Superheated water circulation loop for tokamak vacuum baking

A circulating loop and tokamak technology, applied in thermonuclear fusion reactors, nuclear reactors, nuclear power generation, etc., can solve problems such as inability to meet demand, and achieve the effect of convenient volume flow and mass flow, mature process technology, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

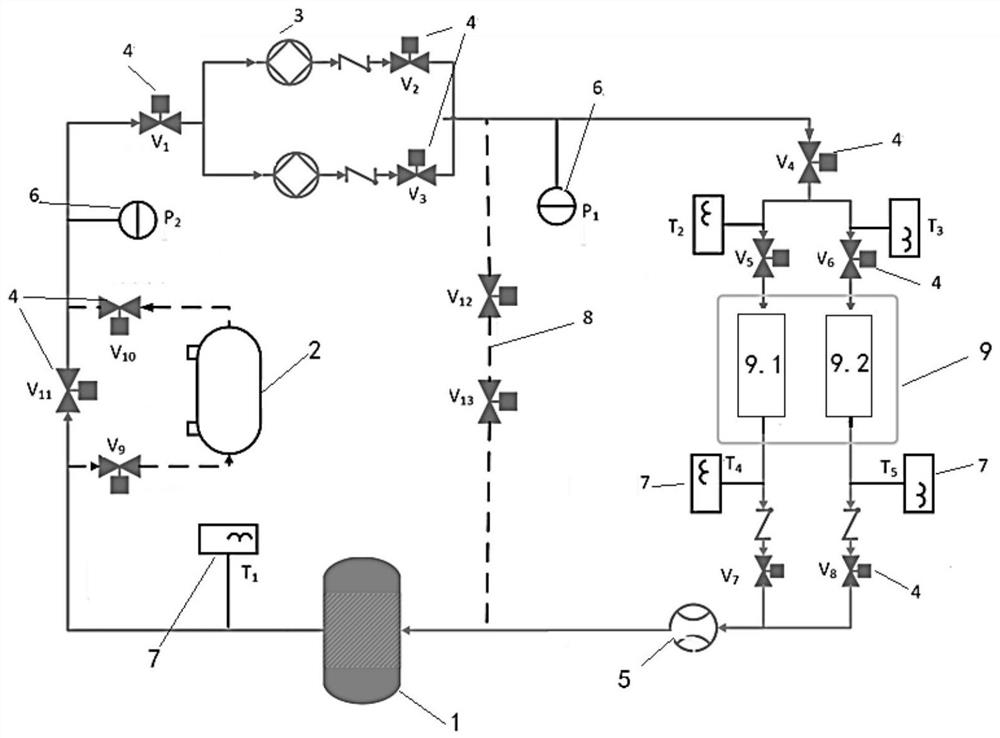

[0035] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

[0036] Electric heater 1, expansion tank 2, water pump 3, pipelines in the circuit connecting the above equipment, regulating valves 4 installed in corresponding positions in the pipelines, and monitoring components such as pressure gauges 6 and thermometers 7;

[0037] Such as figure 1 As shown, the superheated water circulation loop used for tokamak vacuum baking includes:

[0038] The electric heater 1 and the expansion tank 2 connected in series through pipelines, the two-way parallel water pump 3 installed on the outlet pipeline of the expansion tank 2, the load 9 to be baked installed on the inlet pipeline of the electric heater 1;

[0039] A thermometer 7 (T) is installed on the outlet pipeline of the electric heater 1 1 );

[0040] An adjustment bypass 8 is provided between the parallel outlet of the two-way parallel water pump 3 and the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com