Gate valve producing, manufacturing and assembling equipment and assembling method

A technology for assembling equipment and gate valves, which is used in manufacturing tools, workpiece clamping devices, hand-held tools, etc., can solve the problems of inaccurate alignment of the upper die seat and the lower die seat, frequent operations, and increased difficulty for staff. To improve the clamping effect, ensure the accuracy, and not easy to slide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

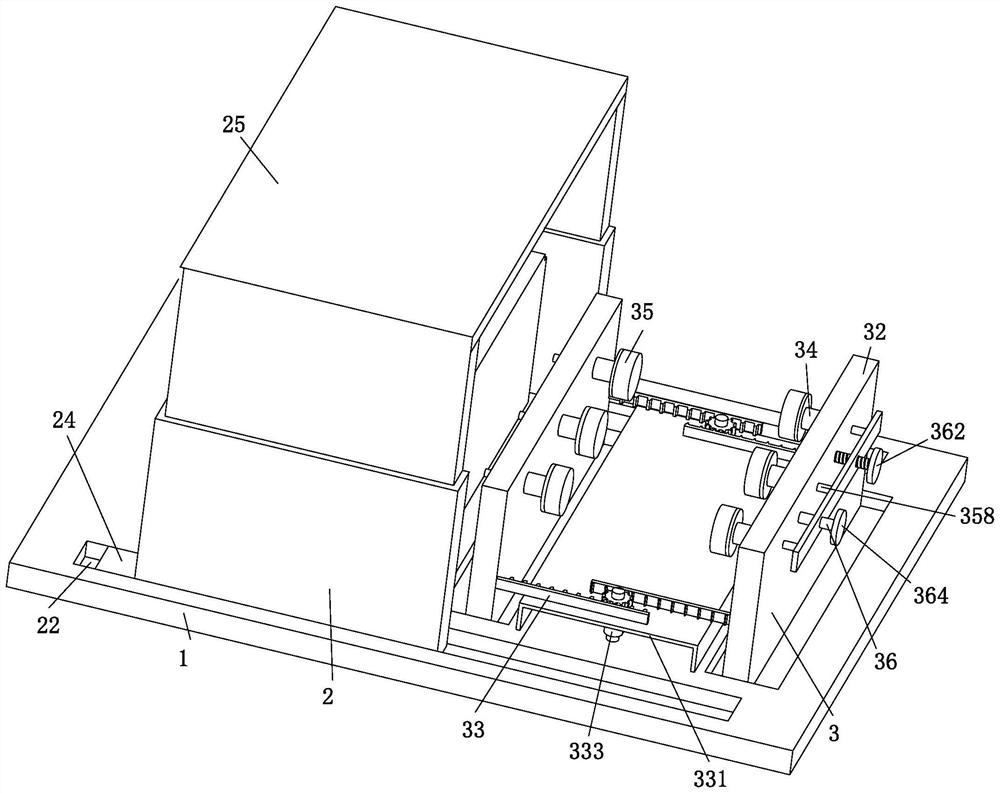

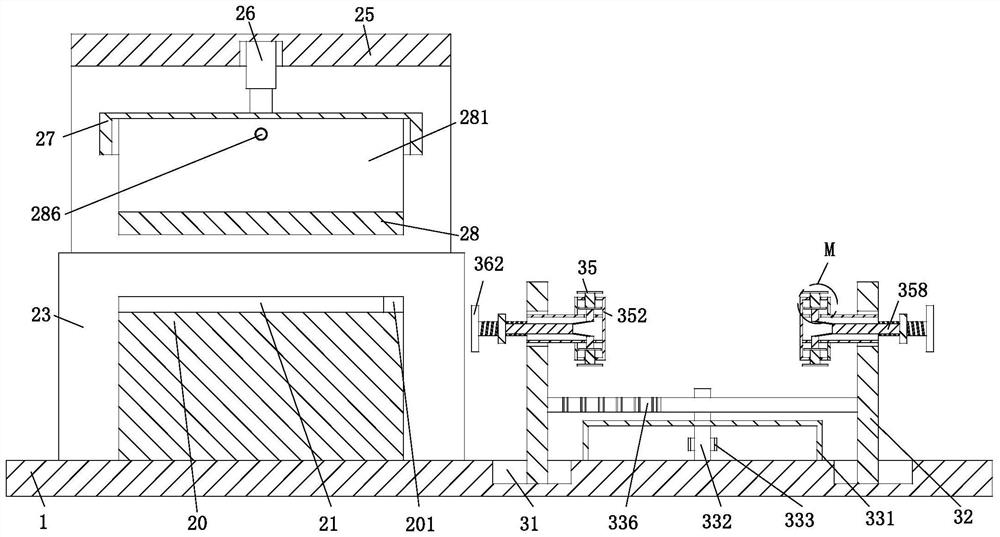

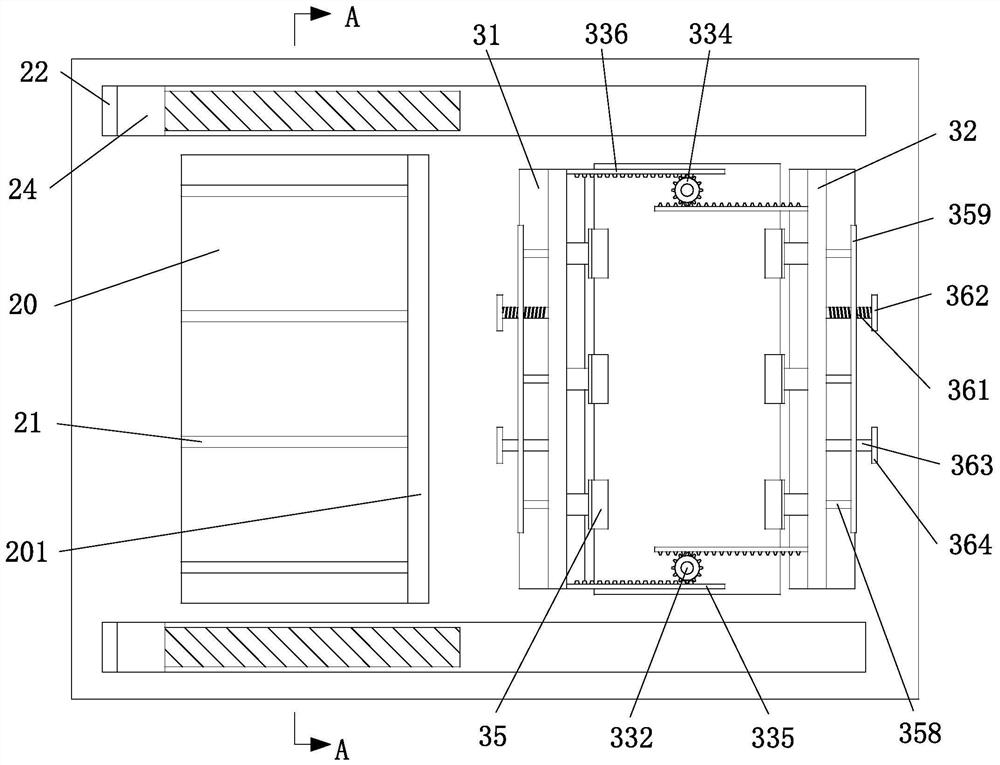

[0030] refer to Figure 1-9 As shown, a gate valve production and assembly equipment includes a workbench 1, a fixing device 2 and a moving device 3, and the top of the workbench 1 is sequentially provided with a fixing device 2 and a moving device 3 from left to right;

[0031]Described fixing device 2 comprises support table 20, isolation baffle plate 21, sliding groove 22, telescopic bracket plate 23, electric slider 24, fixed support plate 25, electric push rod 26, square plate 27, mobile frame 28 and fixed Frame 29, the top of the workbench 1 is fixedly insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com