Operation method for cooperatively carrying same goods by multiple AGVs (Automatic Guided Vehicles) and storage medium

One kind of goods, the same technology, applied in the field of operation methods and storage media for multiple AGVs to jointly carry the same goods, can solve problems such as unsatisfactory, and achieve the effect of ensuring safety, ensuring synchronization and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

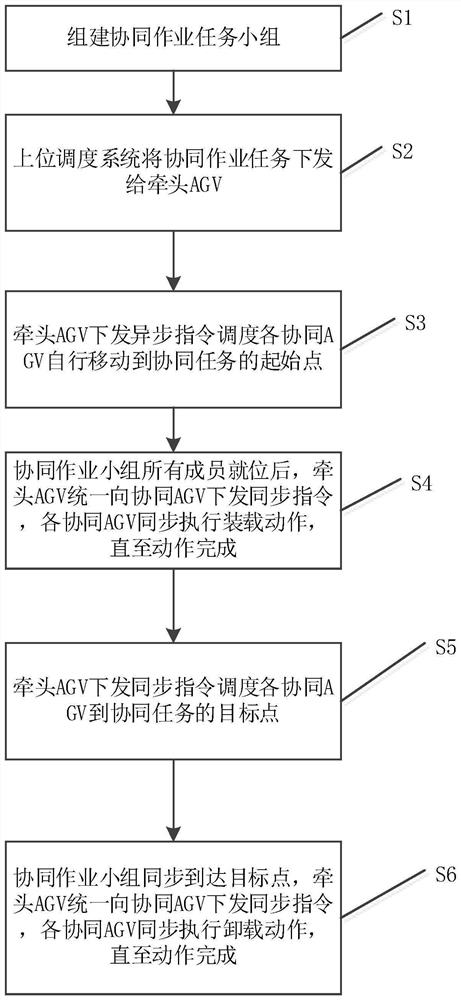

[0038] Such as figure 1 As shown, the present invention provides a method of working with multiple AGVs to handle the same cargo, including the following steps:

[0039] Step S1: Set the collaborative job task team; specifically:

[0040] The upper scheduling system issues a bidding notification with a collaborative task attribute in a task bidding. The upper scheduling system specifies the number N of the Joch Job AGV member N, which is the NAT-based number of N platforms required to match the number of the number of AGVs, and is specified by the upper scheduling system. AGV and collaborative AGV, the collaborative job team is completed by the upper scheduling system; the upper system communicates with each AGV; or:

[0041] The upper scheduling system issued a bidding notification with a collaborative task attribute in a task bidding, the upper scheduling system specifies the number of employees N, which is taken by the AGV of the winning bid, and the lead AGV is responsible for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com