Underground passage supporting structure for underneath passing existing large-section shallow-buried pipe gallery and construction method

A technology for underground passages and supporting structures, which is applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve problems such as affecting the normal use of pipelines inside the pipe gallery, instability during excavation, and failure to meet the conditions for undercutting. , to achieve the effect of good promotion and application prospect, simple construction operation and good implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

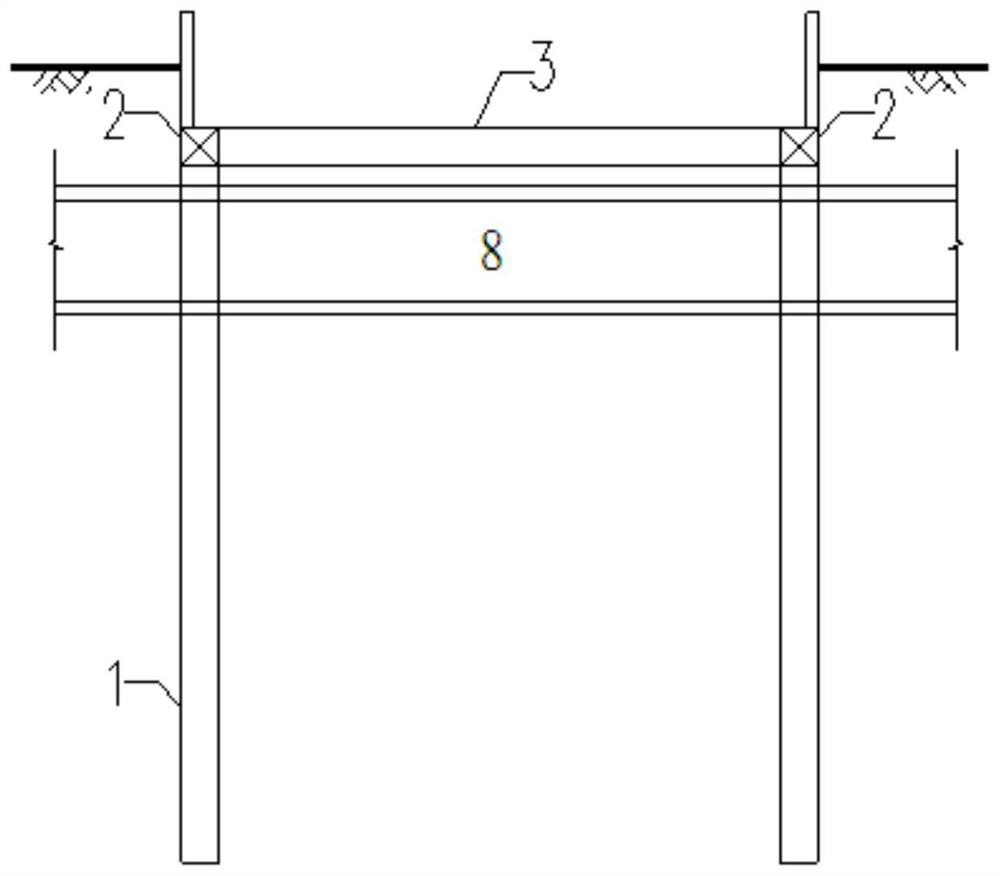

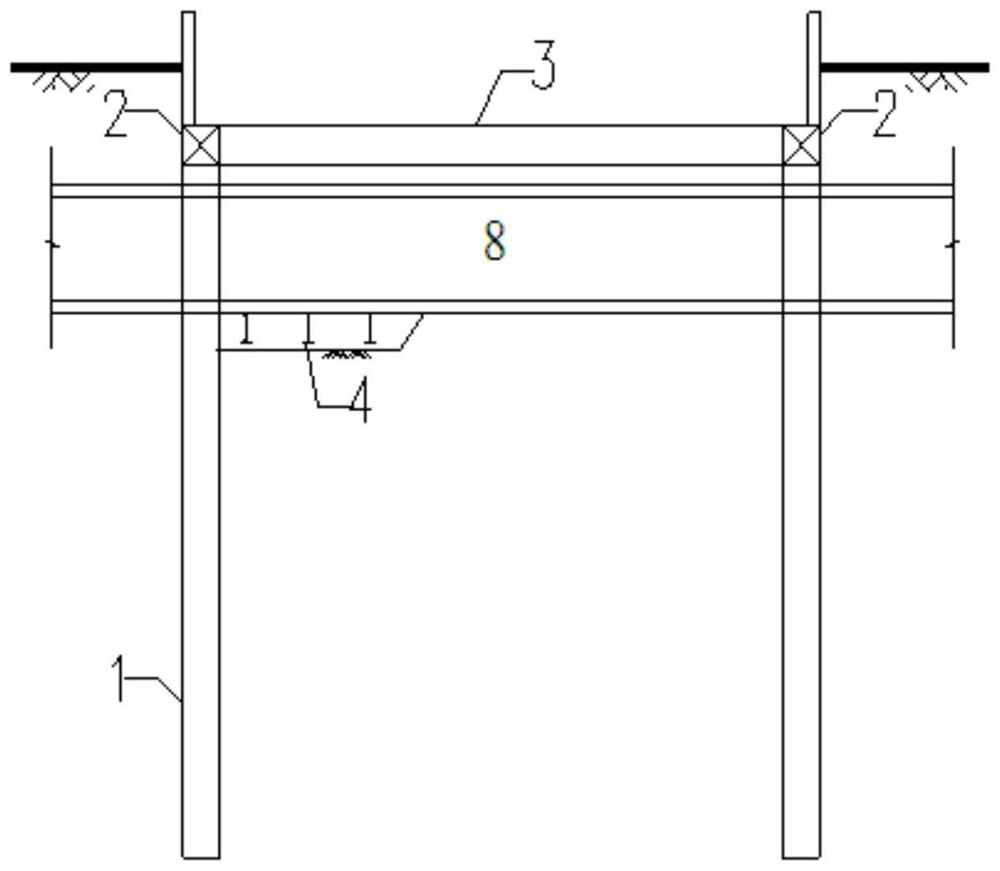

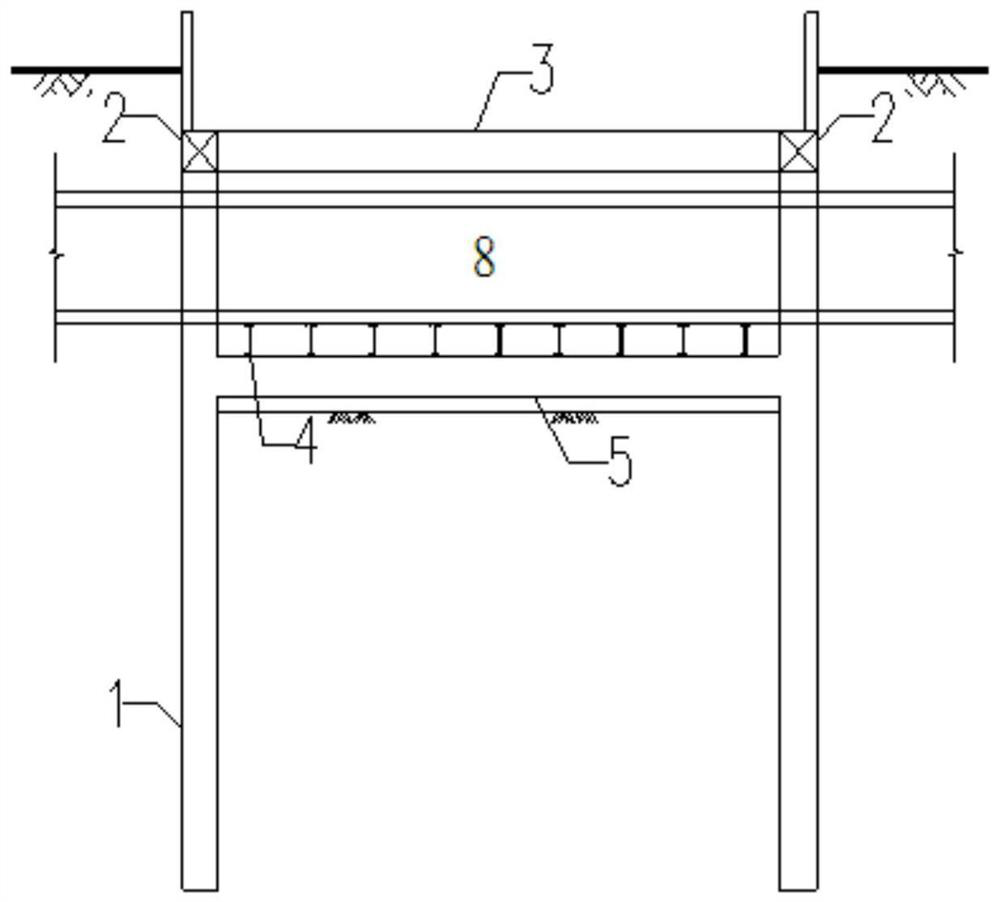

[0037] This embodiment provides an underground passage support structure that passes through the existing large-section shallow-buried pipe gallery, is suitable for the construction of underground passages that pass under the existing large-section shallow-buried pipe gallery, and has the functions of protecting the existing pipe gallery and providing underpass. The role of the channel construction work surface; the support structure of the underground channel under the existing large-section shallow buried pipe gallery in this embodiment is as follows Figure 6 to Figure 8 As shown, it includes bored cast-in-place pile 1, crown beam 2, horizontal concrete support 3, I-beam 4, and concrete support beam 5; bored cast-in-place pile 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com