Pre-plasticized backpressure change-over valve block of injection molding machine

An injection molding machine and back pressure technology, which is applied in the field of injection molding machine pre-molded back pressure switching valve block, can solve the problems of reducing spring force, reducing the assembly space of switching valve block, reducing the volume of valve block, and high pressure regulation deviation. Spring force, avoiding the effect of non-integrated installation and avoiding biased pressure regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

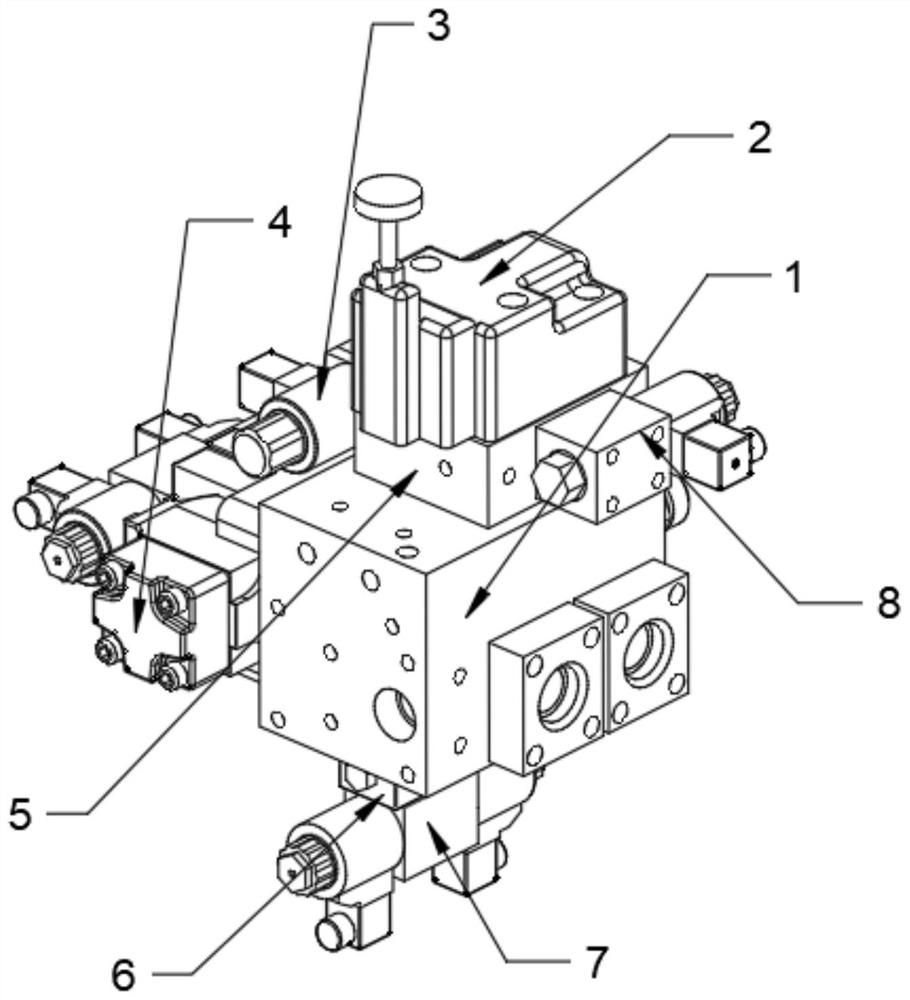

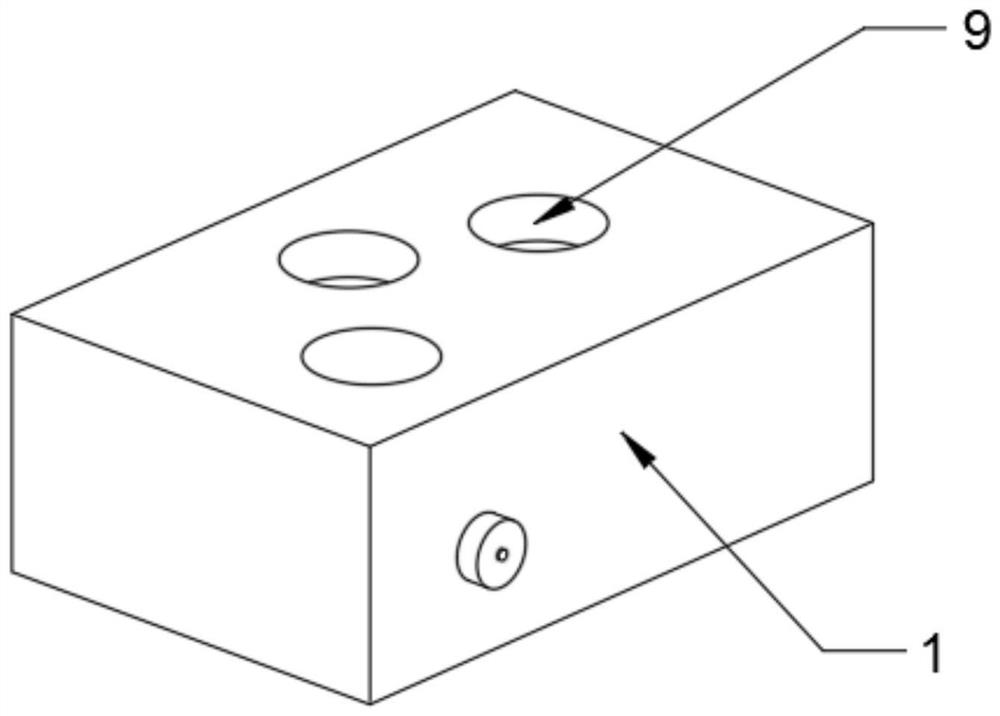

[0029] Embodiment one: refer to Figure 1-7 , a premolded back pressure switching valve block for an injection molding machine, comprising an injection valve block 1, a superimposed valve block 5 is provided on the top surface of the injection valve block 1, and a plug-in pilot relief valve 2 is provided on the top surface of the superimposed valve block 5 , the plug-in pilot relief valve 2 is equipped with a plug-in overflow structure B through opening a threaded hole pipe, and a plurality of valve holes 9 are opened on the surface of the injection valve block 1, and the inside of the valve holes 9 is equipped with a damping structure A , the plug-in overflow structure B includes a threaded housing 18 and a sealing sleeve 22, the bottom opening of the threaded housing 18 is fixedly connected with the top opening of the sealing sleeve 22, and the sealing sleeve 22 is inserted into the through hole on the surface of the stacked valve block 5, and the After screwing the adjustin...

Embodiment 2

[0030] Embodiment two: refer to Figure 1-7, on the basis of Embodiment 1, a pre-molded back pressure conversion valve block for an injection molding machine, one end of the adjusting bolt 20 located at the top of the threaded casing 18 is provided with an adjusting nut 19, and both sides of the limit piece 24 are provided with a circle The inside of the round hole is provided with a cylindrical spring, the top of the threaded housing 18 is provided with a through hole for the adjustment bolt 20 to pass through, and the bottom of the sealing sleeve 22 is provided with a through hole for the movable column 21 to pass through, and the sealing sleeve 22 There are overflow ports on both sides of the cover, and the overflowing liquid will enter through the bottom through hole of the sealing sleeve 22, and flow away at the overflow ports on both sides of the sealing sleeve 22, so as to realize the effect of the overflow valve. The threaded housing 18 The outer ring of the plug-in pi...

Embodiment 3

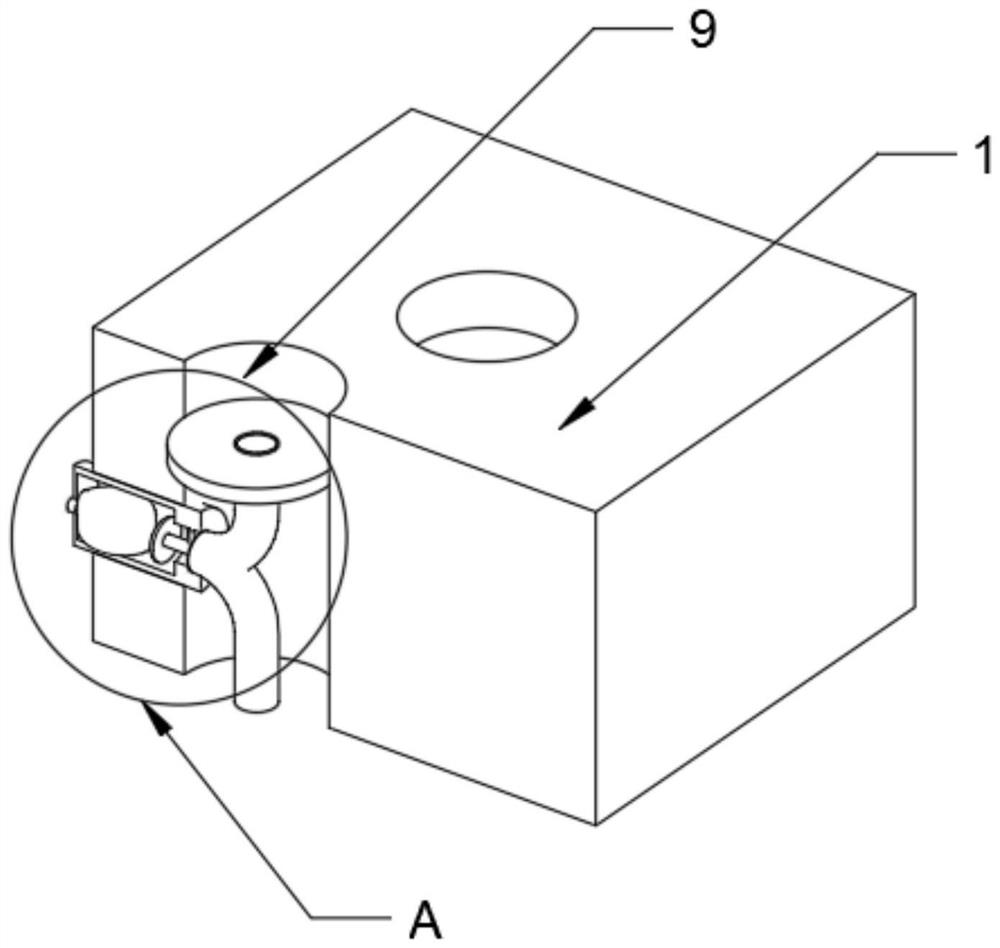

[0031] Embodiment three: refer to Figure 1-7 , on the basis of Embodiment 2, a premolded back pressure conversion valve block for an injection molding machine, the damping structure A includes a damper housing 17, the side walls of the valve holes 9 are provided with through holes, and the inner walls of the through holes and the damper The outer ring of the casing 17 is clamped, and the end of the damper casing 17 located inside the valve hole 9 is covered with a liquid inlet pipe 12 and a liquid outlet pipe 13, and the end of the liquid inlet pipe 12 far away from the damper casing 17 is covered with a liquid blocking plate 10. The outer ring of the liquid blocking plate 10 is welded to the inner wall of the valve hole 9, and the damper housing 17 is provided with an air bag inflation valve 16 at one end outside the injection valve block 1, and the other end of the air bag inflation valve 16 is provided with a valve located at the damper housing. 17 inside the air bag 15, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com