Device for LED wafer manufacturing process

A wafer and process technology, applied in the field of LED wafer process equipment, can solve problems such as machine failure, large pressure ring size of the carrier plate, and inability to press the carrier plate, etc., to ensure wafer processing yield, The effect of reducing the area of the slot and increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

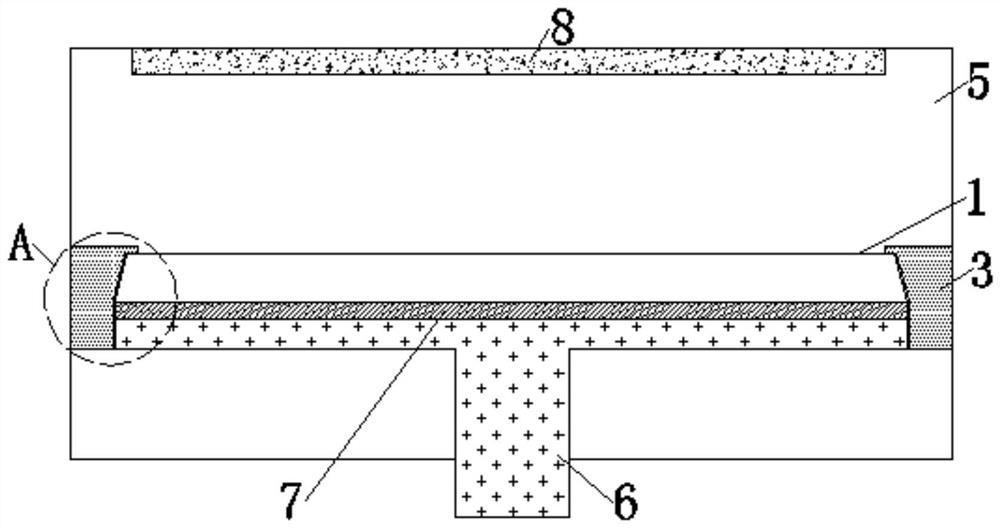

[0043] A device for LED wafer manufacturing process provided by this embodiment, such as image 3 , Figure 4 shown, including:

[0044] Carrier 1, the carrier 1 is provided with a wafer placement surface, the side 2 of the carrier is an inclined surface, and the side 2 of the carrier forms a carrier inclination angle θ1 with the wafer placement surface;

[0045] The pressing ring 3, the pressing ring 3 includes a pressing part 31 and a positioning angle θ2 of the pressing ring;

[0046] During the LED wafer manufacturing process, the wafer Y is placed on the wafer placement surface, the pressure ring 3 is used to fix the carrier plate 1, the pressure ring positioning angle θ2 is used to position the carrier plate inclination angle θ1, and the pressing part 31 is used to press the carrier plate Edge 4, wherein the shape and angle of the positioning angle θ2 of the pressure ring matches the inclination angle θ1 of the carrier plate.

[0047] It should be noted that during th...

Embodiment 2

[0050] Such as Figure 5 , Figure 6 As shown, a device for LED wafer manufacturing process differs from the first embodiment above in that the wafer placement surface is provided with wafer placement grooves 9 close to each other; the wafer placement groove 9 includes a central wafer placement Slot 91 and several peripheral wafer placement slots 92; the central wafer placement slot 91 is located at the center of the wafer placement surface, and each peripheral wafer placement slot 92 is set around the center wafer placement slot 91.

[0051] Optionally, in this embodiment, the bottom surfaces of the wafer placement slots 9 are at the same level.

[0052] Optionally, in this embodiment, the width W1 of the side surface of the carrier plate in the vertical direction ranges from 1 mm to 3 mm, inclusive.

[0053] Optionally, in this embodiment, the edge width W2 of the carrier plate ranges from 2 mm to 10 mm, including the endpoints.

[0054] Optionally, in this embodiment, th...

Embodiment 3

[0058] Such as Figure 7 As shown, a device for LED wafer manufacturing process differs from the second embodiment above in that the raised portion between the central wafer placement groove 91 and the peripheral wafer placement groove 92 is the Y region 10, and the peripheral wafer The raised portion between the circular placement groove 92 and the side surface 2 of the carrier plate is the Z zone 11; the horizontal height of the bottom surface of the central wafer placement groove is H1, the horizontal height of the Y zone is H2, the horizontal height of the Z zone is H3, and the wafer height is H4 , then H1<H2≤H1+H4, and H2<H3.

[0059] It should be noted that, in this embodiment, the edge 4 of the carrier disk (not shown in the figure) is within the range of the Z zone 11 .

[0060] Optionally, in this embodiment, the level difference between H2 and H1 ranges from 20 um to 650 um, including the endpoint values.

[0061] Optionally, in this embodiment, pick-and-place open...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Edge width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com