Liquid oxygen pump water bath type vaporization device

A water-bath vaporizer and vaporization device technology, which is applied in direct contact heat exchangers, energy-saving heating/cooling, and climate sustainability, can solve problems such as potential safety hazards, large oxygen gaps, and poor ground operating environments, and avoid Potential safety hazards, promotion of absorption, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

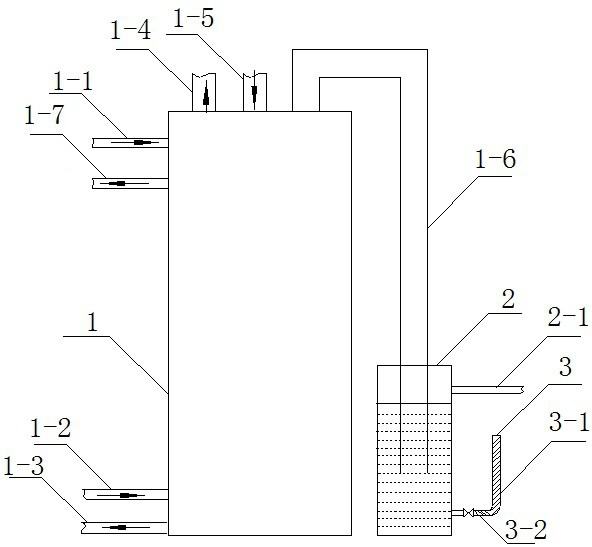

[0016] A liquid oxygen pump water bath vaporization device, such as figure 1 As shown, it includes a water-bath vaporizer 1, one side of the water-bath vaporizer 1 is sequentially provided with a circulating water pipe inlet 1-1, an overflow water pipe outlet 1-7, a liquid oxygen pipe inlet 1-2 and a circulating water pipe outlet 1-3, and the top of the water bath vaporizer 1 is provided with an oxygen pipe outlet 1-4 and a water vapor inlet 1-5, and the top of the water bath vaporizer 1 is also connected to the water seal tank 2 through the water vapor outlet pipe 1-6 connected, the water-sealed tank 2 is equipped with water, and the end of the water vapor outlet pipe 1-6 is sealed under water, and water is used to absorb the residual water vapor in heat exchange; the upper end of the water-sealed tank 2 is provided with an external connection pipe 2-1, water can be added to the water-sealed tank 2 through the external connection pipe 2-1, and excess water can be discharged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com