Pressure detection device for track inspection robot and track inspection robot

A technology of inspection robots and detection devices, applied in the field of robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

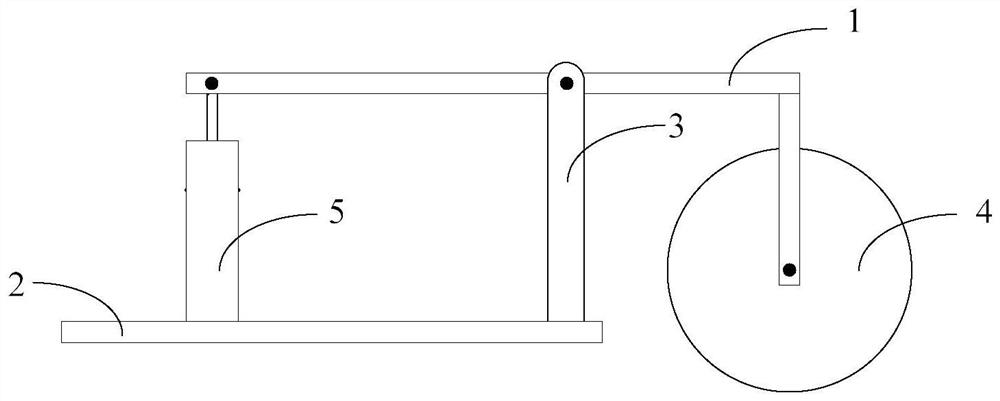

[0036] figure 1 It is a schematic structural diagram of a pressure detection device for a track inspection robot in an embodiment of the present application. like figure 1 As shown, the pressure detection device for the track inspection robot in this embodiment includes: a first support arm 1, a second support arm 2, and a first connecting rod 3;

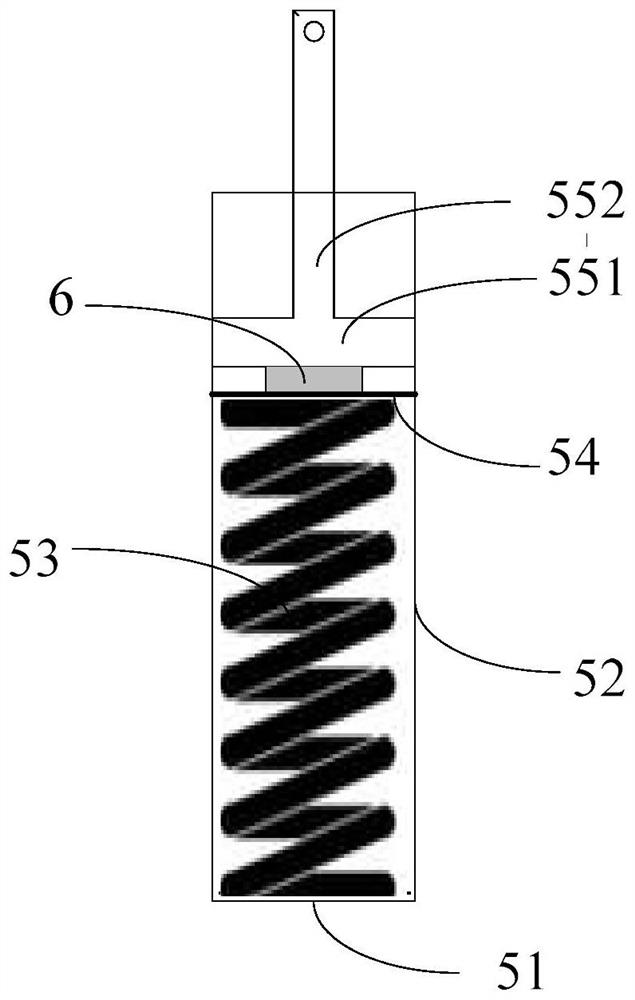

[0037] One end of the first support arm 1 is equipped with a detection wheel 4, and the other end is provided with an elastic compression assembly 5. The first support arm 1 is rotatably connected with the elastic compression assembly 5. A pressure sensor 6 is arranged in the elastic compression assembly 5. The first support The middle part of the arm 1 is rotatably connected to one end of the first connecting rod 3; the detection wheel 4 can rotate and walk on one side of the rail surface or the rail waist;

[0038] One end of the second support arm 2 is vertically and fixedly connected to the other end of the connecting rod 3 , ...

Embodiment 2

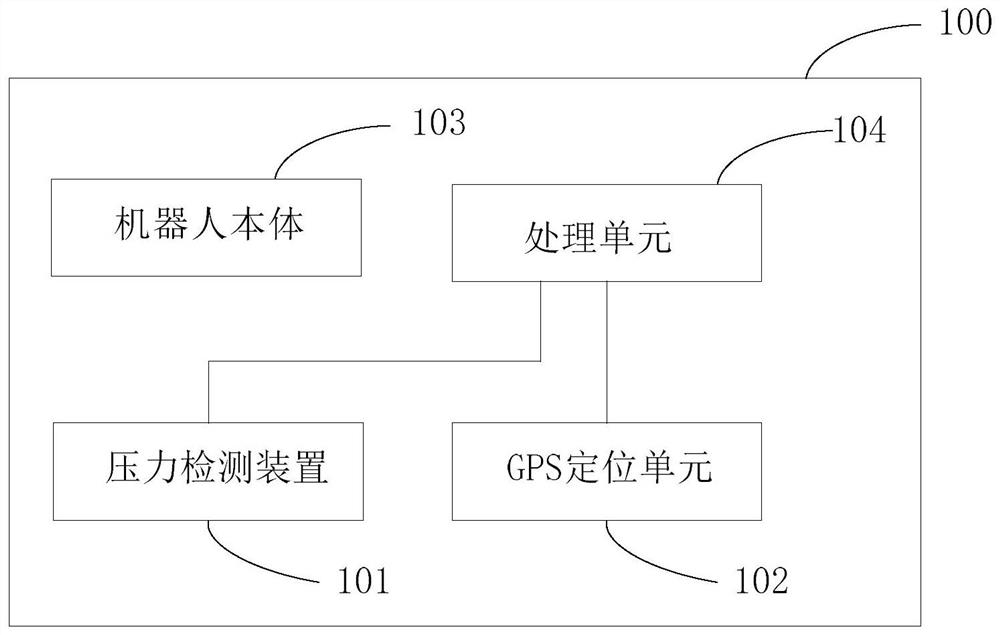

[0049] The second aspect of the present application provides a track inspection robot 100, image 3 It is a schematic structural diagram of the track inspection robot in another embodiment of the present application, such as image 3 As shown, the track inspection robot 100 includes: at least one pressure detection device 101 as described in any one of the first aspect above, and a robot body 103 capable of traveling on at least one rail, a positioning unit 102, and a processing unit 104;

[0050] The pressure detection device 101 is arranged on the robot body 103, and is used to detect the pressure exerted by the detection wheel of the rail inspection robot 100 on the surface or the rail waist of the rail to be detected when walking on the surface or the rail waist;

[0051] The positioning unit 102 is arranged on the robot body 100 and is connected with the processing unit 104, and is used to collect the coordinate information of the current position in real time, and send t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com