Abrasion rapid detection device and method based on abrasive particle image automatic acquisition and analysis

A technology of automatic collection and detection device, which is used in measurement devices, analysis materials, material analysis by optical means, etc., can solve the difficulty in acquiring prior knowledge of fault characteristics, cannot meet the requirements of online monitoring, and cannot process blind source signals. Accuracy and other issues, to achieve the effect of accurately predicting the life of mechanical equipment, broad application prospects and significant value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

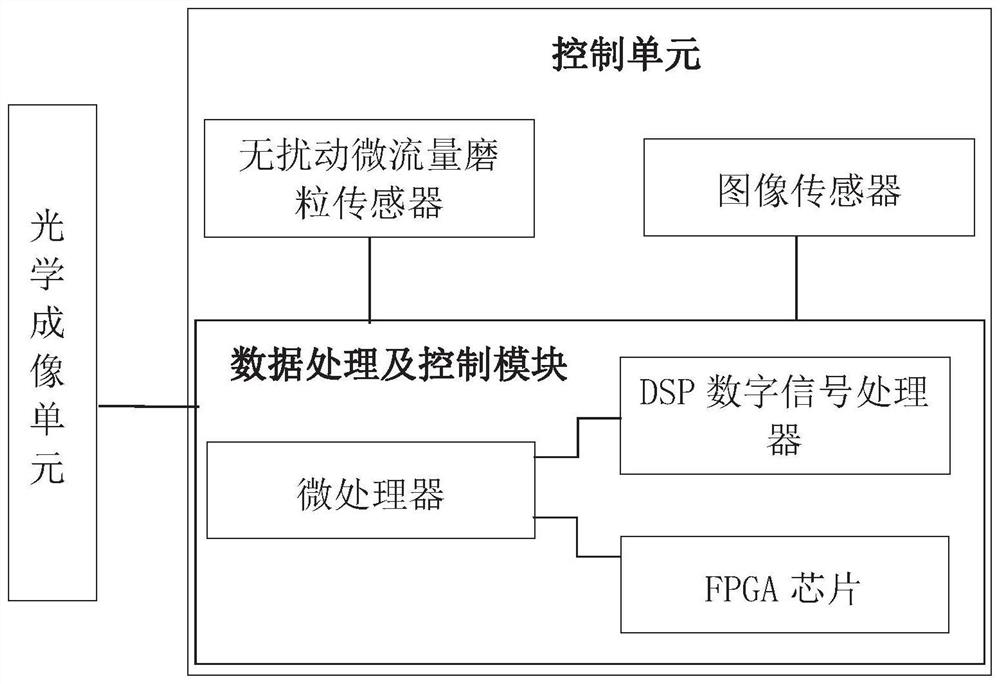

[0037] As mentioned above, the off-line ferrography technology has a large manual dependence and judgment lag in the analysis of equipment wear, resulting in low application efficiency and popularization rate. However, some advanced maintenance concepts, such as strain measurement, acoustic emission and vibration monitoring, have a priori knowledge of fault characteristics in the acquisition and prediction of wear state fault signals, which is difficult to obtain, the processing of blind source signals is inaccurate, and the early wear state is difficult to identify, etc. question.

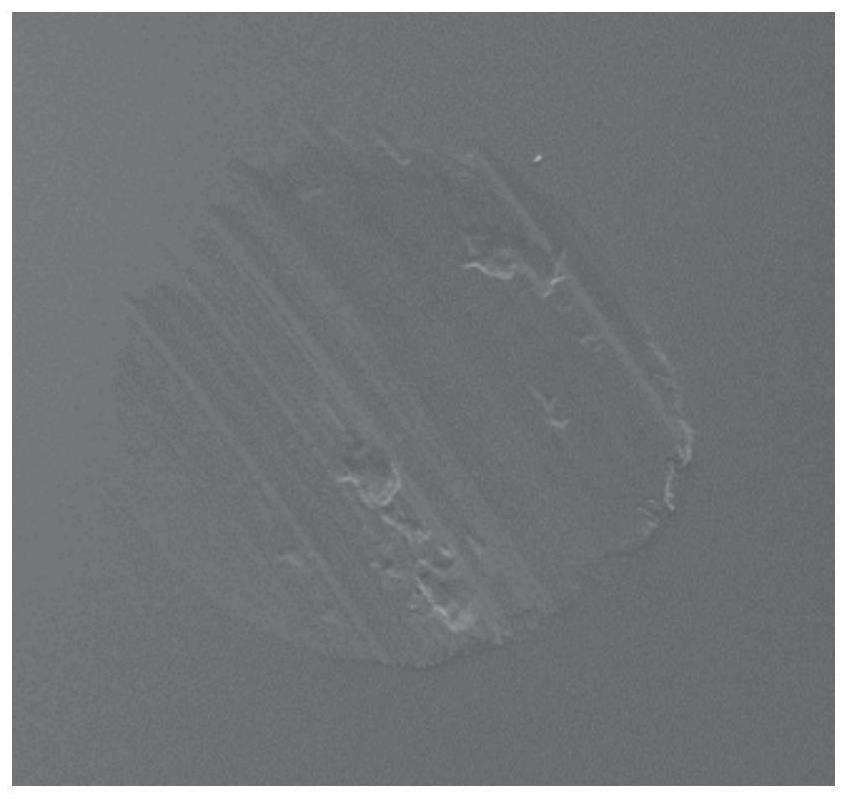

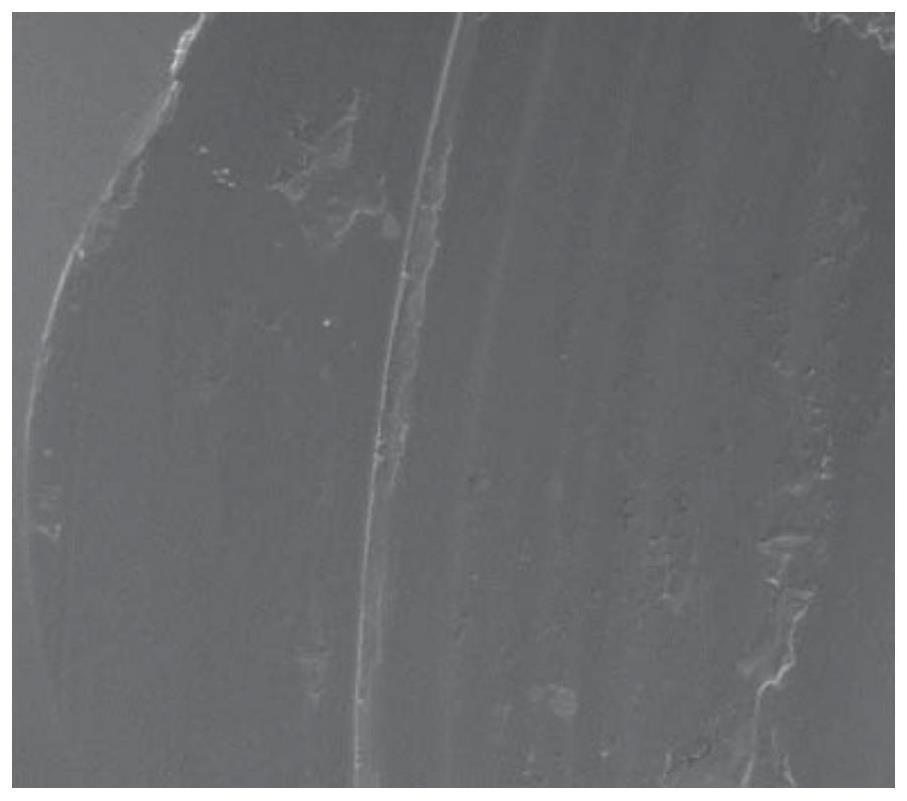

[0038] At the same time, the wear state is embodied in the geometric parameters, color parameters and texture parameters of the abrasive particles in the oil. These parameters are related to the judgment of wear type (abrasive wear, fatigue wear and oxidation wear) and wear severity (abrasive grain size, high temperature oxidation characteristic color). The wear state information obtained based o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com