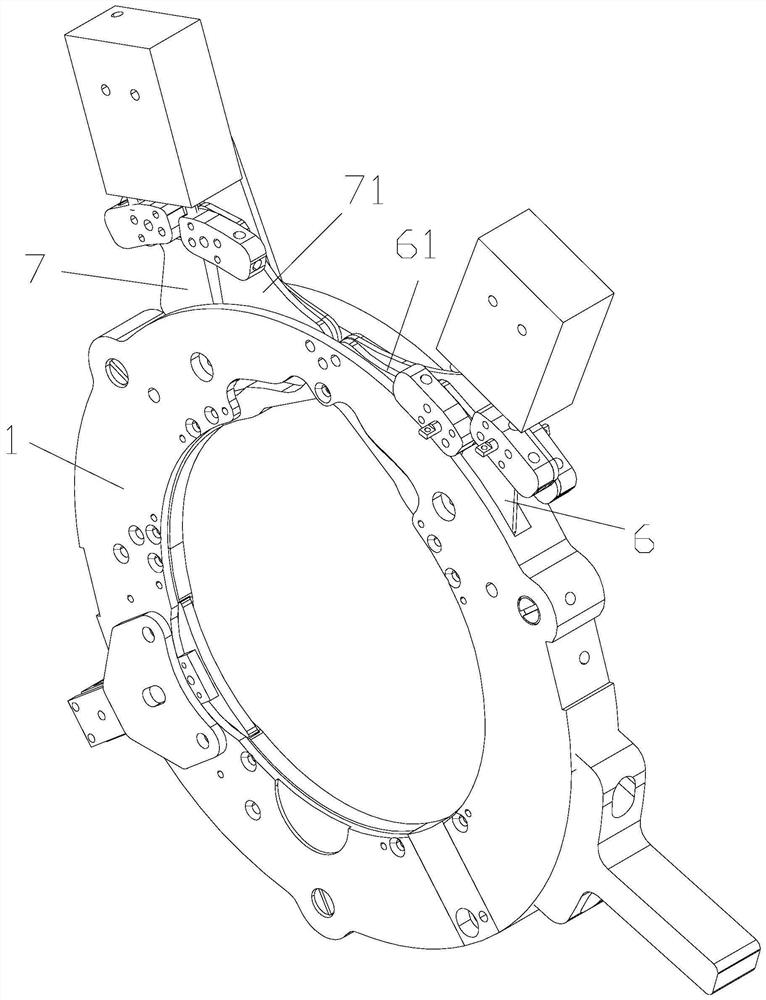

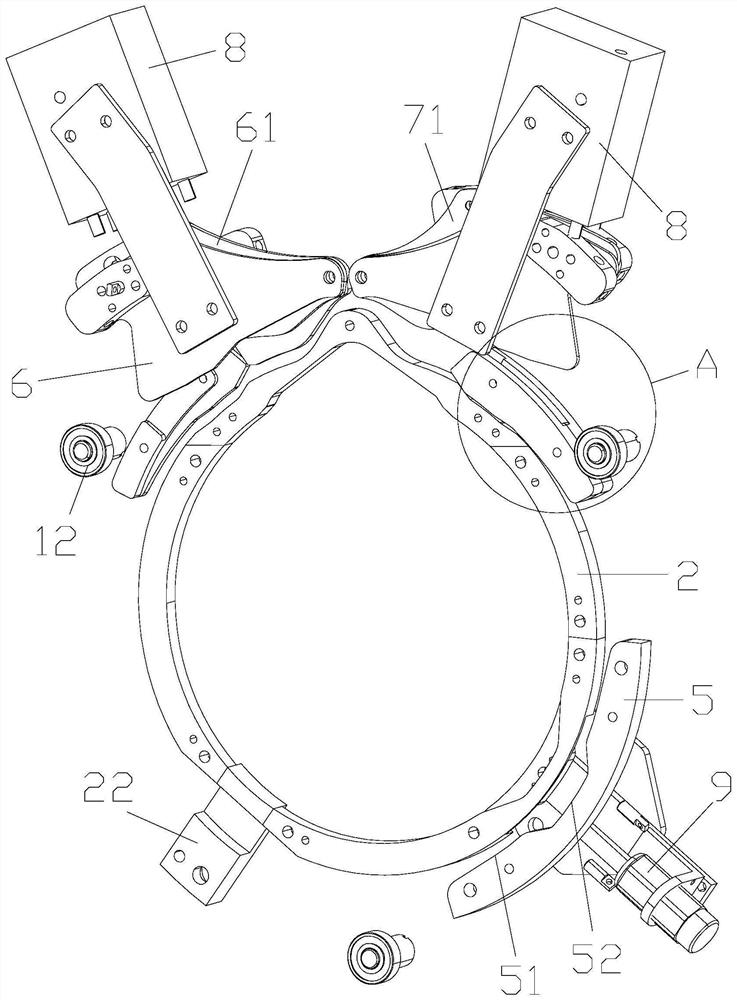

[0021] Such as Figure 1-Figure 4 The shown squeegee device of a hosiery machine includes a squeaker shell 1 and a middle eyebrow 2, a left eyebrow 3, a right eyebrow 4 and an outer eyebrow 5 arranged inside the squeaker shell 1. The eyebrows 2 and the Sinker housing 1 are arranged concentrically, and a syringe channel 21 is formed between the middle eyebrow 2 and the Sinker housing 1, and the left eyebrow 3, the right eyebrow 4 and the outer eyebrow 5 are all located in the syringe channel 21 The outer side and around the middle eyebrow 2 are set, and the syringe channel 21 is used to install the syringe. The right eyebrow 4 includes a fixed eyebrow 41 fixedly connected to the Sinker housing 1 and a movable eyebrow 42 slidably connected to the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com