Handle mechanism of fishing rod

A technology for handles and fishing rods, applied in fishing rods, fishing, applications, etc., can solve cumbersome problems, and achieve the effect of uniform force shape and not easy to skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

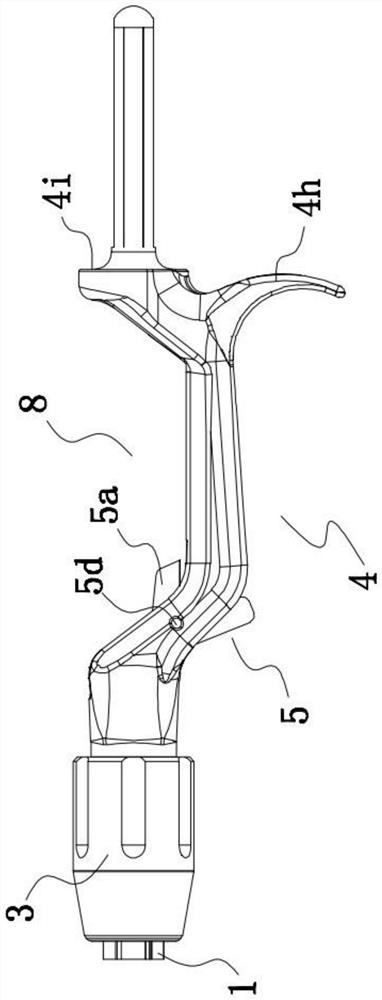

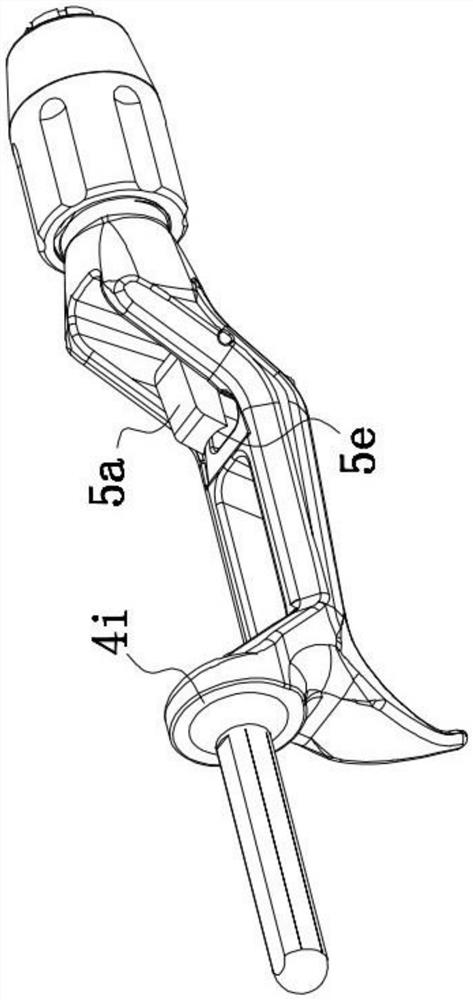

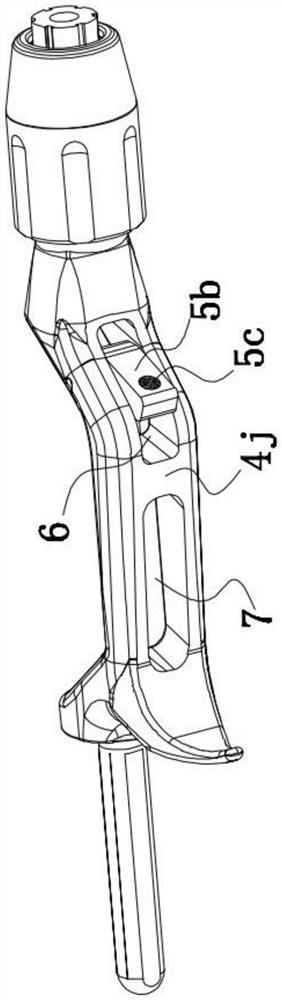

[0046] In order to achieve the purpose of the present invention, a fishing rod handle mechanism includes: a handle part 4, which is grasped by the hand; a quick-loading mechanism includes a central column 1, a pressure ring 2, and a cover 3, and the quick-loading mechanism is located between the handle part 4 and the The junction of fishing rods; the central column 1 has several through grooves 1a and several blind grooves 1b in an annular array on its own circumference, and the blind grooves 1b are only connected to the same axial end of the central column 1; The receiving hole 1c fixed with the fishing rod; the pressure ring 2 is equipped with a through cavity 2c for the central column 1 to pass through, and there are several convex ribs 2a in a circular array on the inner wall of the through cavity 2c, and the convex ribs 2a are connected with the through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com