High-impact antistatic PMMA (polymethyl methacrylate) composition as well as preparation method and application thereof

A composition and antistatic technology, which is applied in the field of high impact and antistatic PMMA composition and its preparation, can solve the problems of poor antistatic performance and poor toughness, achieve excellent toughness, excellent antistatic performance, avoid rigidity and Transparency drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~17

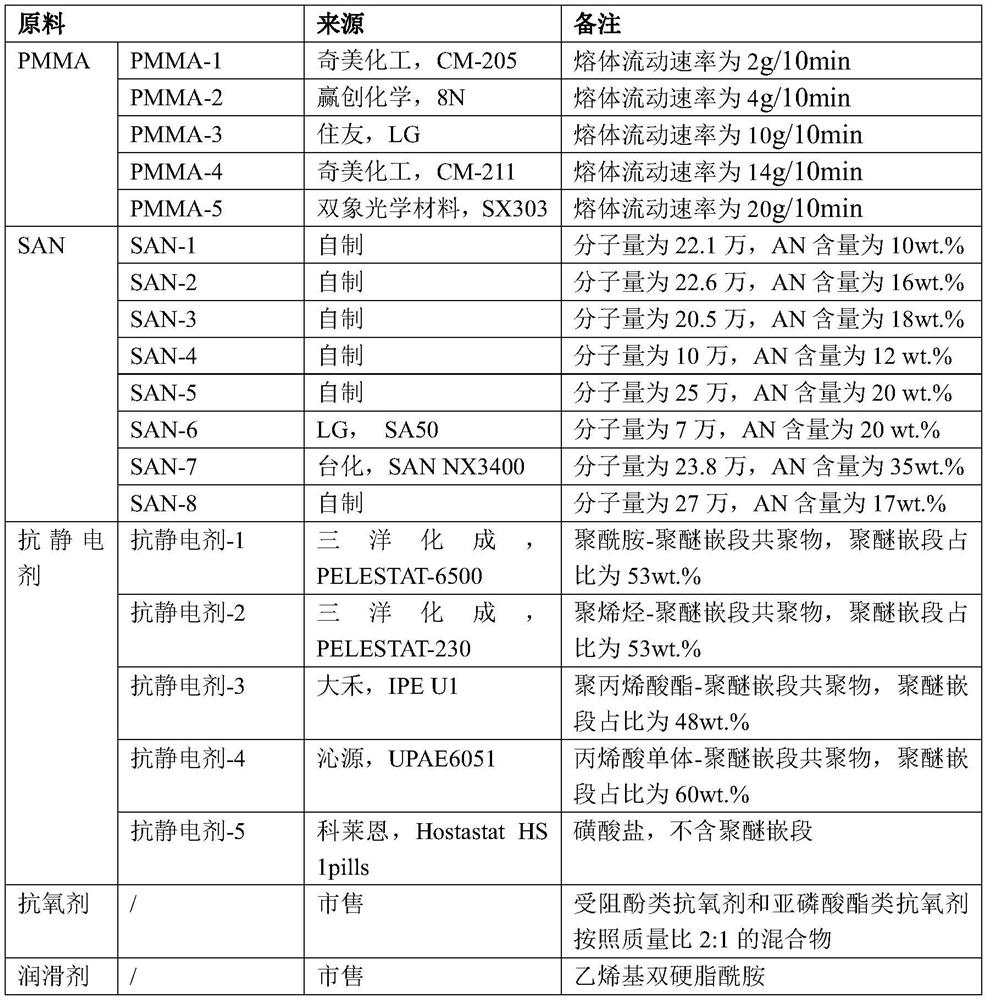

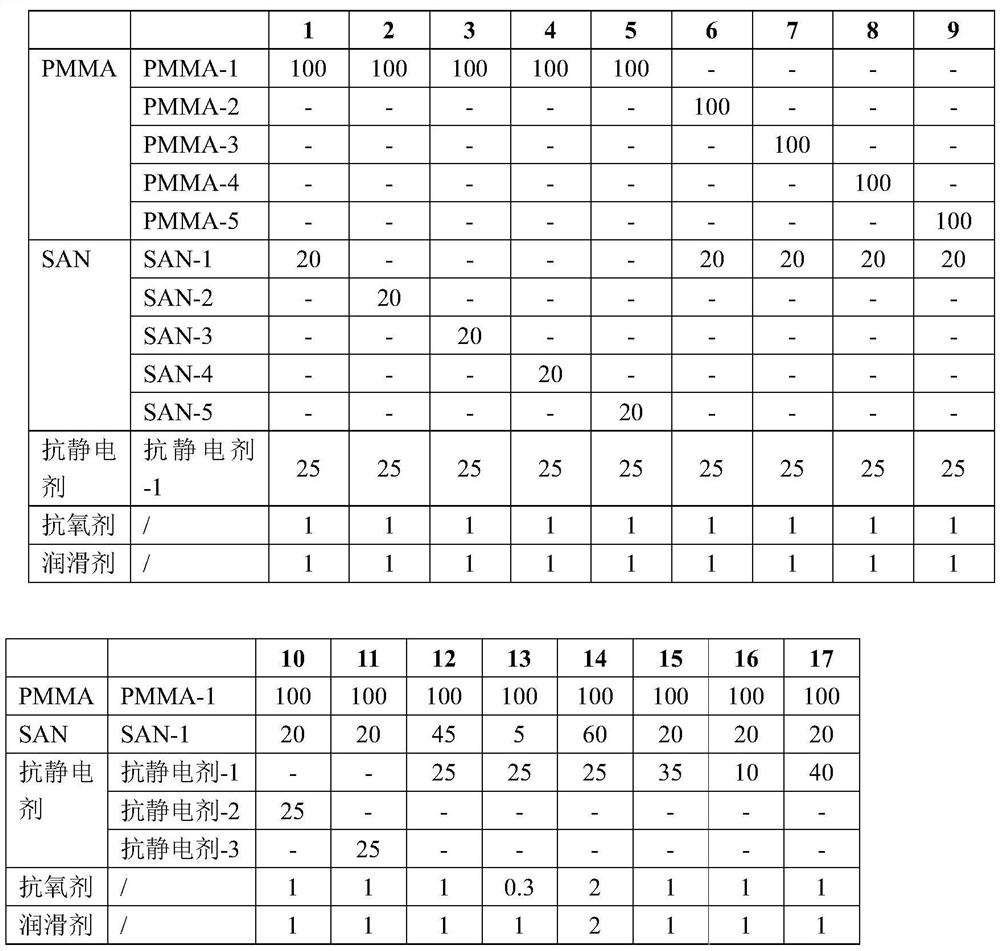

[0055] Embodiments 1 to 17 provide a PMMA composition respectively, the component contents are shown in Table 1, and the preparation method is as follows:

[0056] After mixing each component according to Table 1, add to a twin-screw extruder, and extrude and granulate through melt mixing to obtain a PMMA composition;

[0057]The temperature of the first to second zone of the twin-screw extruder is 120-170°C, the temperature of the third to fifth zone is 160-180°C, and the temperature of the sixth to tenth zone is 170-190°C.

[0058] The component content (parts by weight) of the PMMA composition of table 1 embodiment 1~17

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com