Intelligent production progress monitoring system for textile mill production line

A technology of production progress and monitoring system, applied in the field of textile production, can solve problems such as unreliability, heavy workload, and inconvenient retrieval, and achieve the effect of avoiding detection misjudgments and improving accurate detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

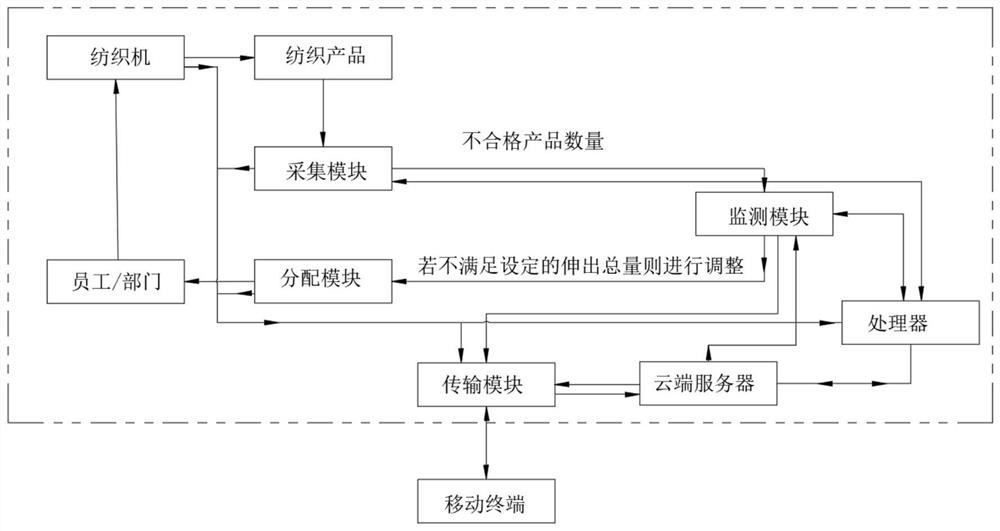

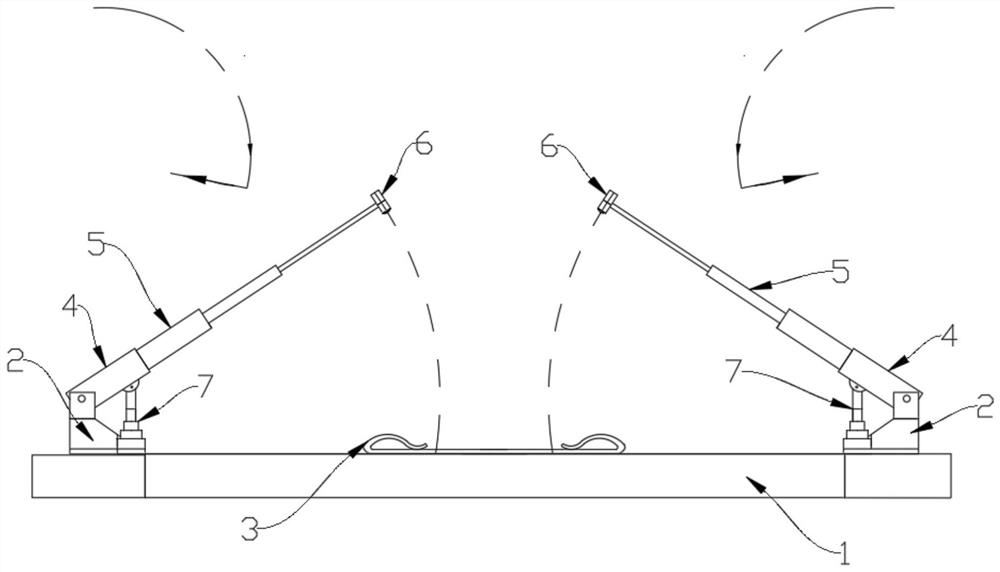

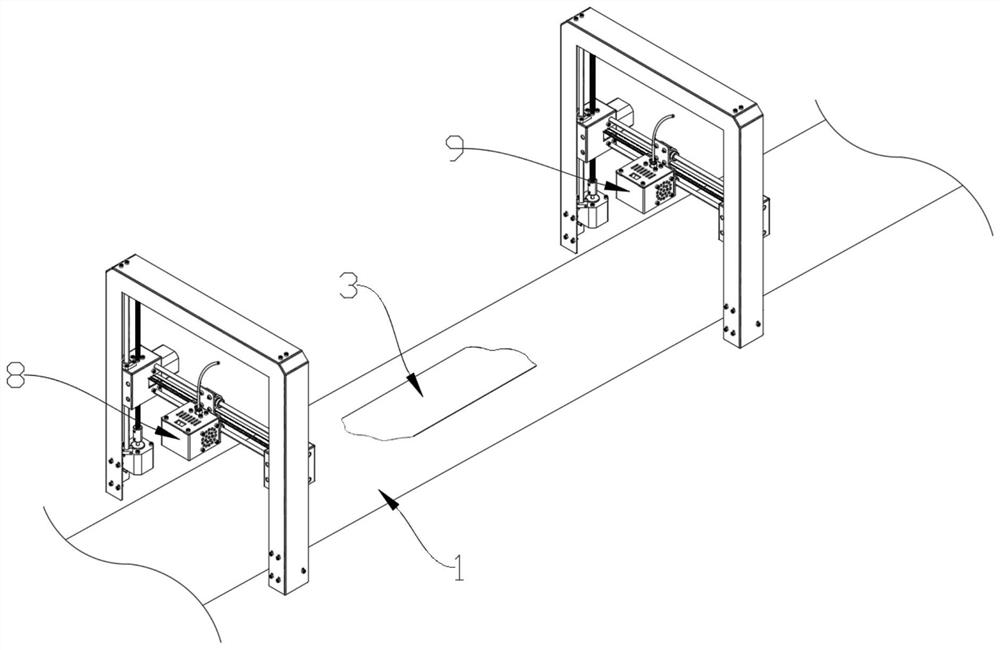

[0053] according to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present embodiment provides an intelligent production progress monitoring system for a textile factory production line, including a distribution module, an acquisition module, a monitoring module, a transmission module, a cloud server and a processor,

[0054] The processor is respectively connected to the cloud server, the distribution module, the collection module, the monitoring module and the transmission module, and the distribution module, the collection module, the monitoring module and the transmission module are controlled under the centralized control of the processor. precise control;

[0055] The cloud server is respectively connected with the distribution module, the collection module, the monitoring module and the transmission module, and receives the real-time data fed back by the distribution module, the collection module, the monitoring module and the transmission module. ...

Embodiment 2

[0104] This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements on the basis thereof, according to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , further comprising receiving an access request from the mobile terminal to the cloud server from the verification unit, the access request including metadata corresponding to the mobile terminal and the personal identification credential of the device holder; by determining whether the metadata is in Verify that the identification credential is valid within one or more predetermined parameters corresponding to the account;

[0105] The verification unit also includes an identity authorization controller and a storage library, the identity authorization controller is used to receive the mobile terminal's access request to the node of the cloud server; the storage library is used to store a plurality of digital identity certification do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com