Faucet

A faucet and valve seat technology, applied in the field of faucets, can solve the problems of high cost and high precision of valve core installation force, and achieve the effect of reducing material cost and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] Certain directional terms used hereinafter to describe the drawings, such as "inner," "outer," "above," "below" and other directional terms, are to be understood those directions involved in the drawing. Unless otherwise specified, the directional terms described in this specification basically follow the conventional directions understood by those skilled in the art.

[0028] The terms "first", "first", "second", "second" and similar terms used in the present invention do not indicate any order, quantity or importance in the present invention, but Used to distinguish one part from other parts.

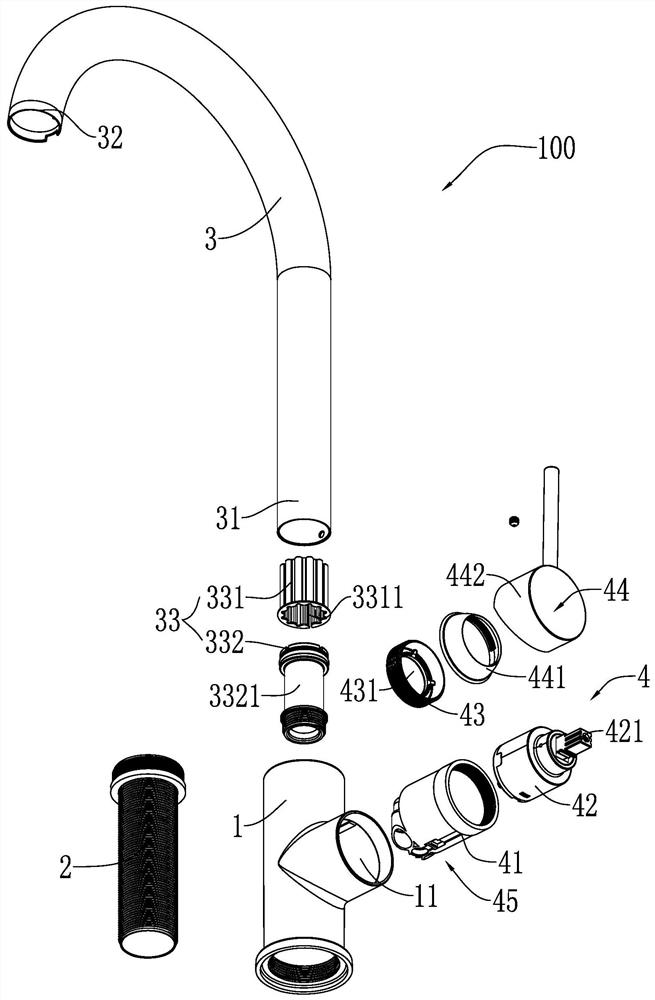

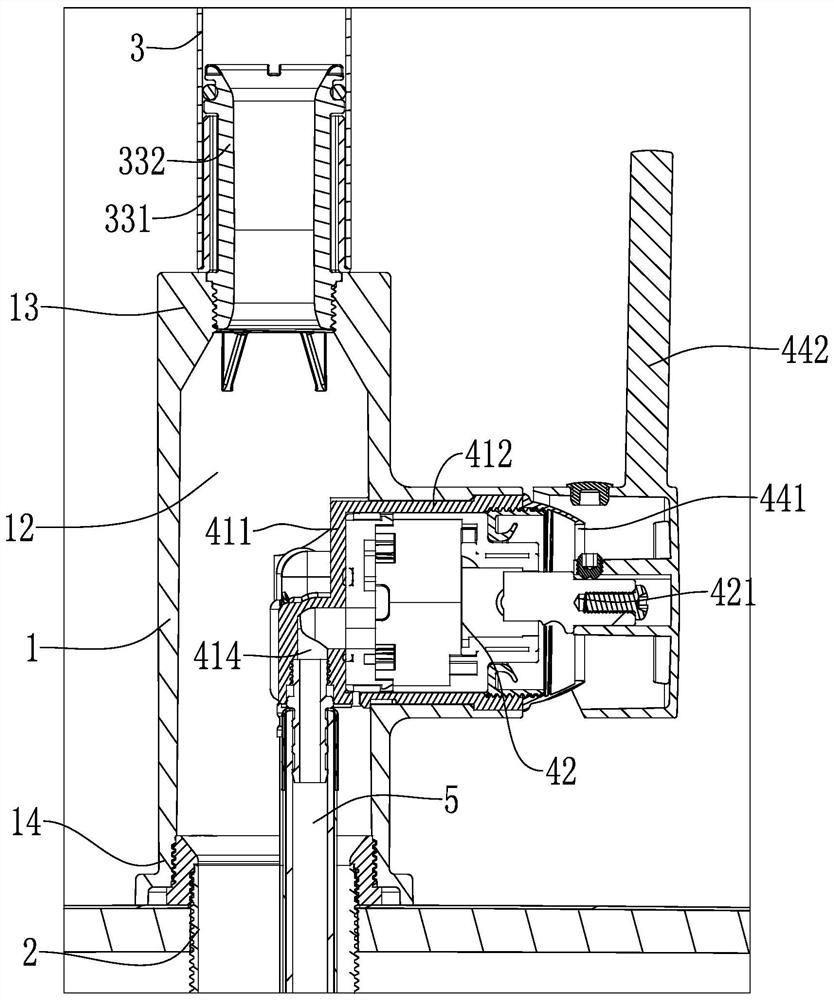

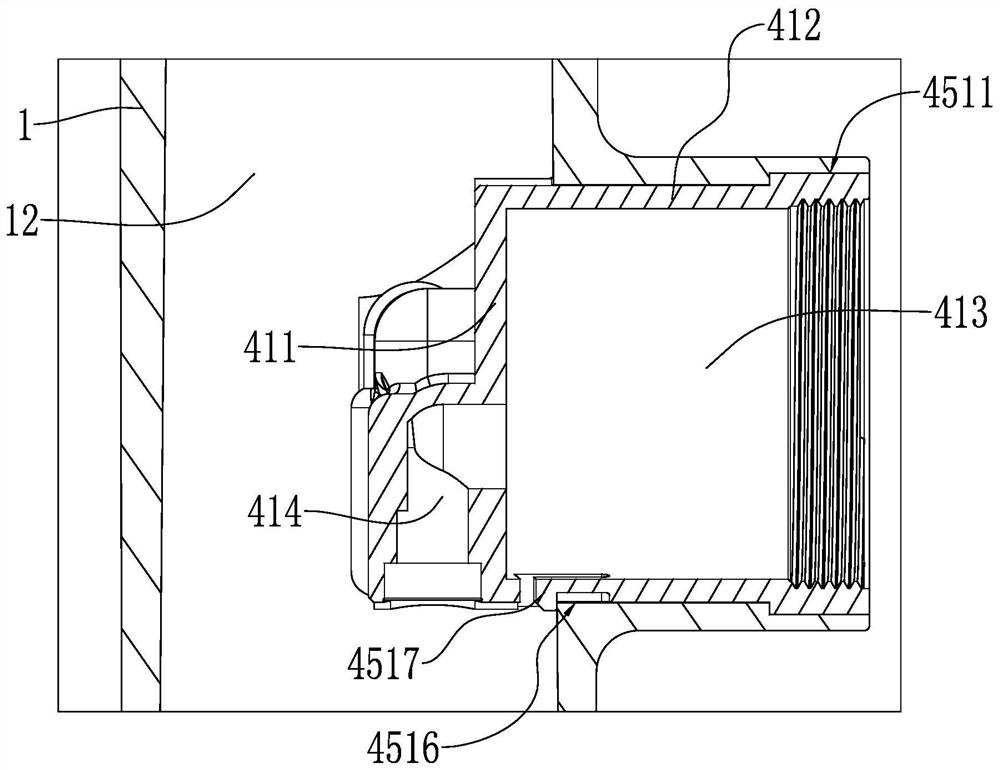

[0029] refer to Figure 1-Figure 8 , a faucet 100, the faucet 100 includes a casing 1, the casing 1 is a three-way pipe structure, the casing 1 includes a horizontally extending installation groove 11 and a vertically extending and penetratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com