Welding process for wave separating component of wave separator

A technology of welding process and wave splitter, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor sealing of wave splitting components, inaccurate signal wave splitting, and affecting the performance of wave splitters, etc., to achieve solid High accuracy, high splitting accuracy, and tight connection and sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

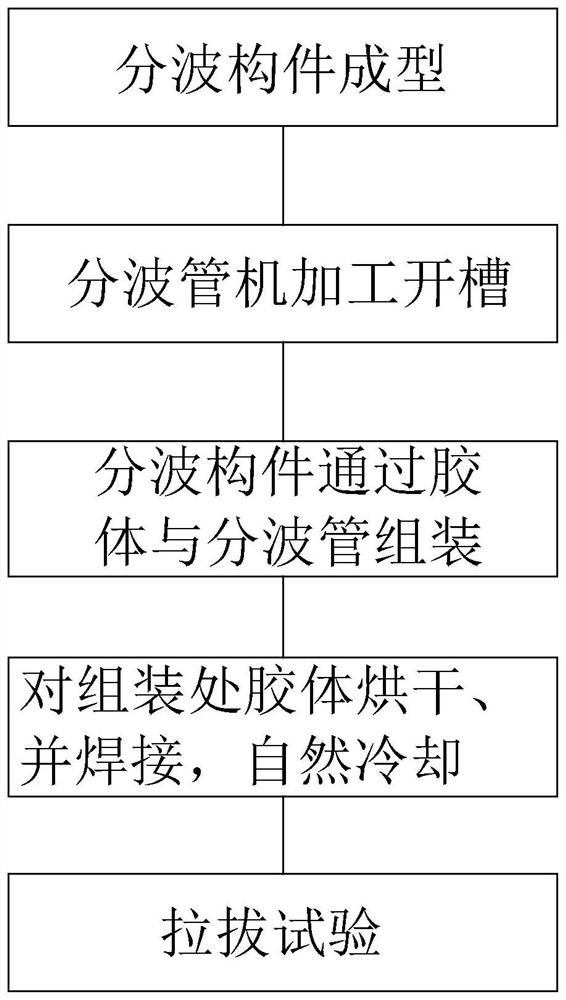

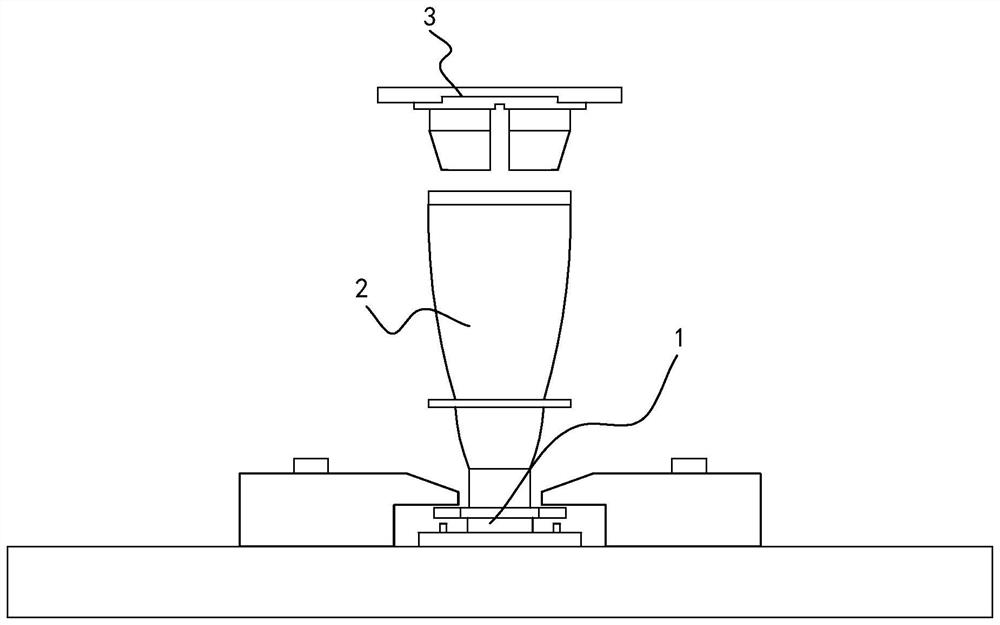

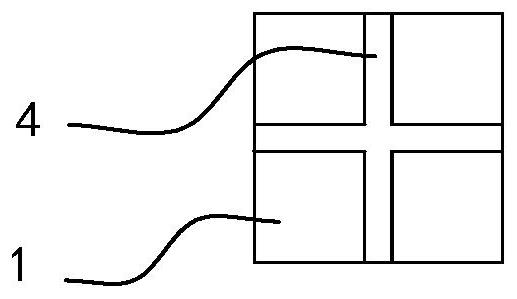

[0028] Such as Figures 1 to 5 As shown, the present invention is a welding process for a wave splitter component of a wave splitter, which includes the following processing steps: Step 1: Process the aluminum material through a wire cutting machine to obtain a cross-shaped wave split component 6, wherein the aluminum material used is 6061T6 type aluminum has high strength and hardness, good processing effect, good oxidation effect, no trachoma and pores, and good flatness. At the same time, the wave splitting member 6 processed above has no scratches or burrs, indicating that the maximum roughness is Ra1.6.

[0029] Step 2: Clamp the wave splitter 2 to the slotting machine, and open grooves 5 at the opening end, and there are four grooves 5, divide the wave splitter 2 into equal parts, and The inner wall of 2 extends inward, corresponding to the port of the above-mentioned cross-shaped wave splitting component 6 .

[0030] Step 3: Coat the inside of the groove 5 with glue, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com