Centrifugal seed/fertilizer dual-purpose broadcaster

A dual-purpose, centrifugal technology, used in fertilizer spreaders with centrifugal wheels, planter parts, applications, etc., can solve the problems of poor spreading uniformity, large coefficient of variation, and difficulty in accurate spreading, and achieves improved spreading uniformity and spreading. The effect is uniform and the utilization rate is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that in this embodiment, terms such as "up", "down", "left", and "right" are all carried out in accordance with the orientation or positional relationship shown in the drawings or the usual placement of the product of the invention in use. description, but not limitation of the present invention.

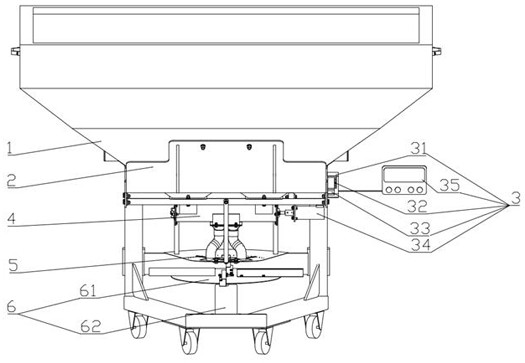

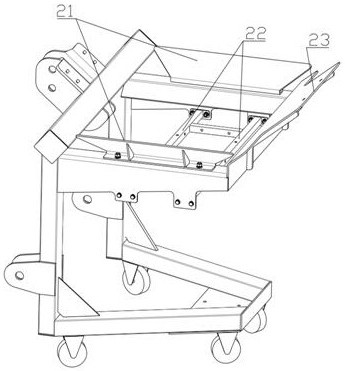

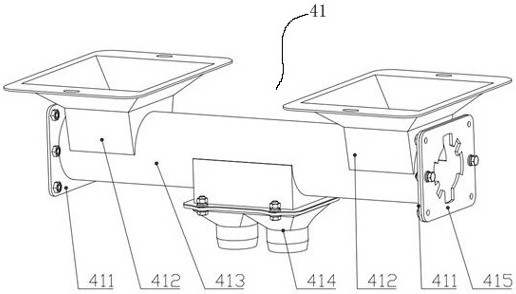

[0028] Attached below Figure 1-8 The present invention is further described in detail: a centrifugal seed / fertilizer dual-purpose spreader, including a material box 1, a frame 2, an electric control system 3, a feeding device 4, a blanking adjustment mechanism 5 and a spreading device 6; figure 1 As shown, the material box 1 is fixedly installed on the top of the frame 2; the feeding device 4 is installed on the bottom of the material box 1, and the feeding device 4 includes a common feeding assembly 41, a fertilizer feeding assembly 42 and a seed feeding assembly 43, and the feeding common assembly 41 communicates with the spreading device 6 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com