Graphite cathode material crucible automatic charging system

A graphite negative electrode and automatic loading technology, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc., can solve the problems of serious dust in manual loading, high labor intensity of workers, and poor working environment of workers, so as to improve the working environment, The effect of improving production efficiency and ensuring production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

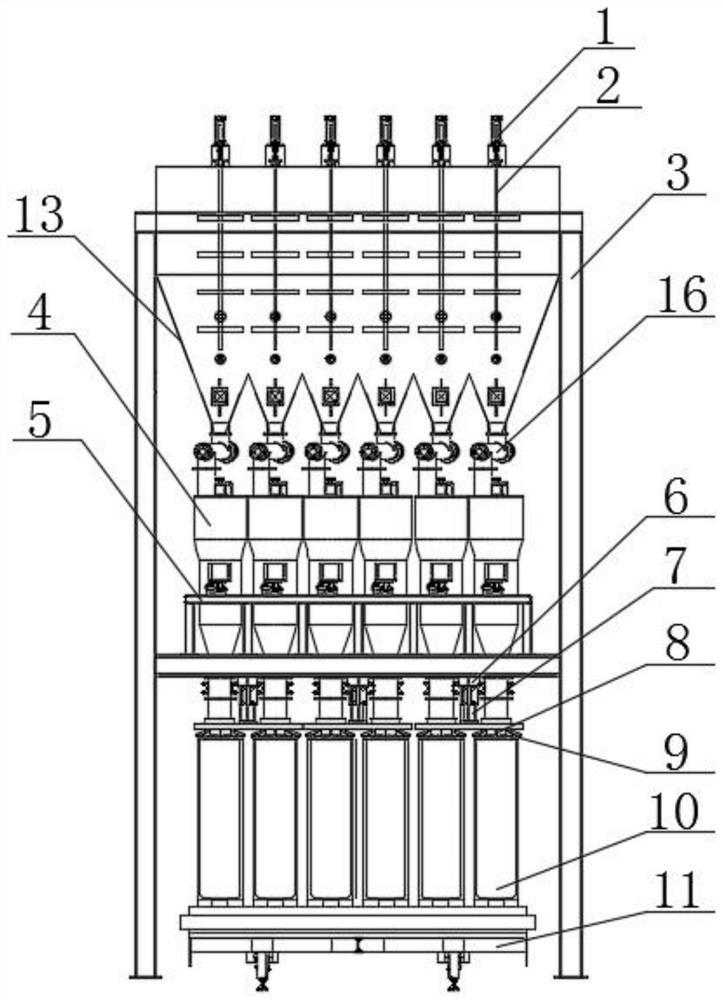

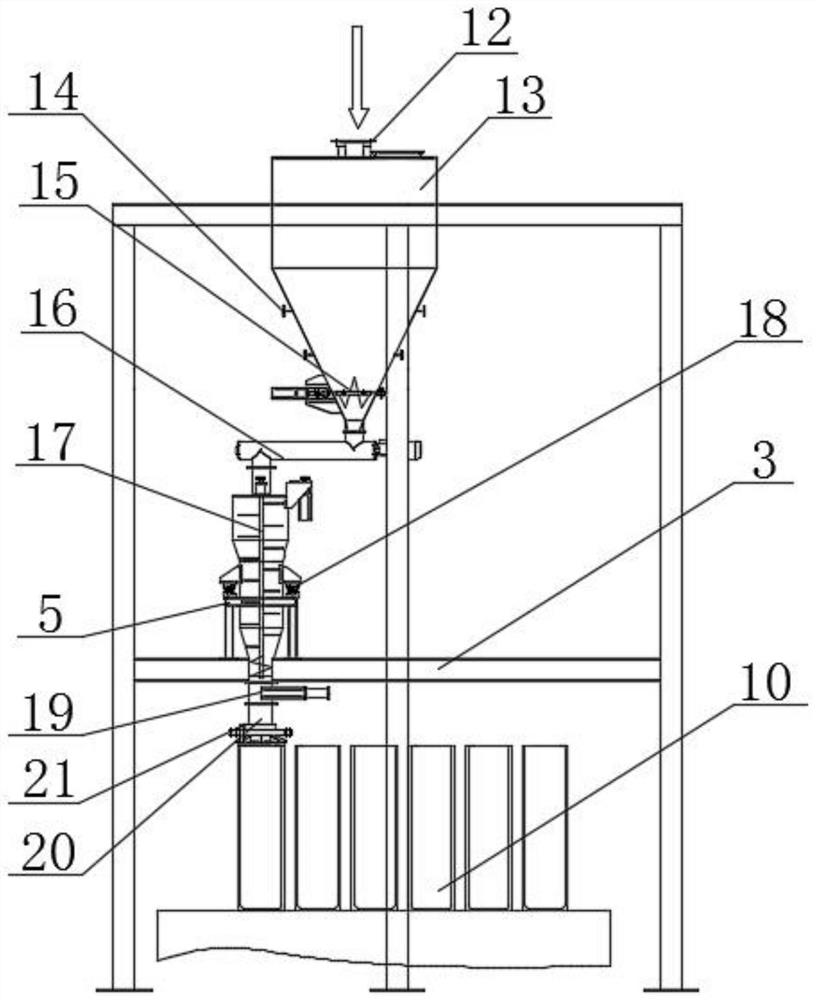

[0027] see Figure 1-2 , the present embodiment provides a graphite negative electrode material crucible automatic charging system, comprising a multi-layer frame 3, a small frame 5 and a crucible 10, the small frame 5 is fixedly connected to the middle position of the multi-layer frame 3, and the top of the multi-layer frame 3 A silo 13 is erected, the upper part of the silo 13 is provided with a feeding port 12, the upper part of the silo 13 is fixedly installed with an arch-breaking lifting cylinder 1, and the lower output end of the arch-breaking lifting cylinder 1 is located in the material silo 13 and is equipped with an arch-breaking pull rod 2. The side wall of the silo 13 is provided with multiple compressed air ports 14. If necessary, compressed air can be sent to the silo 13 through the compressed air ports 14. The materials can be blown loose by using the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com