Injection mold positioning mechanism

A technology of positioning mechanism and injection mold, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc. It can solve the problems of affecting the heat dissipation of the lower mold, without assistance in heat dissipation, and without heat dissipation, so as to achieve flexible use and rapid improvement The effect of cooling molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

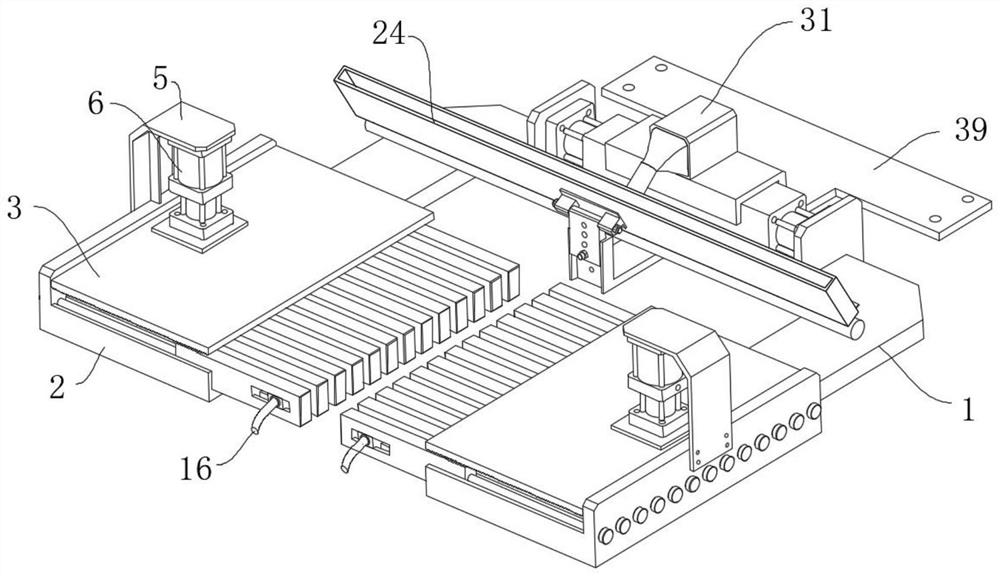

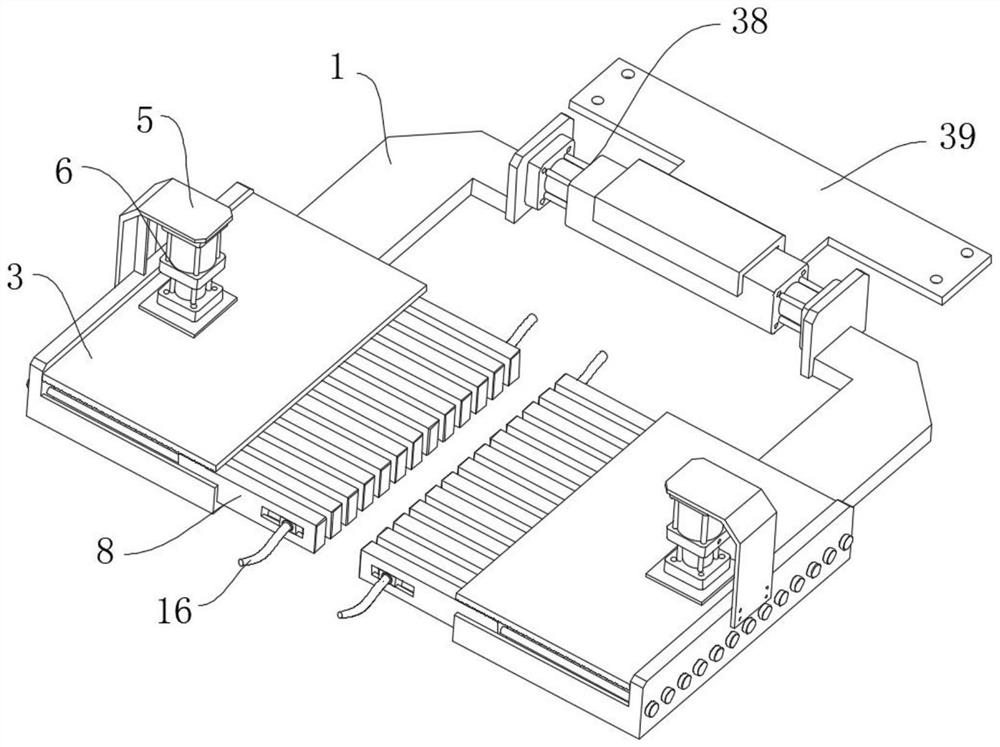

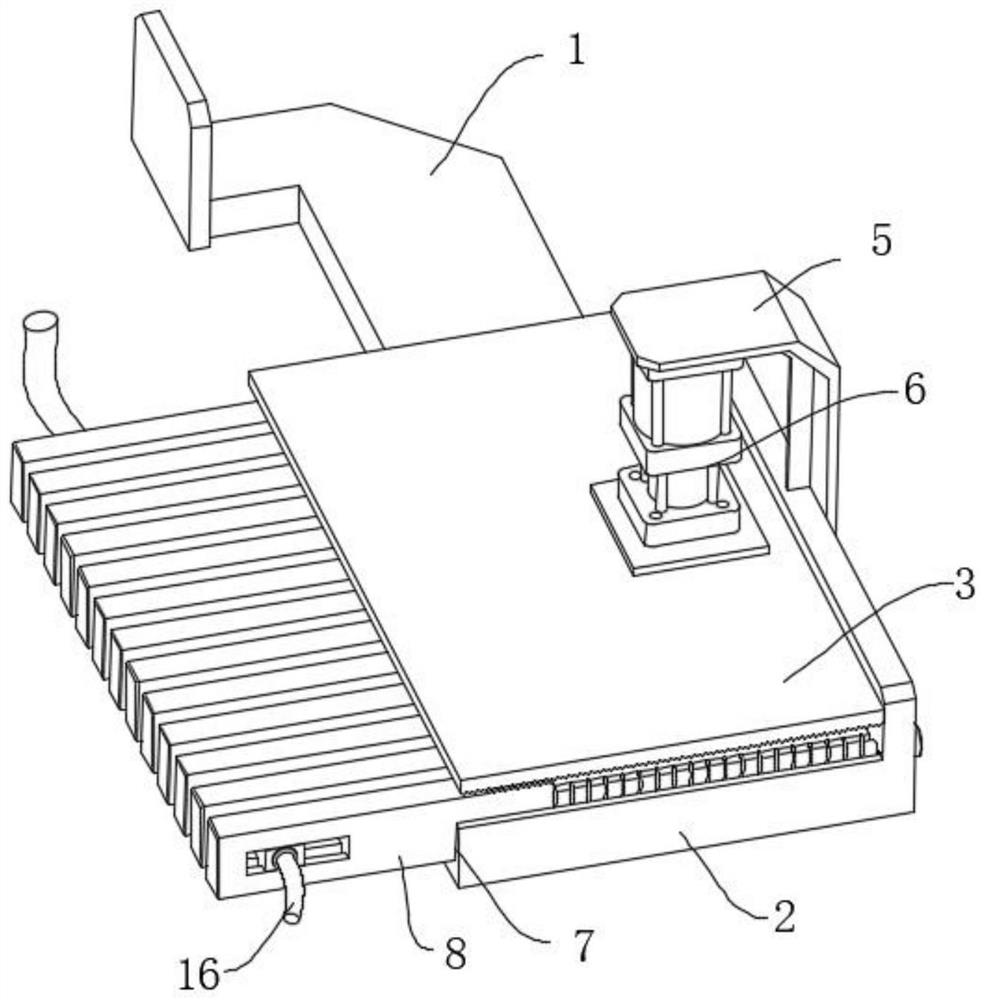

[0032] Such as Figure 1-Figure 10 The injection mold positioning mechanism shown includes a connecting plate 1. The number of connecting plates 1 is set to two and arranged symmetrically. The front end of the base plate 2 is fixedly connected with a base plate 2, and the upper end surface of the base plate 2 is slidably installed with several limit blocks 8 along both sides. An elastic mechanism is arranged between one end of the limit block 8 and the edge of the base plate 2. Pressing plate 3 is installed by lifting mechanism, and lifting mechanism controls pressing plate 3 to move down and press on the surface of limiting block 8 to stabilize limiting block 8, and the front of telescopic mechanism is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com