Optical fiber introduction device and optical fiber introduction method

A technology of introducing devices and optical fibers, which is applied in the field of vacuum chambers, can solve problems such as affecting use, low airtightness, and leakage of workpiece table chambers, and achieves the effects of easy installation, high integration, and vacuum airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

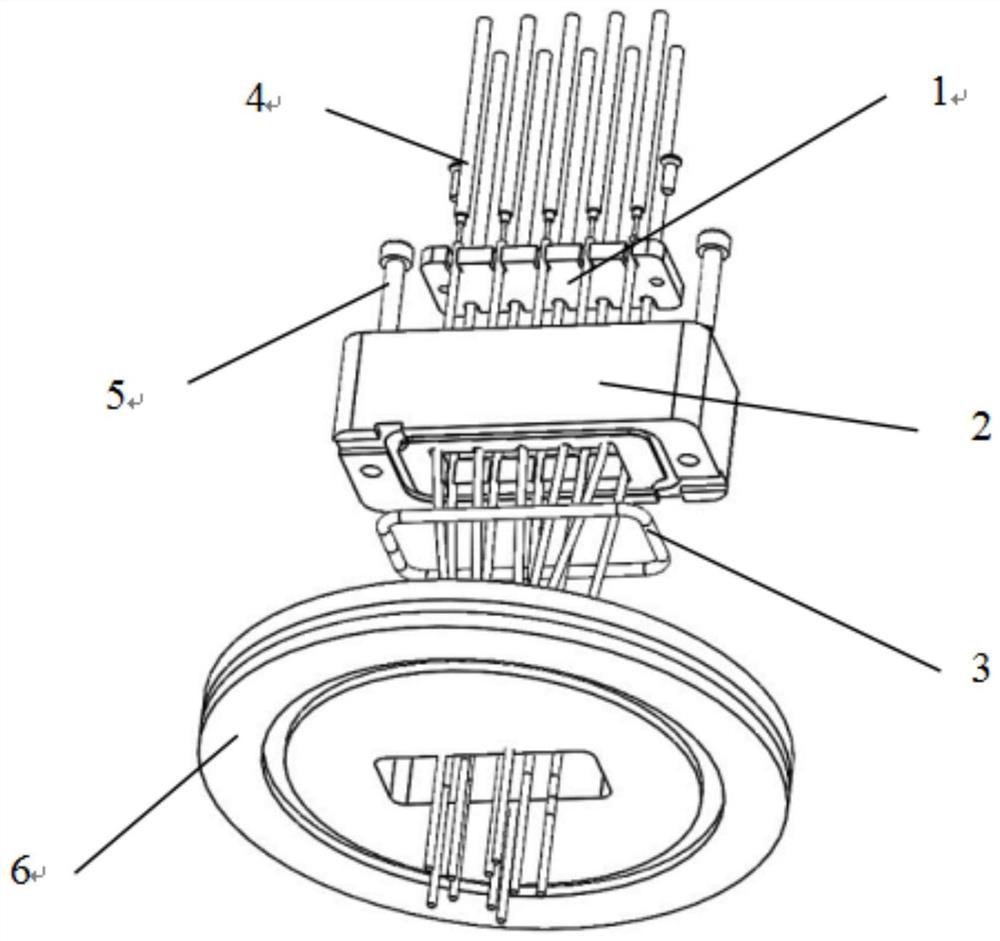

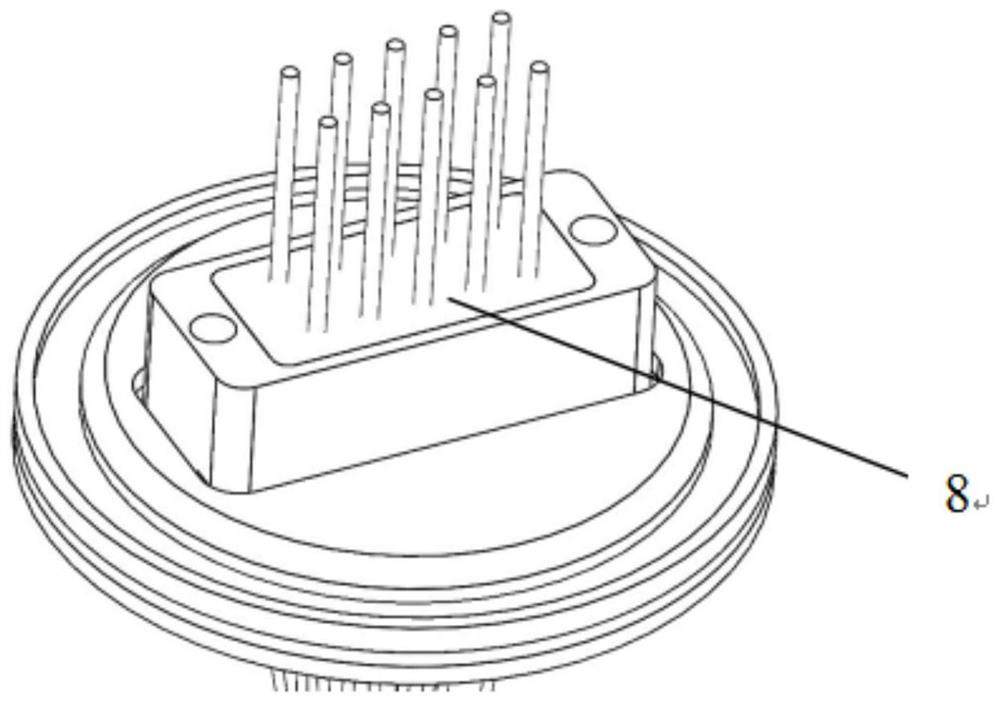

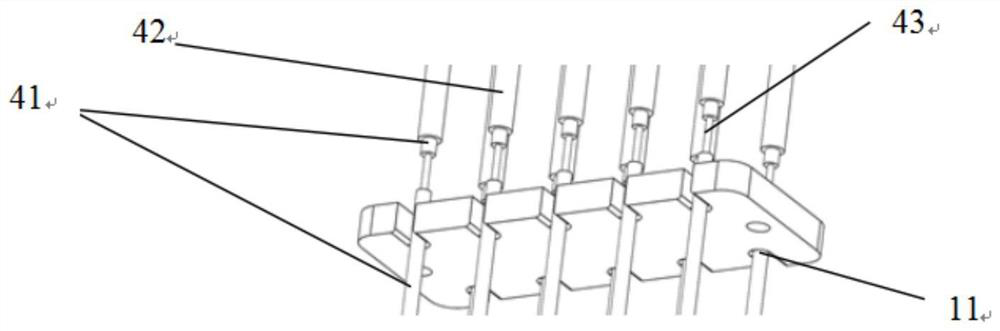

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an optical fiber introduction device according to an embodiment of the present invention includes a blocking piece 1, a glue filling seat 2, a vacuum potting glue layer, and a sealing and bonding glue layer 8. The metal material is processed, the block 1 is thin sheet, the edge of the block 1 is provided with a plurality of first grooves 11 for the optical fiber 4 to pass through, the glue filling seat 2 is a hollow body surrounded by side walls, A central hole 21 is formed in the center of the glue filling seat 2, and the inner wall of the glue filling seat 2 is provided with a first annular boss 24 and a second annular boss 27, and the width of the first annular boss 24 is greater than that of the second annular boss. The width of the table 27, the edge of the first annular boss 24 close to the central hole 21 is provided with a plurality of second grooves 22, the second grooves 22 are used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com