Normal-temperature flotation method for high-calcium low-grade scheelite

A low-grade, scheelite technology, applied in the field of scheelite, can solve the problems of low grade of scheelite flotation concentrate at room temperature, high energy consumption for heating and selection, and high labor intensity of workers. Significant effects of ore feeding in warm operation, improvement of grade and recovery rate, energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

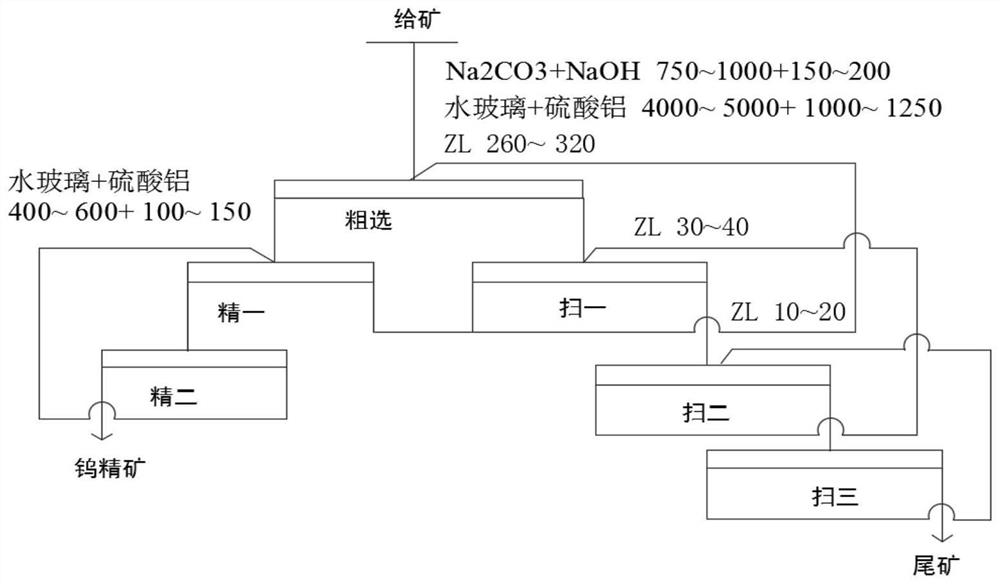

[0020] The invention provides a high-calcium and low-grade scheelite flotation method at normal temperature, which can greatly improve the grade and recovery rate of tungsten concentrate obtained from scheelite flotation at normal temperature, reduce the amount of ore fed to the selection and heating operation, and reduce the labor of workers. Labor intensity, while saving energy and reducing consumption, please refer to figure 1 , including mine feeding;

[0021] Further, the specific process flow is:

[0022] S1: Scheelite normal temperature flotation feeding ore grinding fineness is -200 mesh, accounting for 70%, using one roughing, two beneficiation, three sweeping, closed-circuit middle ore return process in sequence;

[0023] S2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com