Stator and rotor horizontal assembling device and assembling method of turbine power generation equipment

A turbine power generation and rotor technology, applied in the manufacture of stator/rotor body, etc., can solve the problems of unsuitable turbine power generation devices, and achieve the effects of easy assembly accuracy, high precision, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

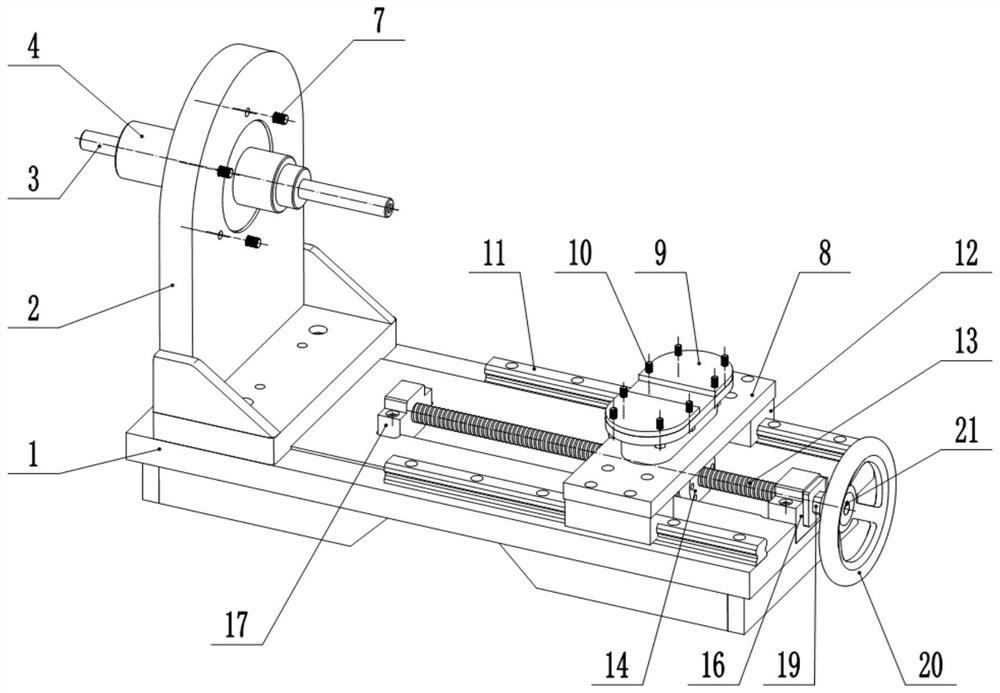

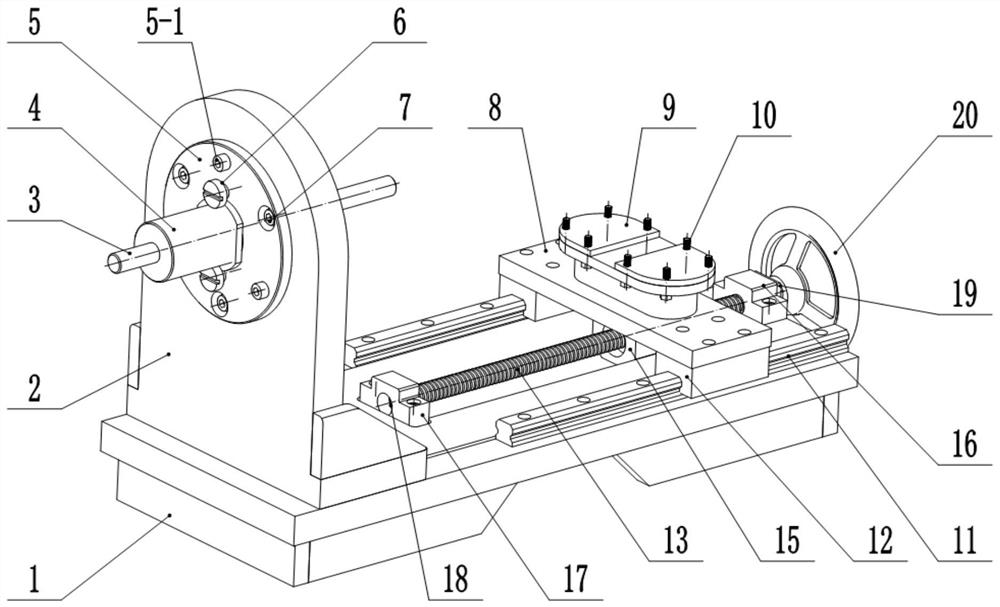

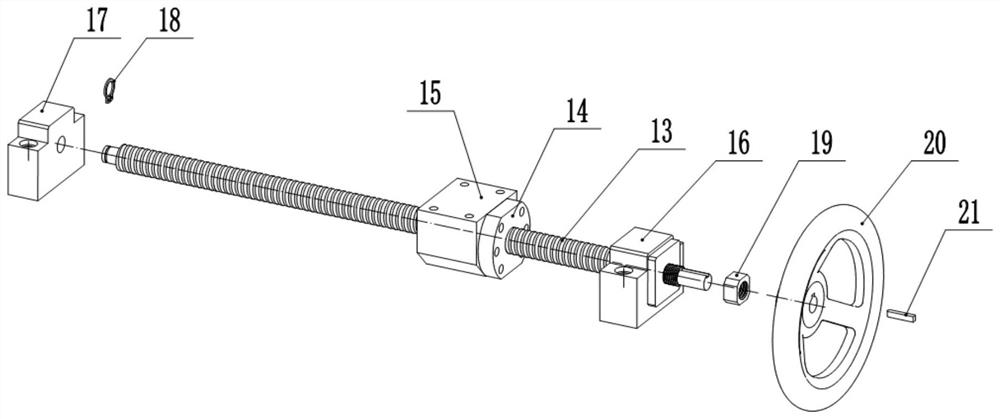

[0045] Embodiment 1: A horizontal stator and rotor assembly device for turbine power generation equipment in this embodiment includes a platform base 1, a casing bent plate bracket 2, a guide shaft rod 3, a positioning guide sleeve 4, a shaft sleeve fixed Center end cover 5, end cover fixing screw 5-1, limit shoulder screw 6, casing fixing screw 7, turbine housing sliding bracket 8, turbine housing adjusting backing plate 9, turbine housing fixing screw 10, a Secondary linear guide rail 11, one pair of sliders 12, ball screw 13, screw nut 14, screw nut seat 15, fixed end seat 16, support end seat 17, retaining ring 18, nut 19, hand wheel 20 and flat key twenty one;

[0046] The casing bent plate bracket 2 is used to install the stator and the casing assembly, the casing bent plate bracket 2 is fixed on the left end of the platform base 1, and a pair of linear guide rails 11 are installed on the axis parallel to the stator and rotor of the turbine power generation equipment On...

Embodiment 2

[0048] Embodiment 2: A method for assembling the stator and rotor of a turbine power generation equipment in this embodiment includes:

[0049] Before assembling, place the sliding bracket 8 of the turbine casing on the rightmost end of the linear guide rail 11, and use the connection hole at the outer end of the turbine generator casing to align the outer circle of the front end of the centering shaft with the positioning guide sleeve 4 to correspond to the turbine generator casing. The inner hole cooperates with the centering; the center is limited, and the stator and the casing assembly are fixed on the casing bending plate bracket 2 with the casing fixing screw 7, and the positioning guide bushing 4 is rotated so that the shoulder of the bushing is stuck in the limit position In the limit shoulder of the shoulder screw 6, it is ensured that when the guide shaft rod 3 moves axially left and right in the center hole of the positioning guide sleeve 4, the positioning guide sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com