Detection method for internal atmosphere of vacuum packaging device, airtight container and detection equipment

A technology of vacuum encapsulation and internal atmosphere, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of difficult detection and low total amount of internal atmosphere, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

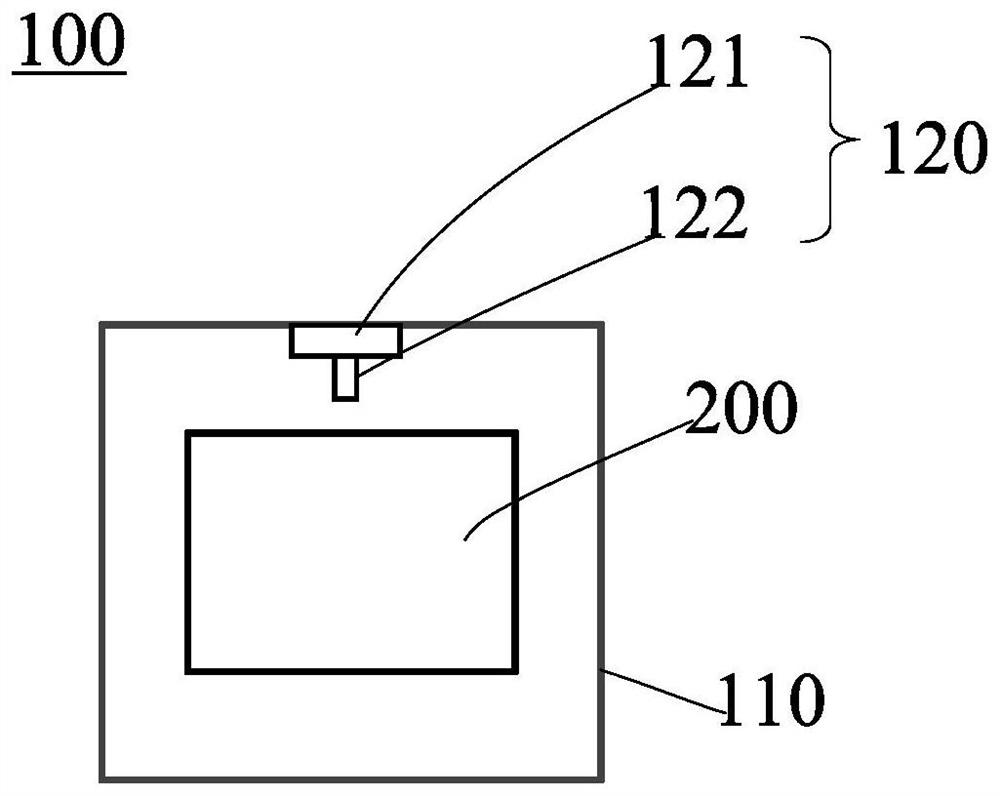

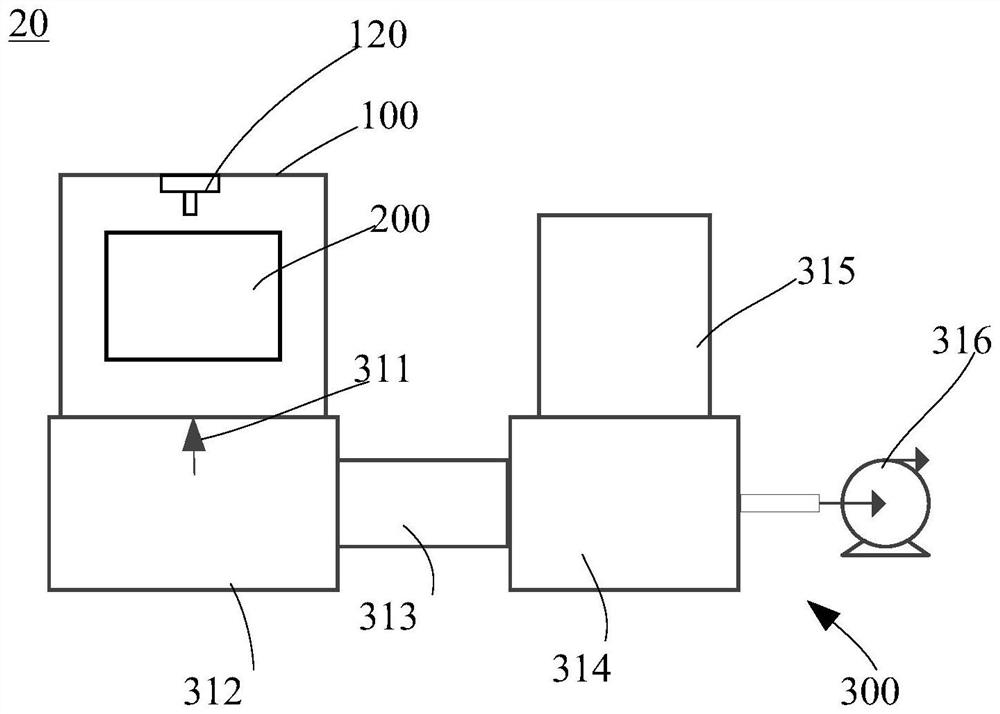

[0073] This embodiment provides an airtight container, including a pumored cavity, and a damaged mechanism.

[0074] The airtight chamber includes a cavity body and a sealing cover. The cavity body is provided with an inlet, and the vacuum package device to be tested is loaded into the cavity body. The sealing cover is used to cover the load in an inlet to form a sealed state in the airtight cavity.

[0075] The damage mechanism includes a drive member and a force of the force. The drive member is connected to the cavity wall of the airtight cavity. The shroud member is connected to the drive member. The force of the force is a piercing needle, and the drive member is used to drive the urging member to puncture the vacuum package device and destroy its housing.

Embodiment 2

[0077] This embodiment provides an airtight container, including an airtight cavity, a constant mechanism, and a damaged mechanism.

[0078] The airtight chamber includes a cavity body and a sealing cover. The cavity body is provided with an inlet, and the vacuum package device to be tested is loaded into the cavity body. The sealing cover is used to cover the load in an inlet to form a sealed state in the airtight cavity.

[0079] The limiting mechanism is a clamping member, which is disposed on the inner wall of the airtight cavity for clamping the vacuum package device in the airtight cavity, and performs a limit.

[0080] The damage mechanism includes a drive member and a force of the force. The drive member is connected to the cavity wall of the airtight cavity. The shroud member is connected to the drive member. The shroud is used to cut the knife, and the drive member is used to drive the urging member to cut the vacuum package device, and destroy its housing.

Embodiment 3

[0082] This embodiment provides an airtight container, including an airtight cavity, a constant mechanism, and a damaged mechanism.

[0083] The airtight chamber includes a cavity body and a sealing cover. The cavity body is provided with an inlet, and the vacuum package device to be tested is loaded into the cavity body. The sealing cover is used to cover the load in an inlet to form a sealed state in the airtight cavity.

[0084] The limiting mechanism is a bond, disposed on the inner wall of the airtight cavity, and is used to adhere the vacuum package device in the airtight cavity to limit it.

[0085] The damage mechanism includes a drive member and a force of the force. The drive member is connected to the cavity wall of the airtight cavity. The shroud member is connected to the drive member. The force of the shock hammer is used to drive the shock of the vacuum packaging device to drive the urging member.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com