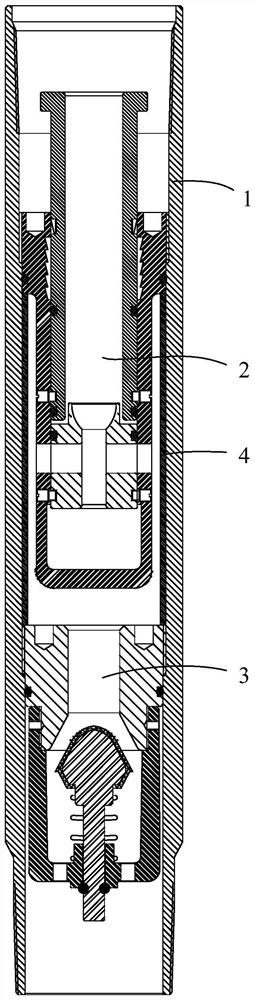

Backflow prevention device

A technology for preventing backflow and jamming, which is used in wellbore/well components, sealing/packaging, earth-moving drilling, etc., and can solve the problems of cumbersome construction steps and long construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

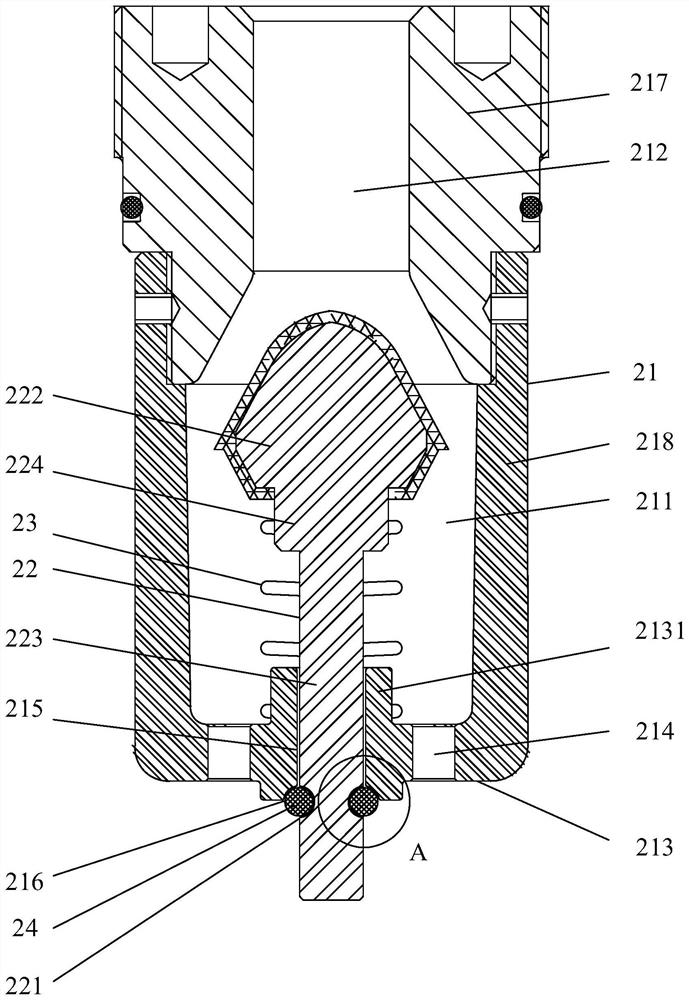

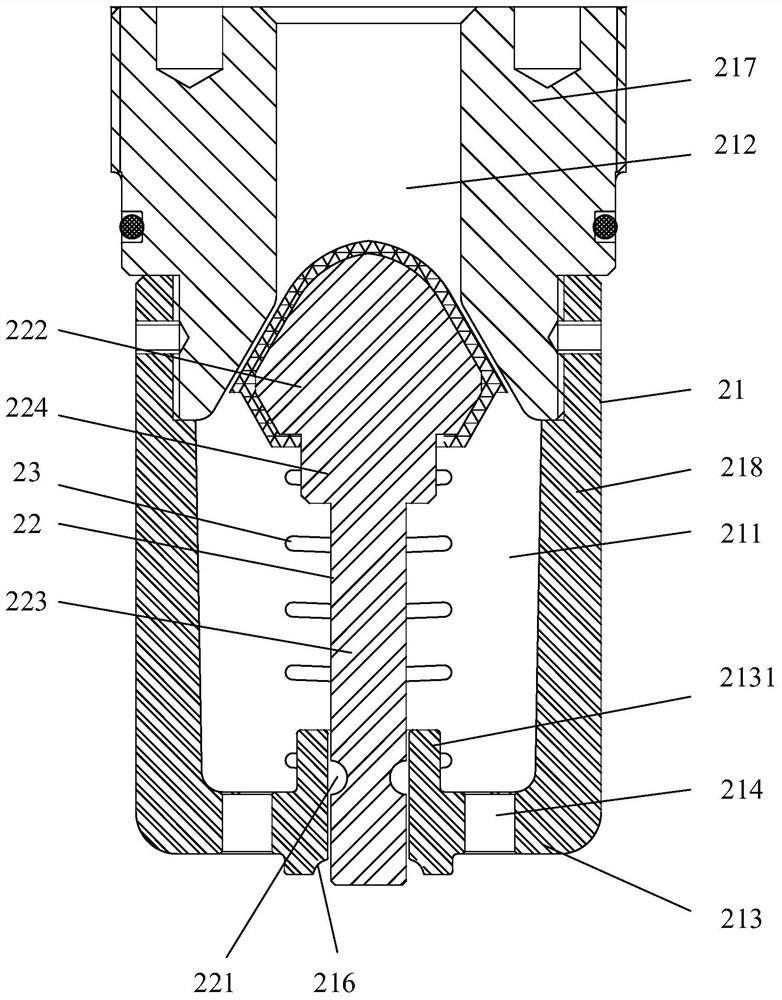

[0038] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

[0039]Cementing operation is a routine construction step in the process of oil and gas development, which can effectively reduce the construction difficulty and construction cost of oil and gas development. Since the cementing operation needs to be realized based on the liner, the liner operation needs to be performed before the cementing operation is performed.

[0040] In the related technology, after the tail pipe is lowered to a designated position, the pressure is suppressed by throwing a ball, so as to realize the mounting of the hanger, so as to complete the fixing of the tail pipe on the casing. After the liner is fixed, cement slurry is pumped to the liner through the surface cementing equipment. In order to prevent the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com