Device and method for automatically removing glue from mobile phone

A mobile phone and equipment technology, applied in the field of automatic dismantling of mobile phones, can solve the problems of unclean cleaning of hot melt adhesive, low recycling rate of mobile phone parts, and reduced production efficiency, so as to improve dismantling income, high glue removal efficiency, and improve recycling rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as figure 1 The present invention shown is a device and method for automatically removing the back cover of the mobile phone and the hot melt adhesive on the parts during the automatic disassembly process of the mobile phone.

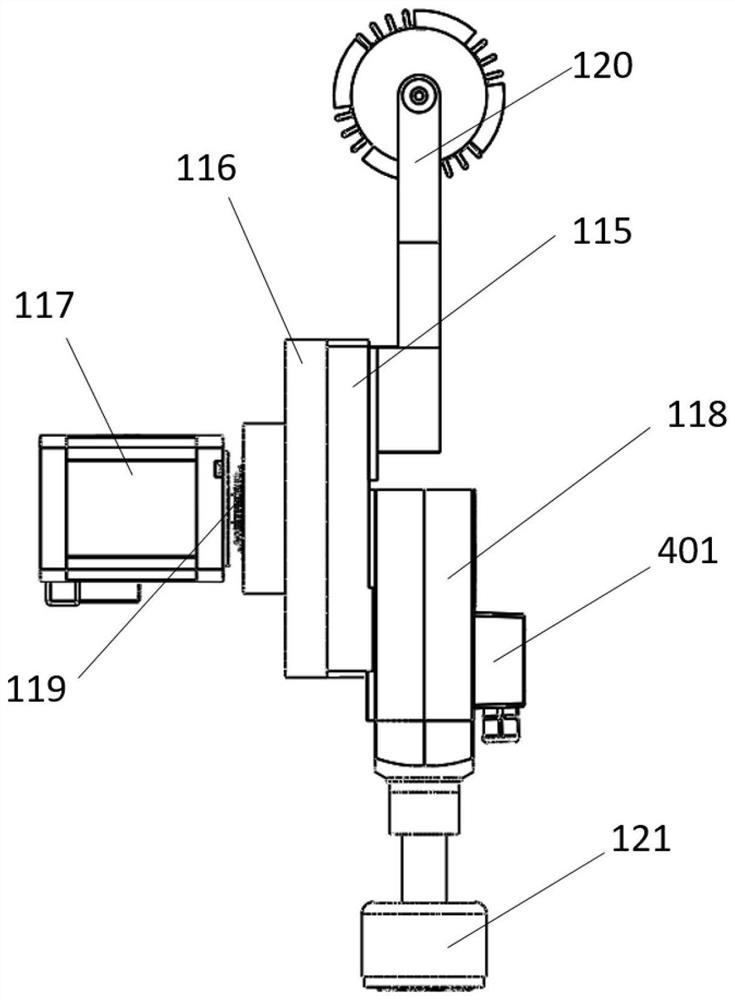

[0039] The equipment includes a glue removal module 1 , a feeding module 2 , a pressure sensing module 3 , a laser sensing module 4 , a control module 5 , a brush cleaning module 6 and a frame 7 .

[0040] The stepper motor 117 in the glue removal module 1 is fixed on the lower side of the Z-axis component of the feed module 2, and the feed module 2 is fixed on the bracket of the frame 7. The pressure sensing module 3 is fixed on one side of the frame 7 and includes a pressure display 301 , a pressure sensor 1 302 , a pressure sensor 2 303 , and a signal analyzer 304 . The control module 5 is fixed on the upper side of the frame 7 and the lower side of the pressure display 301 . The laser sensor module 4 is fixed on one side of the brush r...

Embodiment 2

[0055] This solution is a chemical degumming method. The specific degumming process is to use an organic solvent to dissolve the hot melt adhesive and then wipe it off with a sponge. Such as Figure 6 As shown, the chemical degumming module 8 is installed at the position of the original mechanical degumming module 1, and the control module 5 controls the feed module 2 to drive the chemical degumming module 8 to complete the degumming action. The sponge block 803 of the degumming module 8 is lowered to the degumming interface along the Z-axis direction, and the entire degumming area is wiped twice along the X and Y-axis directions.

[0056] Such as Figure 7 As shown, the chemical glue removal module 8 includes a liquid storage bin 801 , a liquid outlet cover 802 and a sponge block 803 . Inject the diluted acetone debonding agent from the infusion hole on the upper side of the liquid storage tank. In order not to damage the parts, a large number of experiments were carried ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com