Spherical wavefront curvature radius measuring device and measuring method

A technology of curvature radius and spherical wavefront, applied in the field of optical sensing measurement of precision instruments, can solve problems such as insufficient discussion, and achieve the effect of compensating for difficult alignment operations and efficient data dynamic collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

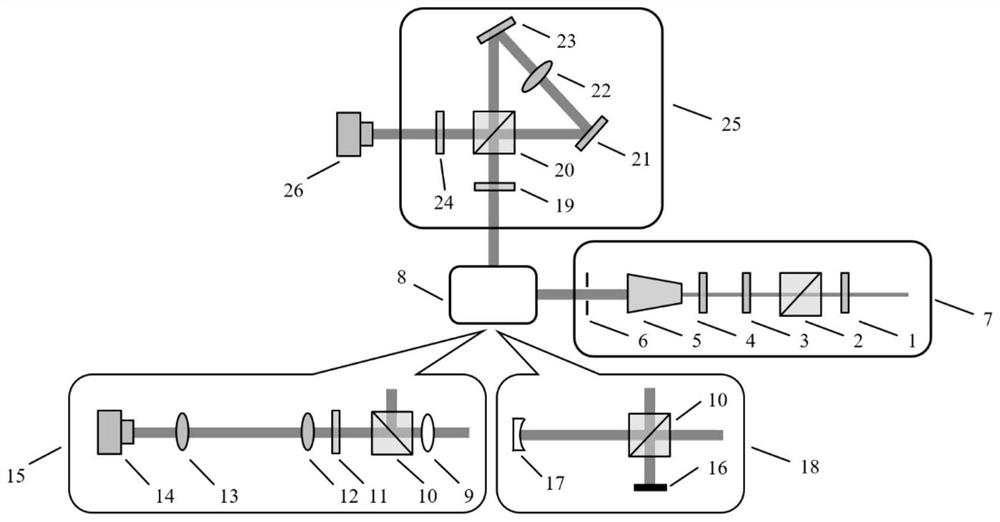

[0023] figure 1 It is a schematic diagram of the overall structure of the present invention; as figure 1As shown, a spherical wavefront radius of curvature measurement device of the present invention includes an initial wavefront adjustment module 7, a spherical wave generation module 8, and a radial shear interference module 25; the spherical wave generation module 8 includes a transmission A spherical wave generation module 15 and a reflective spherical wave generation module 18; output coupling beams from the laser, the coupling beams are used to generate the initial input wavefronts of two different types of spherical waves, and the initial wavefronts are adjusted by the initial wavefront adjustment module 7 They can enter the transmission type spherical wave generation module 15 and the reflection typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com