Heat-resistant and pressure-resistant solar reflective glass spike and preparation method thereof

A heat-resistant and pressure-resistant, solar energy technology, applied in the field of solar road studs, can solve the problems of affecting the use effect, short circuit of electronic components, corrosion of reflective sheets, etc., to reduce the probability of short circuit, enhance the pressure resistance, and protect electronic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

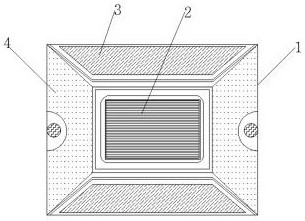

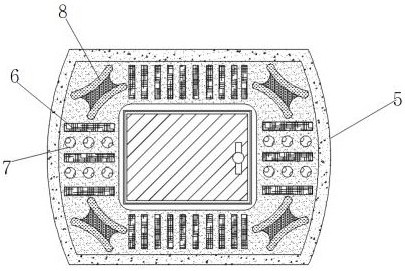

[0041] First aspect, such as Figure 1-6 As shown, the present invention provides a heat-resistant and pressure-resistant solar reflective glass road stud, including a housing 1, a transparent protective cover 2 is provided on the surface of the housing 1, a protective bottom 5 is provided on the bottom of the housing 1, and the housing 1 A reflective sheet 3 is fixedly installed on the side of the protective bottom 5, and a rectangular glue injection groove 6 is provided on the surface of the protective bottom 5, and a circular glue injection groove 7 is arranged on the side away from the rectangular glue injection groove 6. By setting the protective bottom 5 and the rectangular glue injection groove 6. During installation, fill the interior of the rectangular glue injection groove 6 and the circular glue injection groove 7 with glue until the surface of the glue is smooth, put the road stud at the designated position, and press firmly to make the road stud and the road surfac...

Embodiment 2

[0043] Such as Figure 1-6As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the bottom of the transparent protective cover 2 is provided with a solar panel 10, and the lower part away from the solar panel 10 is provided with an energy storage device 12 to protect the The top of the bottom 5 is fixedly installed with a reinforced waterproof bottom 11, and the top of the reinforced waterproof bottom 11 is provided with a reinforced support rod 13, and the solar panel 10 is fixedly installed on the top of the reinforced support rod 13. During the day, the solar panel 10 absorbs sunlight and turns the solar energy It is converted into electric energy and stored in the energy storage device 12. At night, the electric energy in the energy storage device 12 is automatically converted into light energy, controlled by a photoelectric switch, and the LED light 15 emits bright light to outline the road outline, induce the driver's sight,...

Embodiment 3

[0047] Second aspect, such as Figure 1-6 As shown, the present invention also provides a technical solution: a heat-resistant and pressure-resistant solar reflective glass road stud preparation method, the main steps of the heat-resistant and pressure-resistant solar reflective glass road stud preparation method are as follows:

[0048] Step 1: Material preparation;

[0049] Step 2: preparation process;

[0050] Step three: road installation.

[0051] Material preparation in Step 1 includes:

[0052] Electric hammer, disc ruler, batch knife, small glue bucket, chalk, generator, electric drill, glue mixer, epoxy resin A, B, cement.

[0053] Preparation process comprises the following steps in the step 2:

[0054] A1: The solar panel 10 uses PC bulletproof material to enhance the pressure resistance of the electronic part, and uses IC control to reduce the volume of the electronic circuit;

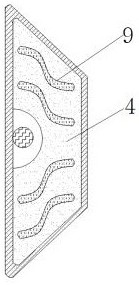

[0055] A2: By setting the arc-shaped anti-slip protrusion 9 to increase the fricti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com