Diaphragm filter press with crushed material slag hopper

A membrane filter press and slag hopper technology, applied in the direction of filtration separation, separation method, grain processing, etc., can solve the problems of easy damage to the auger, increase the cost of use, and cannot control the particle size of the filter cake, so as to reduce the subsequent crushing , Ease of delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment:

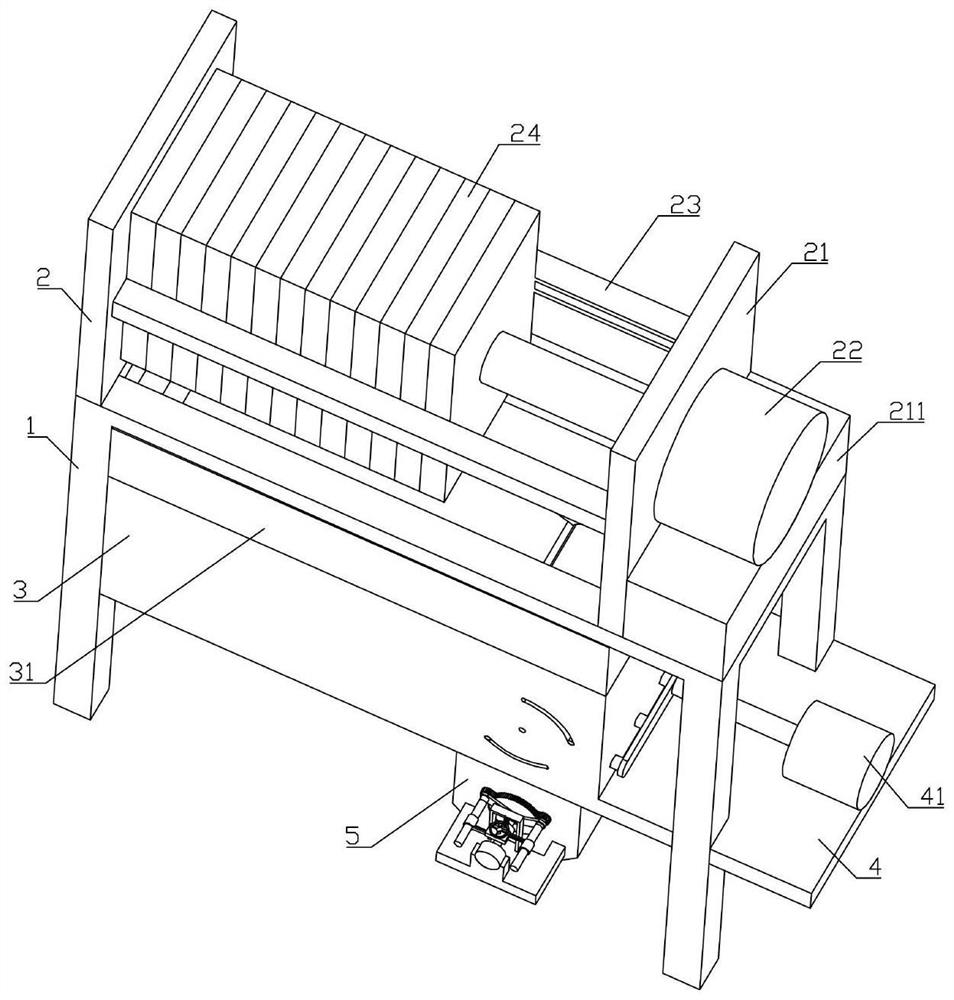

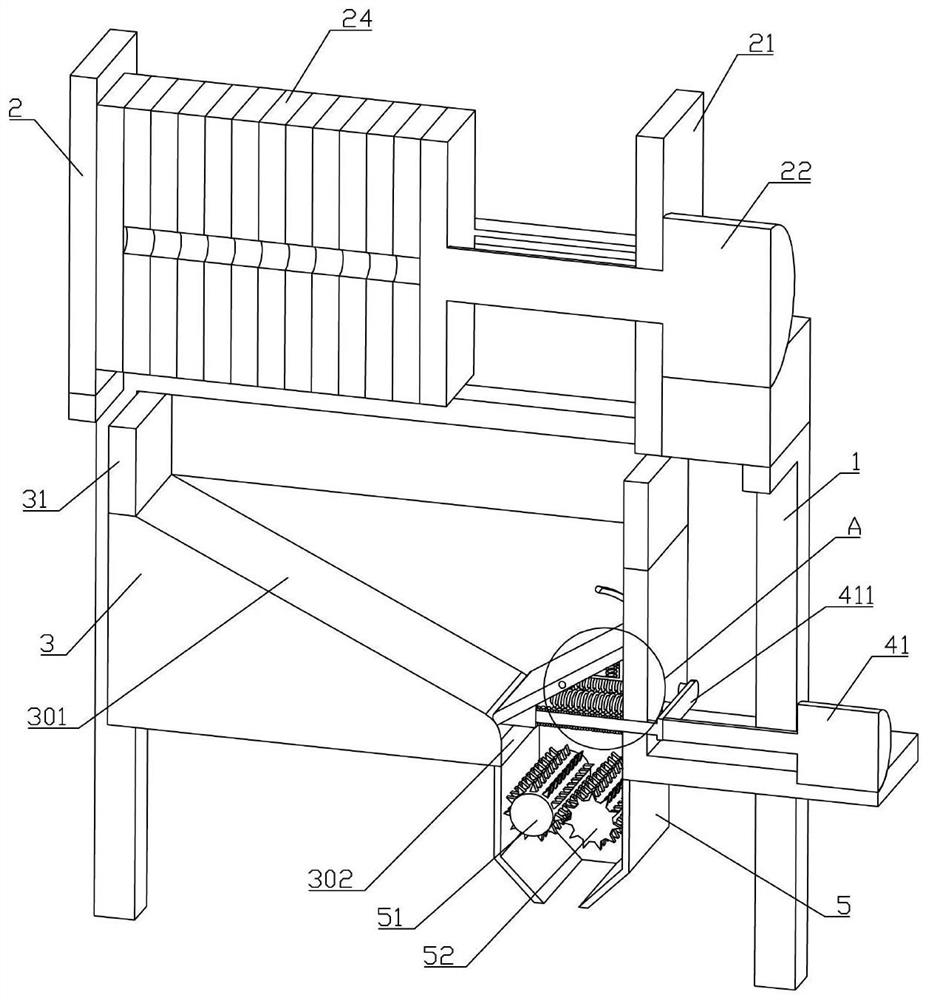

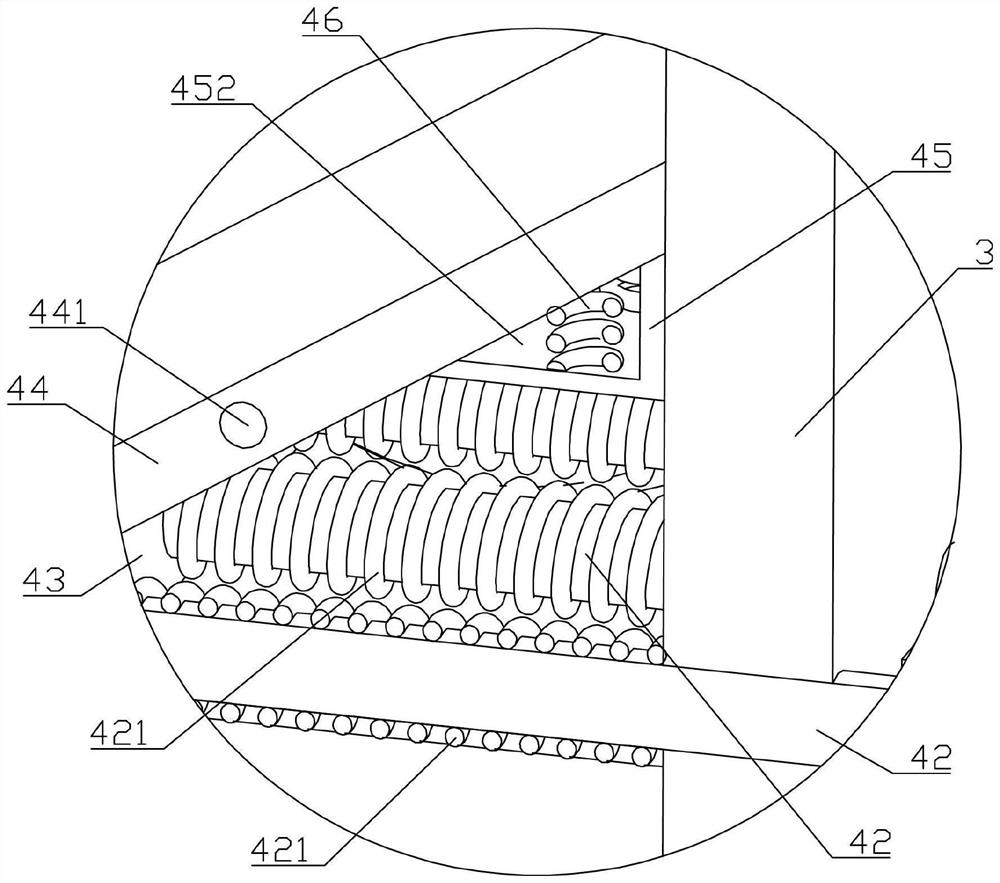

[0030] Such as Figure 1-8 As shown, a membrane filter press with a crushed slag hopper of the present invention includes a mounting frame 1, and a first baffle plate 2 and a second baffle plate 21 are respectively fixedly installed on both sides of the mounting frame 1, and the first baffle plate 2 and the second baffle plate 21 are fixedly installed with two main beams 23, and between the two main beams 23 are installed a plurality of filter plates 24, and one side of the second baffle plate 21 is fixedly installed with a first mounting base 211, A hydraulic cylinder 22 is fixedly installed on the first installation seat 211, and the output shaft of the hydraulic cylinder 22 is connected with the first filter plate 24 close to the second baffle plate 21. Through the work of the hydraulic cylinder 22, a plurality of filter plates 24 can be squeeze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com