Tower crane attachment frame

A technology for attaching frames and tower cranes, which is applied in the connection of poles, connecting components, cranes, etc., and can solve the problems of single and unadjustable attachment frames.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

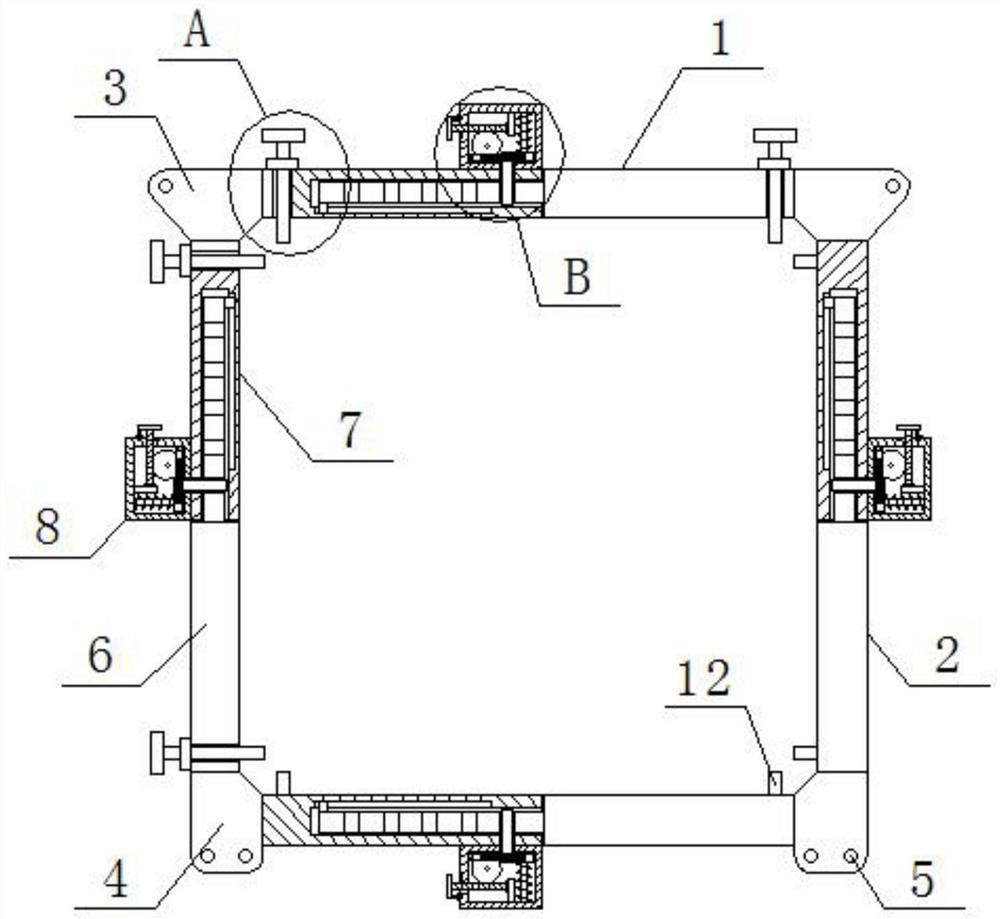

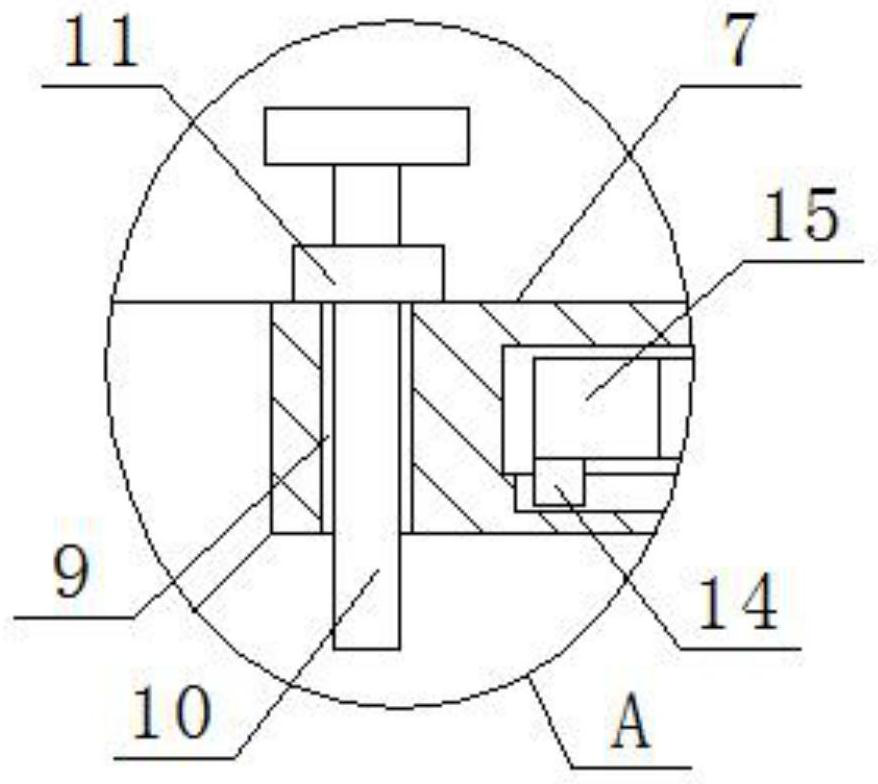

[0027] Reference Figure 1-9 , tower crane attachment frame, comprising a set of transverse adjustment components 1 and a set of longitudinal adjustment components 2, wherein the upper transverse adjustment assembly 1 and the two longitudinal adjustment components 2 are fixedly connected to a single-hole ear plate 3, the lower lateral adjustment assembly 1 and two longitudinal adjustment components 2 are fixedly connected to the double-hole ear plate 4, single-hole ear plate 3 and a double-hole ear plate 4 respectively opened with a pin hole 5 and two pin holes 5, the lateral adjustment assembly 1 and the longitudinal adjustment component 2 both include a square rod 6 and a square tube 7, Square tube 7 outer wall near the square rod 6 side fixed connection to the adjustment shell 8, the upper transverse adjustment assembly 1 and the left longitudinal adjustment assembly 2 are opened with two screw holes 9, screw hole 9 inner thread is installed with adjustment screw 10, adjustment ...

Embodiment 2

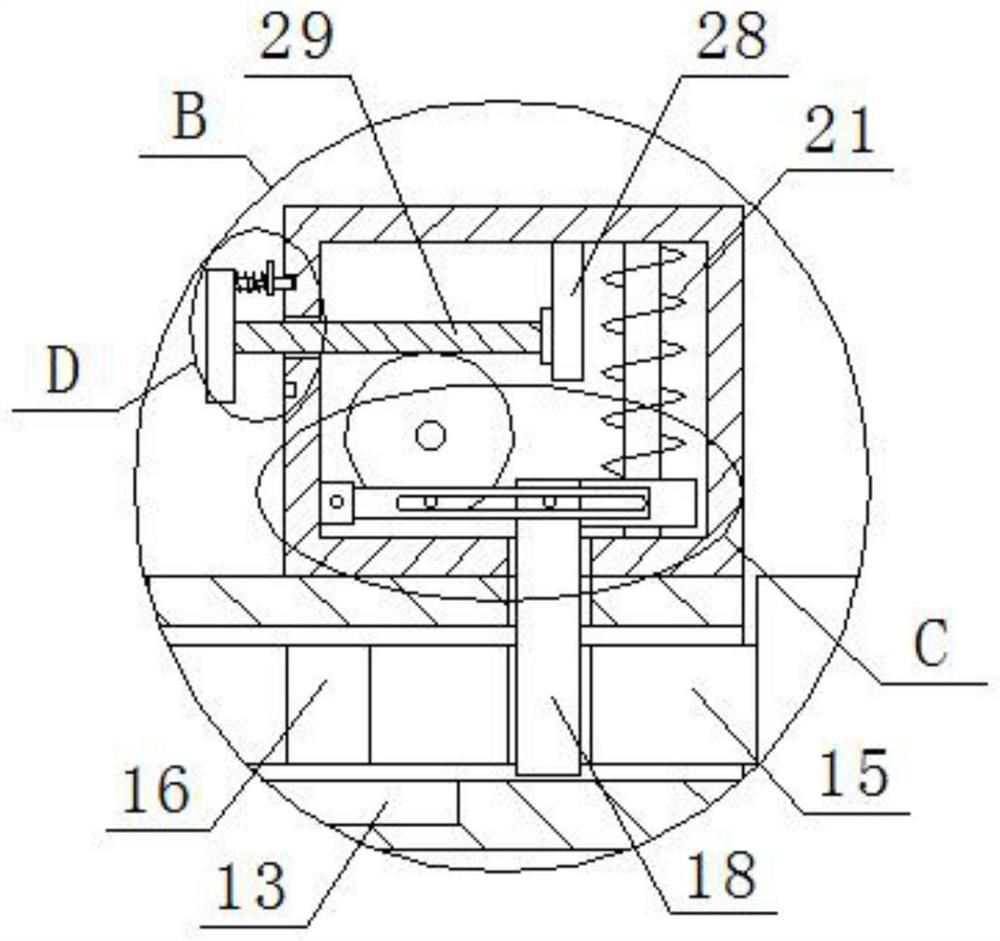

[0029] In the present invention, the waist groove rod 23 slide is mounted with no. 1 bump 24 and no. 25, and the no. 25 bump 25 is fixedly connected to the side of the latch 18, the no. 1 bump 25 rotates, can drive the waist slot rod 23 to rotate, and then drive the no. 2 brak 25 to move, and then drive the latch 18 to move.

[0030] In the present invention, the inner wall of the adjusting shell 8 is rotated to connect to one end of the straight rod 26, the other end of the straight rod 26 is provided with a worm gear 27, and the No. 1 bump 24 is fixedly connected to the side of the worm gear 27, the worm gear 27 rotates, can drive the No. 1 bump 24 to rotate.

[0031] In the present invention, the adjustment shell 8 is fixed to the inner wall of one side away from the square tube 7 is fixedly connected to the mounting block 28, the mounting block 28 is rotated from the side of the straight pipe 20 is connected to the worm 29.

[0032] In the present invention, the worm 29 is ext...

Embodiment 3

[0037] Reference Figure 1-9 , tower crane attachment frame, comprising a set of transverse adjustment components 1 and a set of longitudinal adjustment components 2, wherein the upper transverse adjustment assembly 1 and the two longitudinal adjustment components 2 are welded between a single-hole ear plate 3, the lower lateral adjustment assembly 1 and two longitudinal adjustment components 2 are welded between the double-hole ear plate 4, single-hole ear plate 3 and a double-hole ear plate 4 are chiseled on a pin hole 5 and two pin holes 5, the lateral adjustment assembly 1 and the longitudinal adjustment assembly 2 both include a square rod 6 and a square tube 7, Square tube 7 outer wall near the side of the square rod 6 welded with a control shell 8, the upper transverse adjustment assembly 1 and the left longitudinal adjustment assembly 2 are chiseled with two screw holes 9, screw hole 9 inner thread is installed with adjustment screw 10, adjustment screw 10 on the thread sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com