AOI indentation detection system and method

A detection system and indentation technology, applied in the direction of measuring devices, optical testing flaws/defects, and material analysis through optical means, can solve problems such as difficult to accurately find out products, and achieve excellent interference effects and good user observation experience , the effect of solving technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

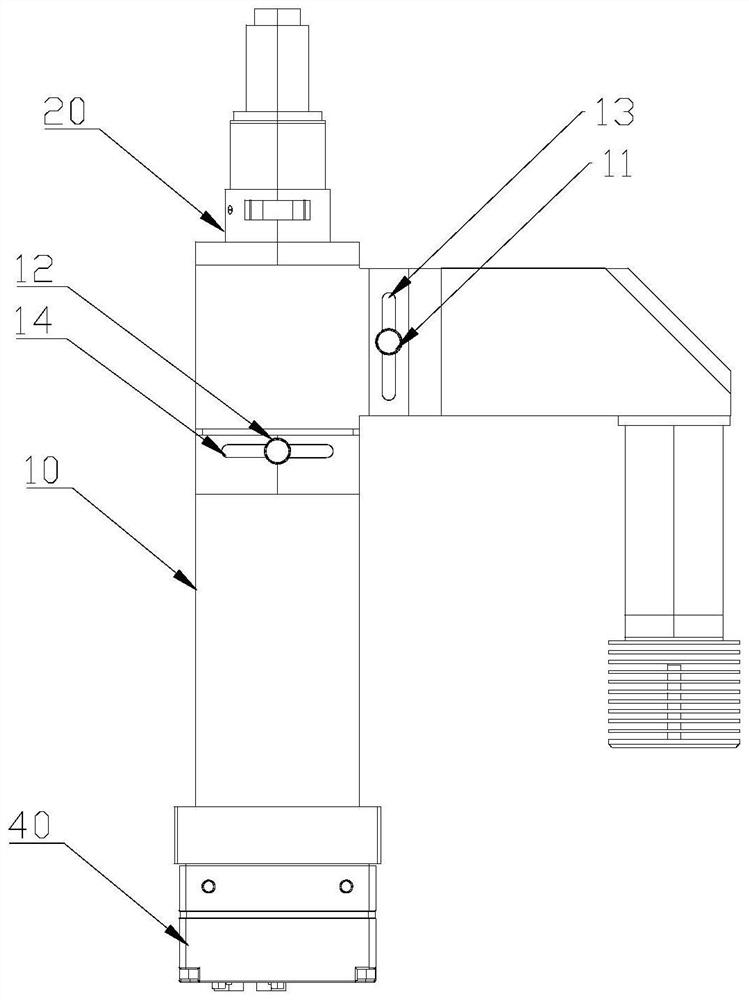

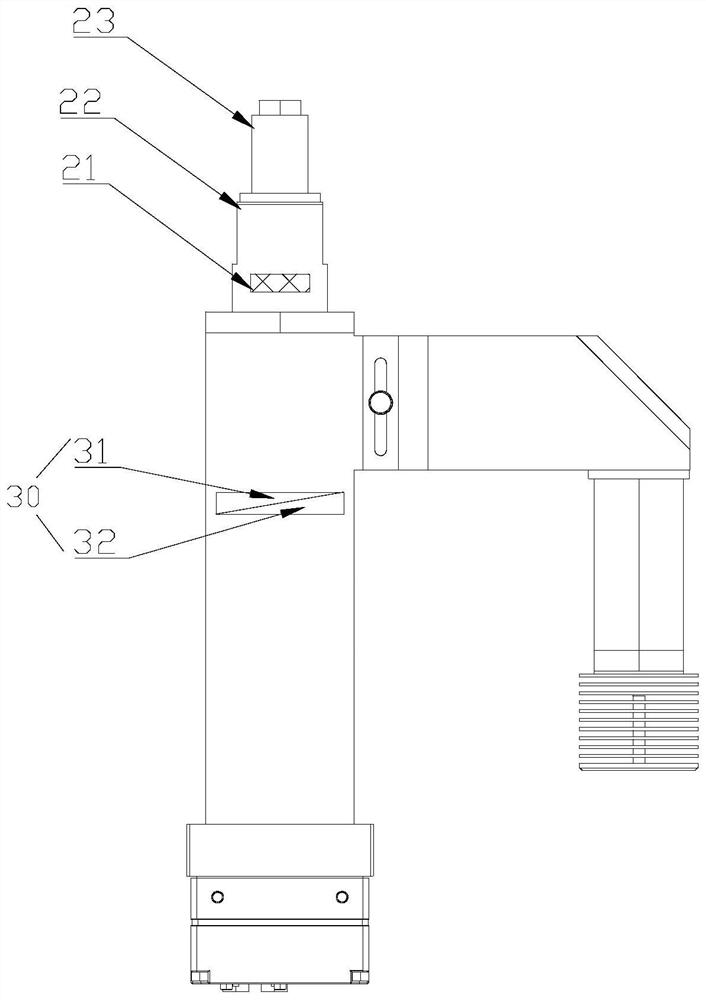

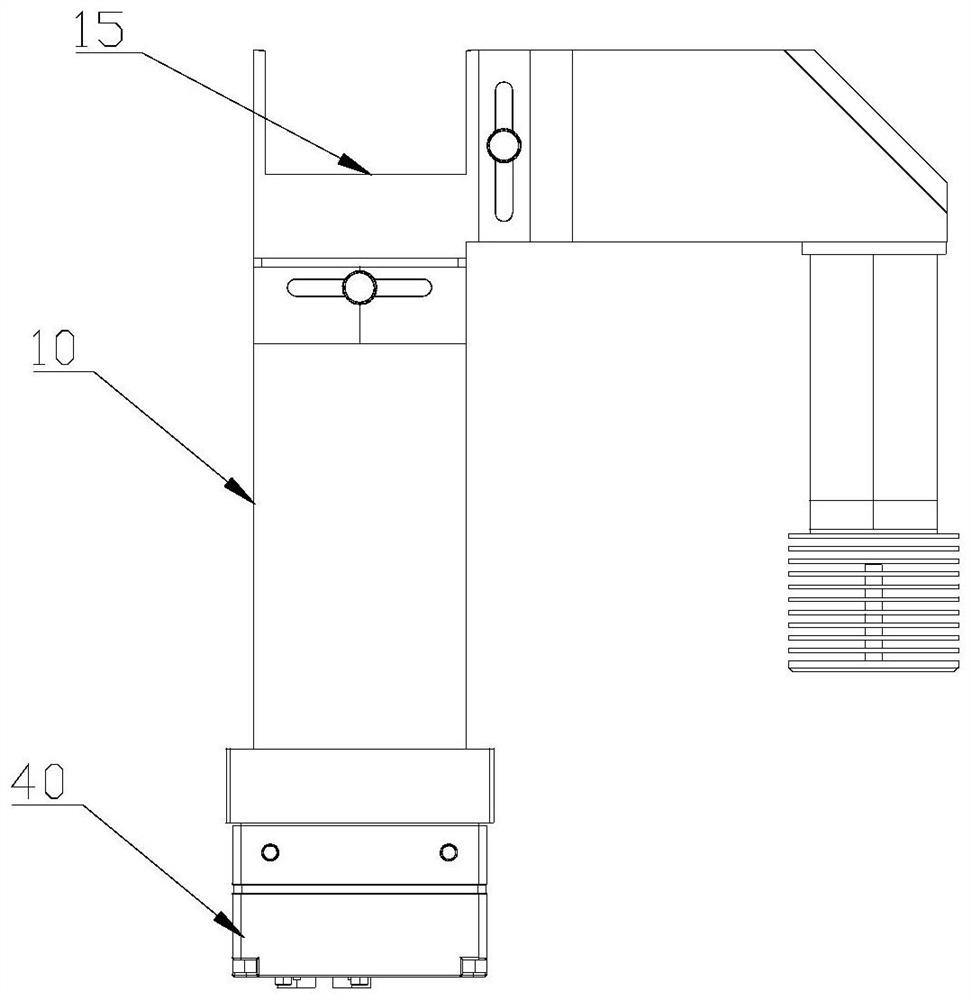

[0031] see Figure 1-Figure 5 , is an AOI indentation detection system proposed by an embodiment of the present invention, the AOI indentation detection system includes a housing 10, a spectroscopic adjustment button 11, a polarization adjustment button 12, a TDI camera 20, and a DIC prism 30; the DIC prism 30 includes a first prism 31 and a second prism 32; the TDI camera 20 and the DIC prism 30 are arranged at intervals in the housing 10; the spectroscopic adjustment button 11 is connected to the DIC prism 30 for adjusting The distance between the DIC prism 30 and the TDI camera 20; the polarization adjustment button 12 is connected to at least one of the first prism 31 and the second prism 32 for adjusting the first The distance between the prism 31 and the second prism 32.

[0032] In the above scheme, there is a slight distance between the first prism 31 and the second prism 32 of the DIC prism 30, and when the distance between the first prism 31 and the second prism 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com