PU anti-collision flax fiber cork wood skateboard core veneer

A flax fiber and balsa technology, which is used in skateboards, skating, roller skates, etc., can solve the problems of limited buffering effect and damage to the internal structure of the skateboard, so as to improve the buffering effect, improve the impact resistance and ensure the structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

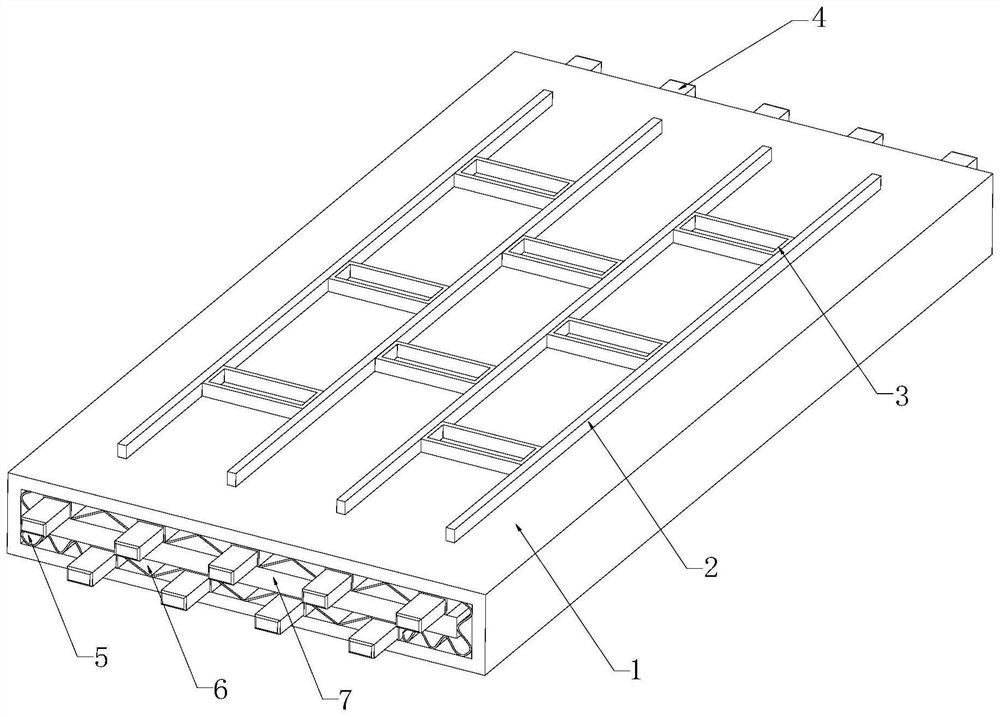

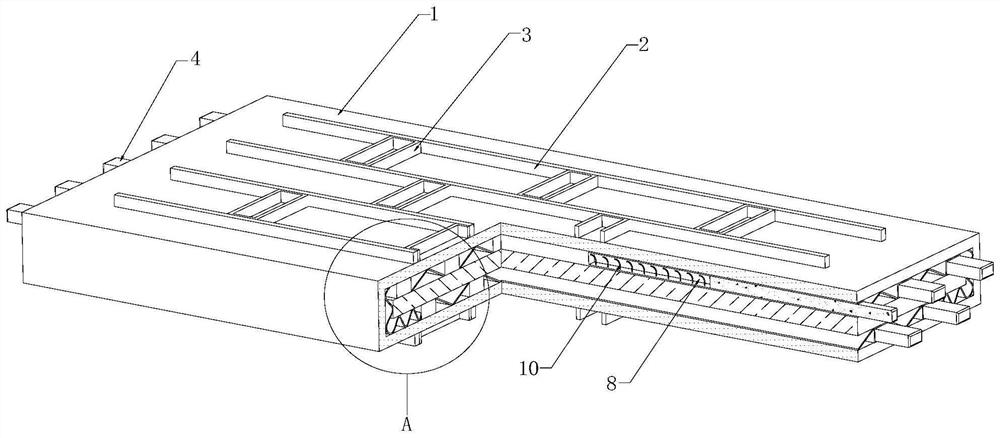

[0037] Such as Figure 1-Figure 6 As shown, a PU anti-collision flax fiber balsa skateboard core board includes an inner core board 7 with a flat structure as a whole. Both are provided with clamping components, and a plurality of buffer components are installed on the opposite side of the inner core plate 7 and the outer core shell 1, and the plurality of buffer components are connected to the opposite side of the outer core shell 1 and the inner core plate 7. Reinforcement components, the two ends of the inner core plate 7 and the opposite side of the outer core shell 1 are installed with side reinforcement components;

[0038] The buffer assembly includes a plurality of square sleeves 8 fixedly installed on the opposite side of the inner core plate 7 and the outer core shell 1, and the middle end of the square sleeve 8 is provided with a partition block, and the upper and lower square sleeves 8 Staggered distribution, the inner wall of the square sleeve 8 and the two sides...

Embodiment 2

[0049] Based on the PU anti-collision flax fiber balsa skateboard core board provided in the first embodiment of the present application, the second embodiment of the present application proposes another PU anti-collision flax fiber balsa wood skateboard core board. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0050] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

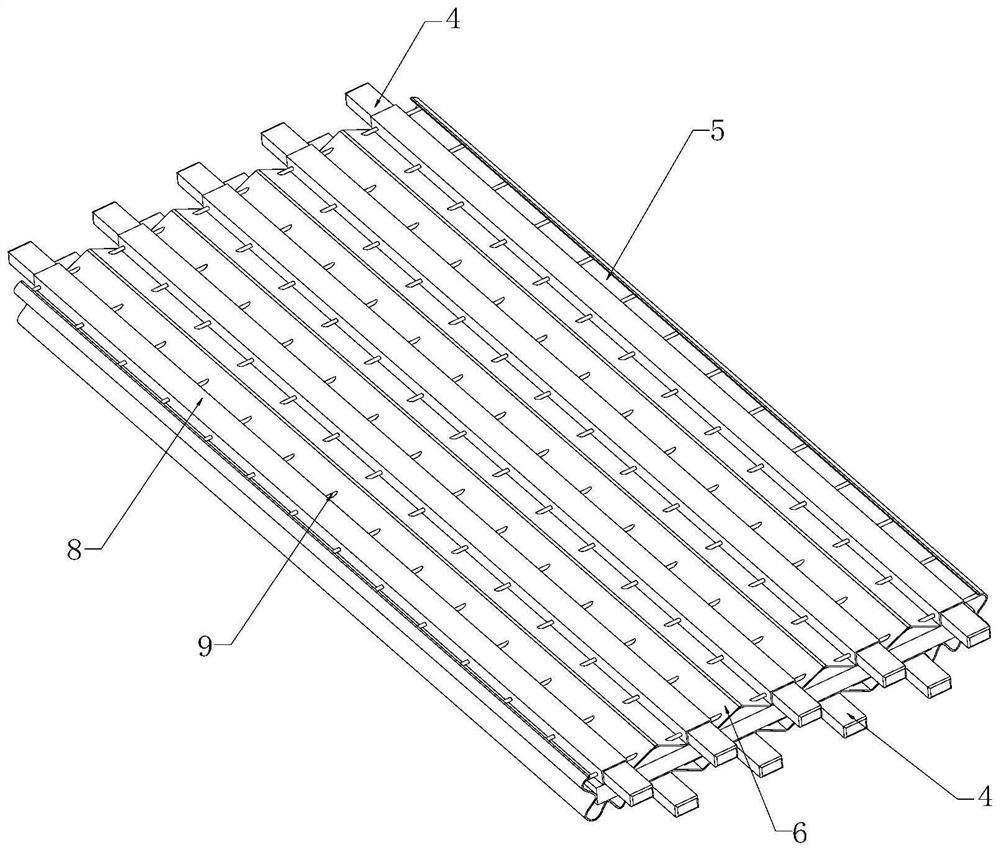

[0051] Such as Figure 7-Figure 8 As shown, the second embodiment also includes a plurality of connecting fins 19 fixedly connected between the outer walls of the two ends of the side cavity block 11 and the square mouth sleeve 8, and the extension lines of one end of the plurality of connecting fins 19 converge at one point and are located on the outside A plurality of grid co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com