Device and method for testing birefringence of optical material

An optical material and testing device technology, which is applied in the direction of using optical devices, measuring devices, and material analysis by optical means, can solve the problems of insufficient birefringence frequency dispersion characteristics and lack of birefringence temperature dispersion evaluation, etc. Achieve the effect of improving test efficiency and shortening development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

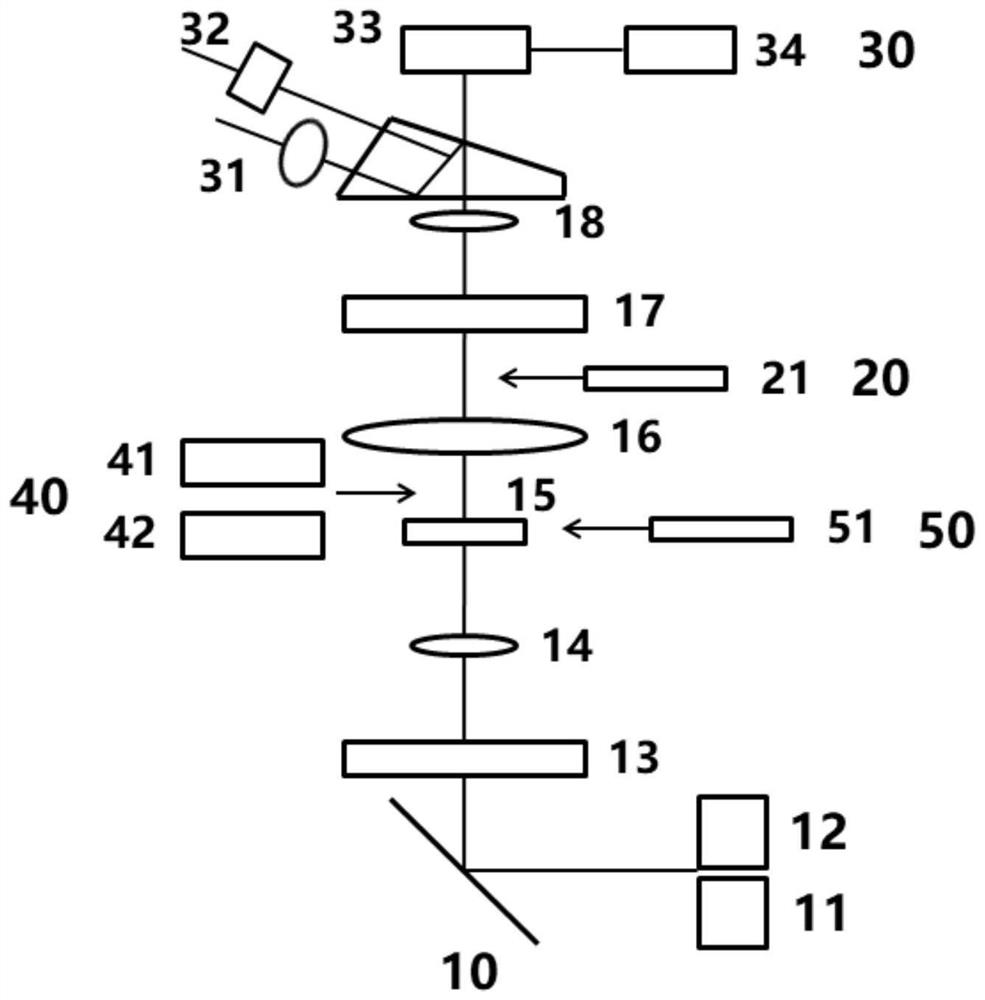

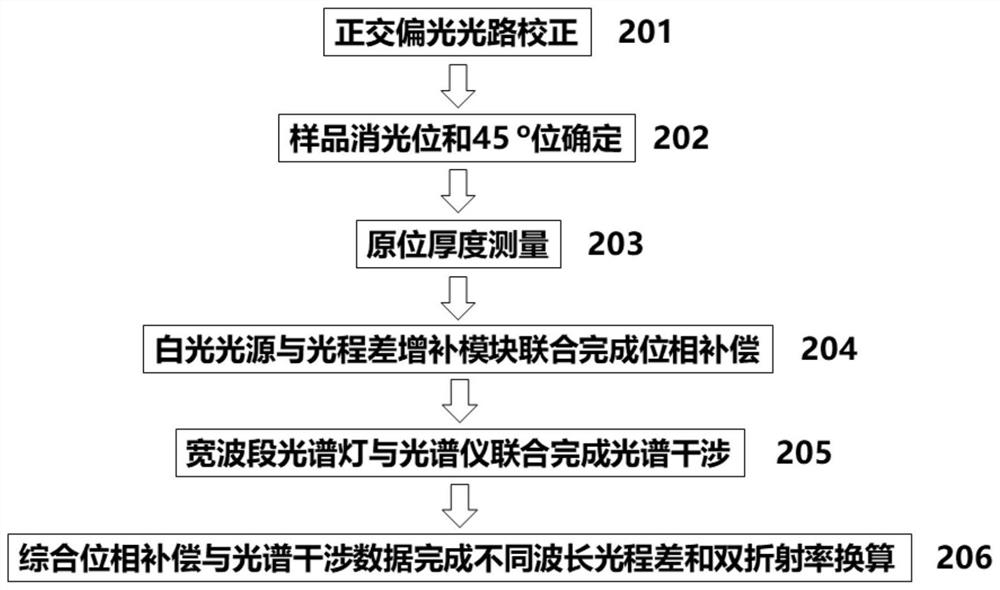

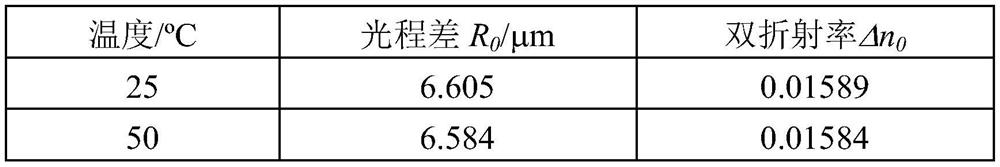

[0069] like figure 1 As shown, the optical material birefringence test device includes five systems: multi-wavelength optical path system 10, phase compensation system 20, phase detection and processing system 30, in-situ thickness measurement system 40 and temperature control system 50, as well as dual optical path modules and orthogonal Polarization module, optical path difference supplementary module 21, phase detection module and optical path difference calculation module, fast focus module 41, automatic lifting module 42, and temperature control module 51 are eight modules.

[0070] The multi-wavelength optical path system 10 includes a dual optical path module and an orthogonal polarization module;

[0071] The phase compensation system 20 includes an optical path difference supplementary module 21 to provide optical phase compensation;

[0072] The phase detection and processing system 30 includes a phase detection module and an optical path difference calculation modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com