Prism arranging machine with overturning function

A technology of film arranging machine and turning mechanism, which is applied to manufacturing tools, conveyor objects, conveyor control devices, etc., can solve the problems of difficulty in ensuring high-precision movement, affecting the accuracy of film arranging, and complex structure, and achieves fast action process, High precision of chip arrangement and the effect of meeting production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in more detail below with reference to the accompanying drawings and examples.

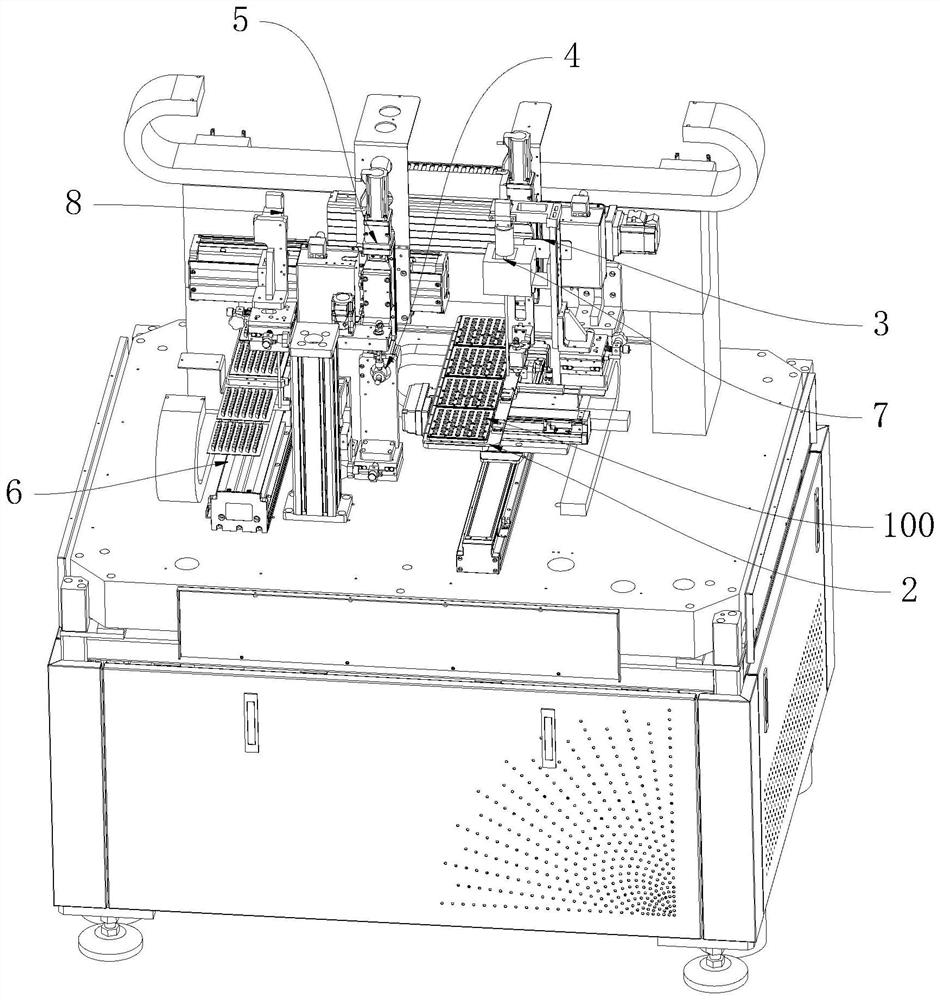

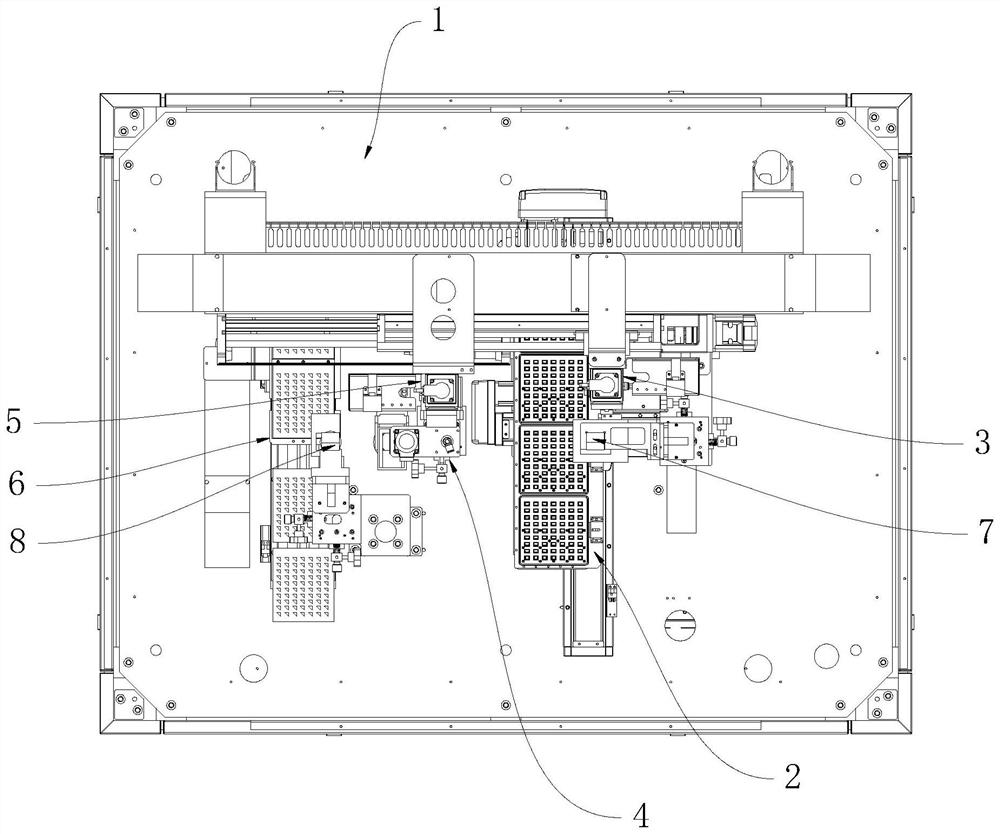

[0031] The present invention discloses a prism drain machine having a flip function, a combination Figures 1 to 11 As shown, it includes an organic table 1, and the machine is provided with an upper material flat transfer station 2, a prism pickup mechanism 3, a prism flip mechanism 4, a prism drain mechanism 5, and a workpiece assembly station 6, wherein:

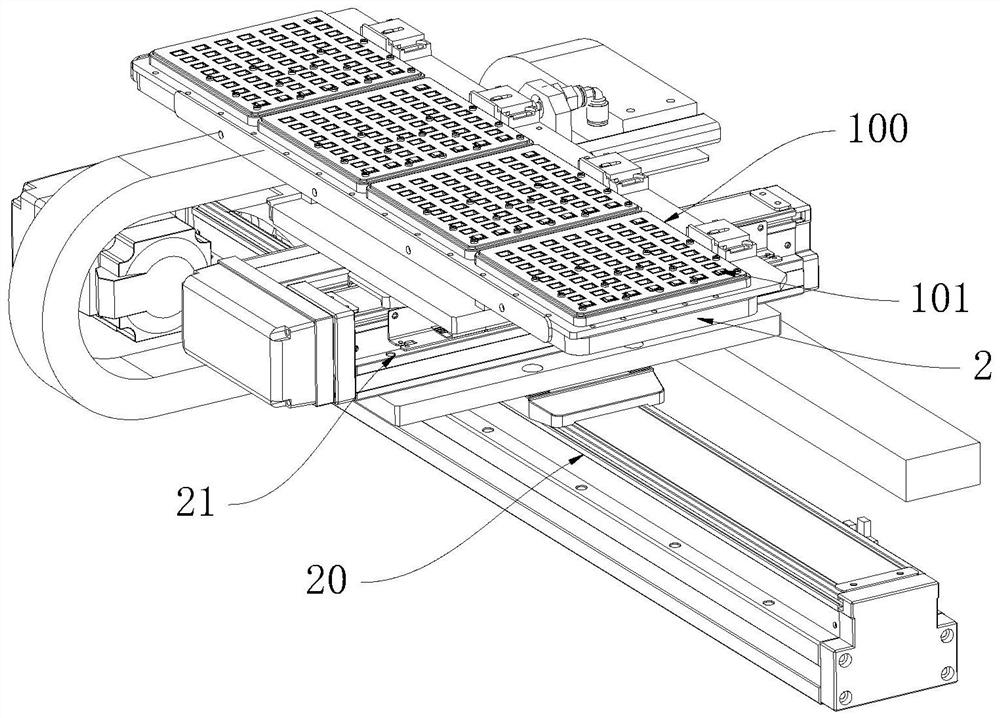

[0032] The upper material flat bearing table 2 is used to load the jealousy disk 100;

[0033] The prism pickup mechanism 3 is used to pick up the triangular prism 101 in the jade disk 100 and placed in the prism flip mechanism 4;

[0034] The prism flip mechanism 4 is for flipping the triangular prism 101 in a predetermined angle;

[0035] The prism drain mechanism 5 is configured to pick up the triangular prism 101 after the prism flip mechanism 4, and the triangular prism 101 is placed on the glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com