Automatic packing box boxing and capping production line

A technology for automatic cartoning and packaging, which is applied in the directions of packaging, transportation and packaging, individual objects, etc. It can solve the problems of low yield and the inability to guarantee the automatic closure of each lid of the packaging box, so as to avoid participation, improve hygienic quality and The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment, the specific embodiment of the present invention is described in further detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

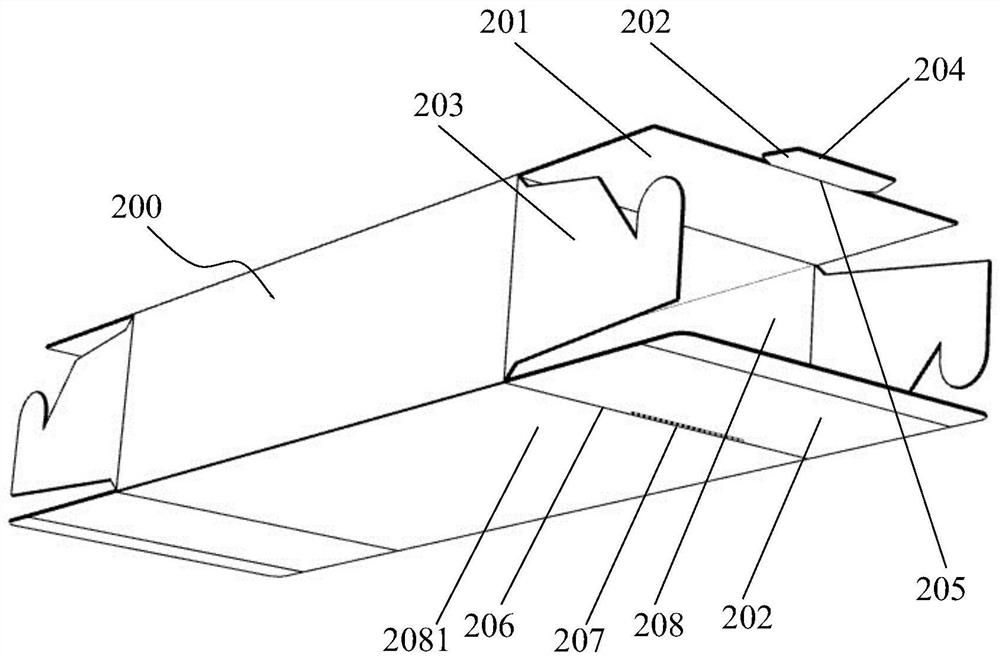

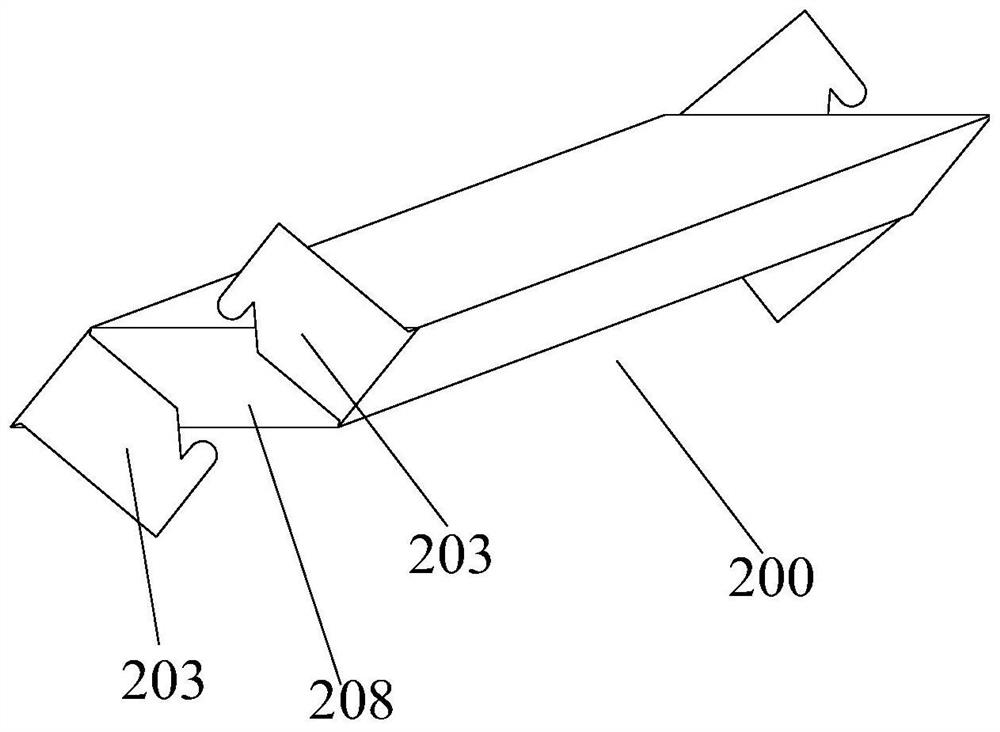

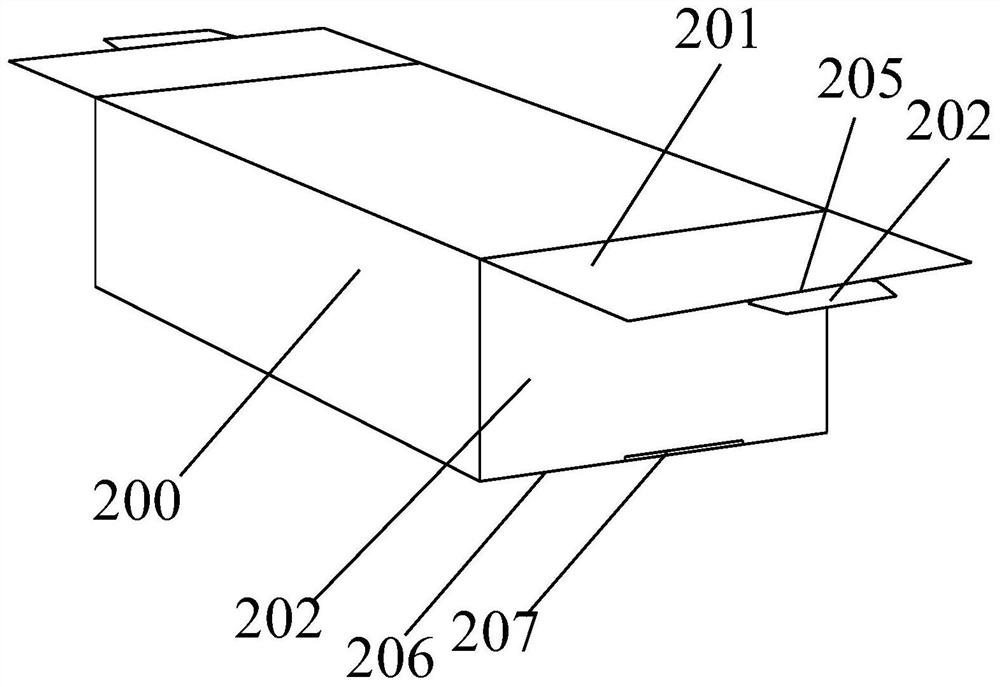

[0032] Such as Figure 1A As shown, in the specific embodiment of the present invention, the packaging box 200 is a paper packaging box, and the two openings 208 of the packaging box have an upper cover 201, a lower cover 202, and two opposite buckle covers 203 as an example, wherein Each buckle cover 203 has an intersection 2031 for mutual cross fastening; obviously, the packaging box 200 can only have the upper cover 201 or only two relative snap covers or only the lower cover 202 or any Combined styles of two types of covers, such as Figure 1BAs shown, do not go into details here, the production line of the present invention can be used for processing this similar any kind of packing box, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com