Technological method for mounting floating type rigid magnet yoke

An installation method and a floating technology, which is applied in the field of floating rigid yoke installation, can solve the problems of inability to achieve positioning effect and inter-segment displacement, and achieve the effects of high yoke assembly efficiency, fast positioning, and cost savings for installation tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

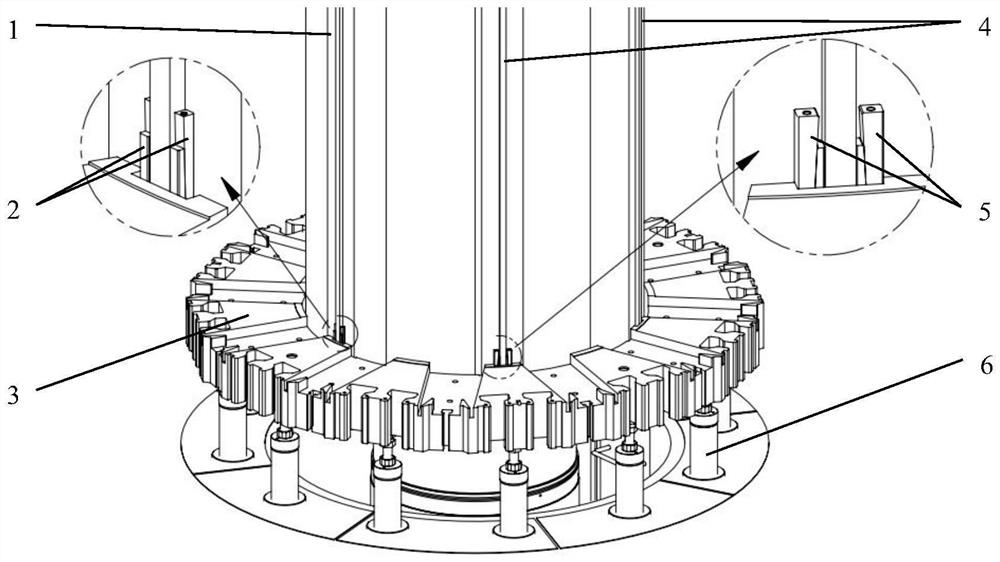

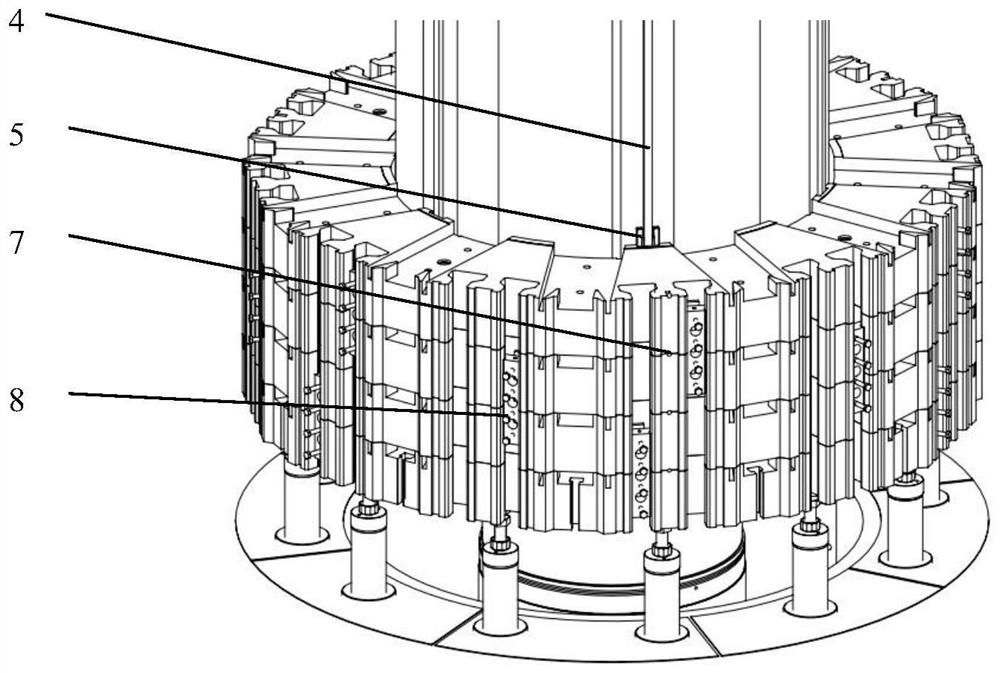

[0039] like figure 1 , figure 2 As shown, the present invention provides a process method for installing a floating rigid yoke, which can complete the installation of a floating rigid yoke with high efficiency and high quality. The technical solution of the present invention is:

[0040] 1) Check the verticality of the main shaft by electric measuring method, and adjust it to and level to 0.02mm / M, check the height deviation of the hook height of the main vertical rib 1 with a level gauge, and it should not be greater than 0.15mm, otherwise use a file to repair the hook mating surface;

[0041] 2) Install the rotor measuring circle frame and adjust it to the rotation level of 0.02mm / M, and the concentricity with the main shaft or rotor bracket is 0.03mm;

[0042] 3) Hoist the first yoke section 3. During the hoisting process, ensure that the radial gap between the yoke section 3 and the main rib convex key 4 is uniform. Use a steel tape to check that the height difference be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com