Non-vision-field single-pixel imaging system and glossy surface defect detection method

An imaging system, single-pixel technology, applied in image analysis, image data processing, instruments, etc., can solve the problems of affecting other areas of inspection, uneven light intensity distribution, etc., to balance the reflected light intensity, suppress highlights, and overcome the phenomenon of specular reflection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

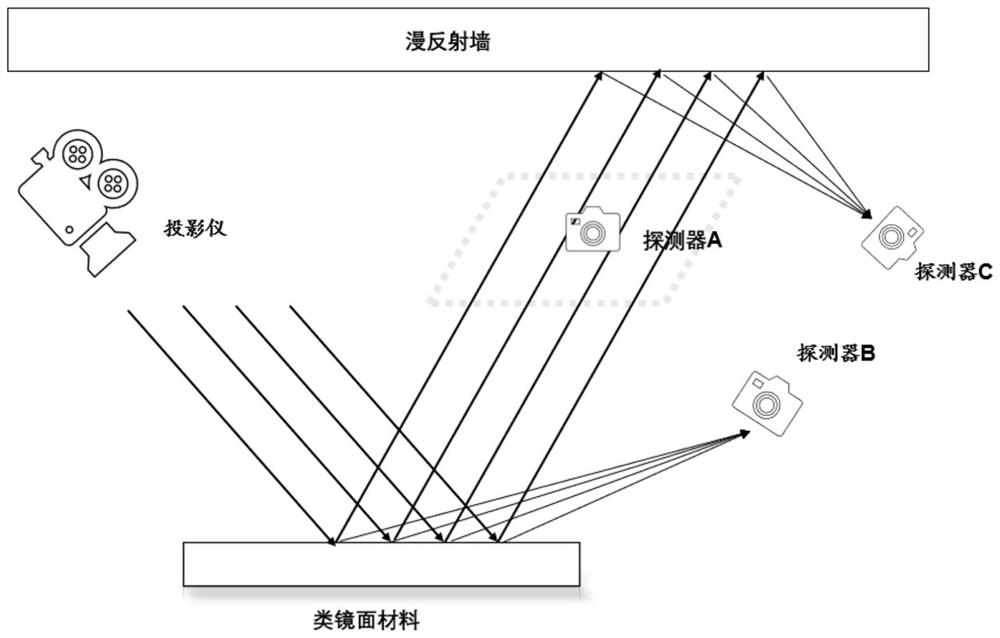

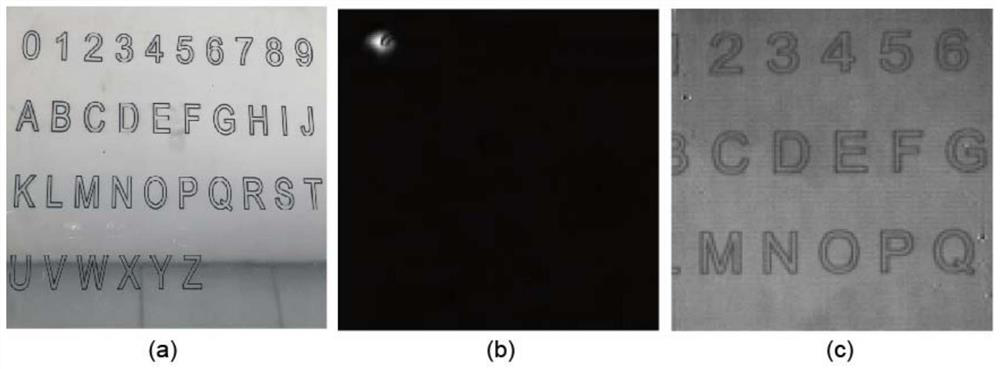

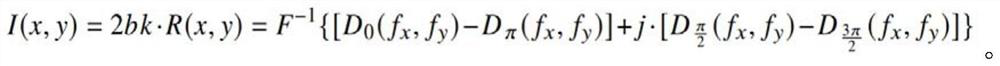

[0033] Such as figure 1 As shown, the single-pixel direct imaging based on detector A is to use the spatial light modulator to generate the Fourier base pattern to illuminate the object and use the single-pixel detector to detect the light field intensity from the object, so as to realize the Fourier The leaf space is scanned to obtain the Fourier spectrum of the object image, and then the inverse Fourier transform is performed on the obtained Fourier spectrum, and finally the single-pixel two-dimensional imaging method is realized.

[0034] Howeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com