Continuous casting slab quality prediction method based on extreme learning machine

An extreme learning machine and quality prediction technology, applied in the field of iron and steel metallurgy, can solve problems such as unfavorable high-efficiency production of high-quality steel in iron and steel enterprises, quality judgment of continuous casting slabs in iron and steel enterprises, and falling into local optimal values, so as to improve classification accuracy and The effects of computing speed, fast training speed, and long training time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

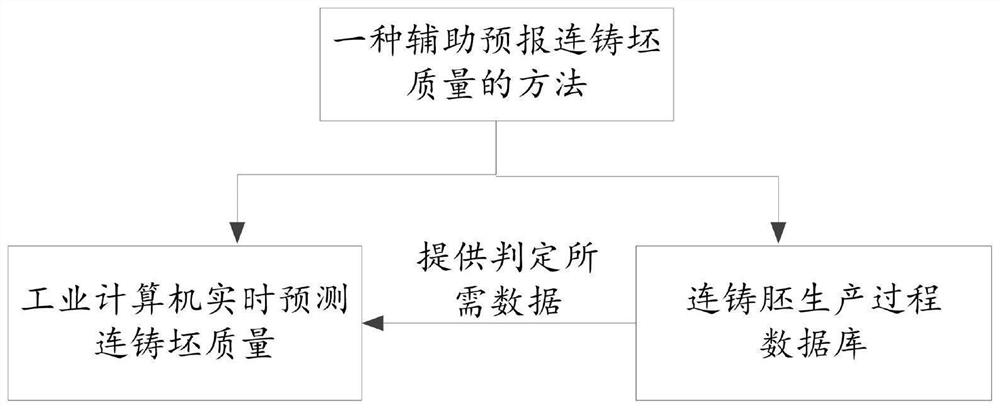

[0027] The invention provides a continuous casting slab quality prediction method based on extreme learning machine, such as figure 1 Shown is a schematic diagram of the method.

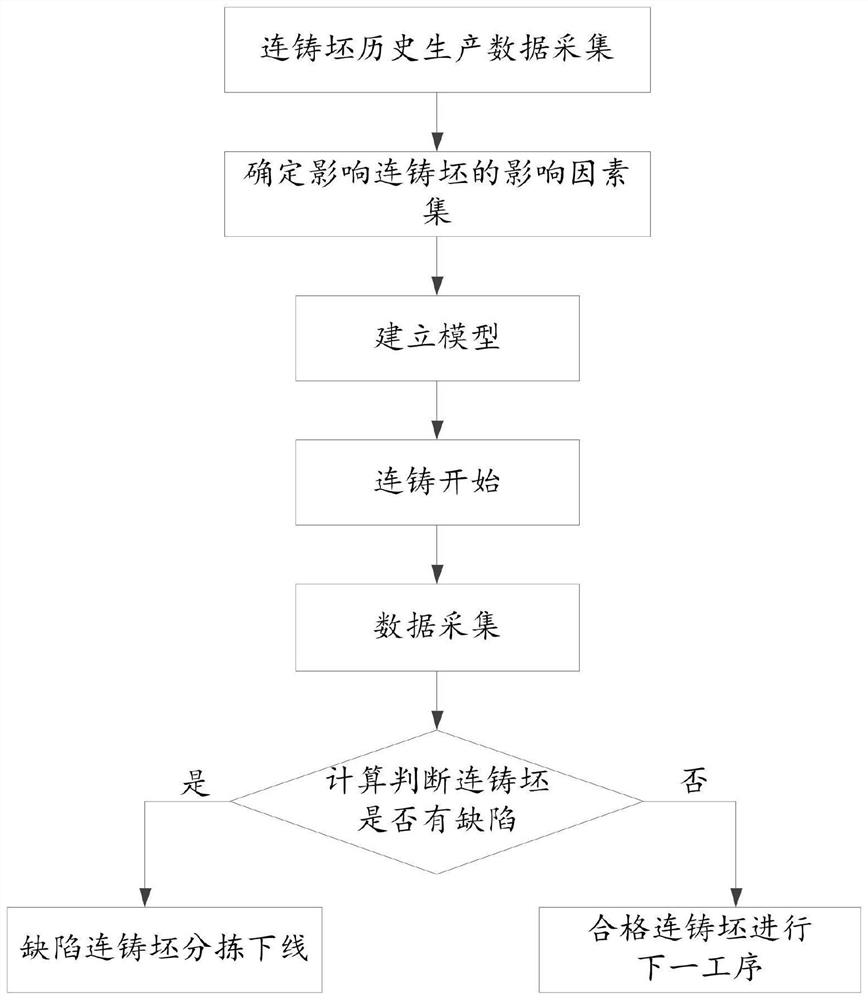

[0028] Such as figure 2 As shown, the specific steps of the method are as follows:

[0029] (1) Selection of input variables of extreme learning machine: According to the factors affecting the quality of continuous casting slab and the defects of continuous casting slab, use the Pearson correlation coefficient to conduct correlation analysis to find the influencing factors affecting the quality of continuous casting slab;

[0030] (2) Collect the data of factors affecting the quality of continuous casting slabs, and preprocess these data, determine the number of input nodes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com