Factory hazard source identification method based on BIM

An identification method and technology of hazard sources, applied in the field of hazard source identification, can solve problems such as safety accidents and the inability of new hazard source staff to make reasonable judgments, so as to achieve personal safety protection, prevent danger from occurring, and enhance enthusiasm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

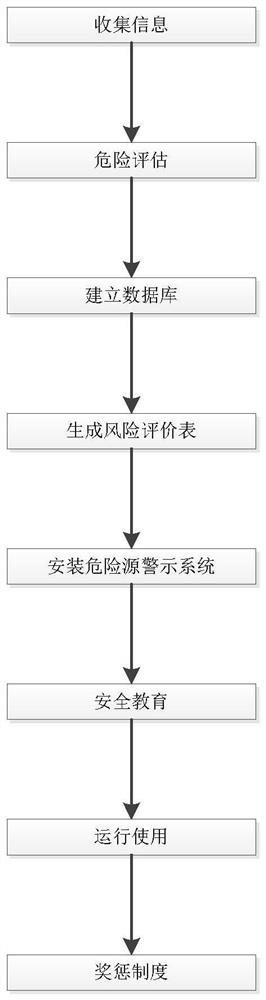

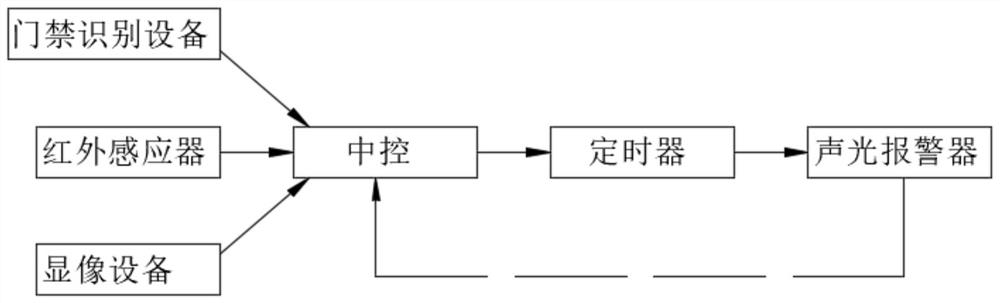

[0037] see Figure 1~3 , in an embodiment of the present invention, a method for identifying hazards in a factory based on BIM includes the following steps:

[0038] A. Collect information: Conduct field inspections inside the factory, collect information on the various factories and surrounding buildings, including geographical location, civil engineering structure, traffic roads in the factory, etc., and arrange questionnaires simultaneously, according to the distribution of staff and types of operations Collect potential sources of danger, check historical accident records, and analyze accident causes;

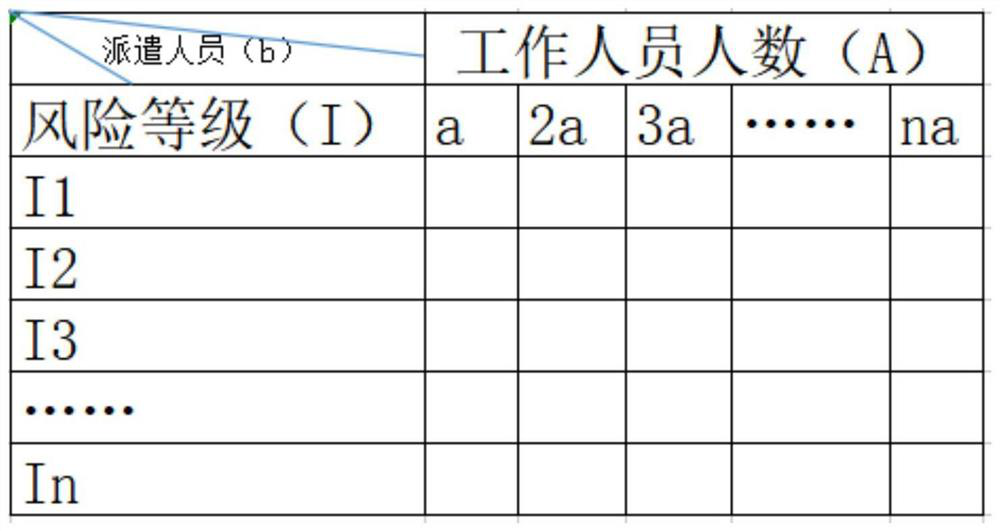

[0039] B. Safety risk assessment, and generate a risk assessment table: Safety risk assessment includes identifying the hazards of safety accidents, assessing the risks of hazards, and the measures and management of risk control;

[0040] C. Establish a database, classify and build a database according to different information, and supplement and build a database according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com