Foam die cutting piece manufacturing method capable of preventing handle film from adhering to material belt

A production method and technology of die-cut parts, which are applied in metal processing and other directions, can solve the problems of large size, easy sticking of the handle position on the tape film, and inability to peel it off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

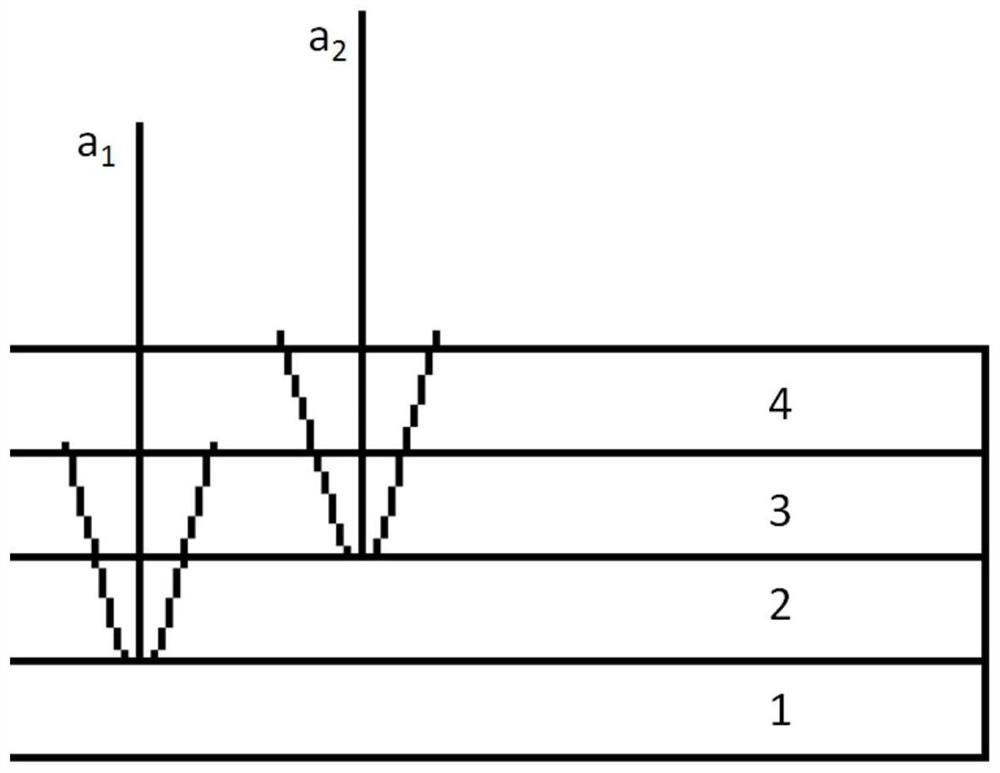

[0043] A foam die-cut that prevents the handle film from sticking to the strip, such as Figure 11 , the die-cut piece includes a handle film 5 , foam 4 , double-sided adhesive tape 3 and tape film 8 in sequence. The handle film 5 is pasted with an anti-adhesive protective film 71 that prevents the handle film 5 from sticking to the tape film 8 .

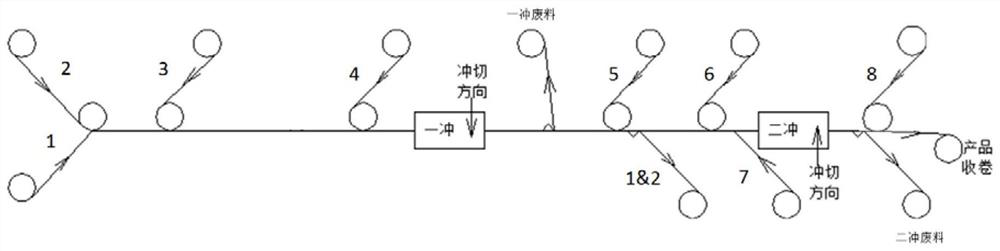

[0044] The method for making a foam die-cut piece that prevents the handle film from sticking to the material tape, such as figure 1 , the method includes the following steps:

[0045] (1) Bonding of the primary material tape: the first auxiliary release film 2, the double-sided adhesive tape 3 and the foam 4 are sequentially pasted on the first protective film 1 to form a primary material tape;

[0046] (2) First-cut die-cutting and waste discharge: perform one-cut die-cutting on the first-grade material strip in the first-cut die-cutting machine, and discharge one-cut waste;

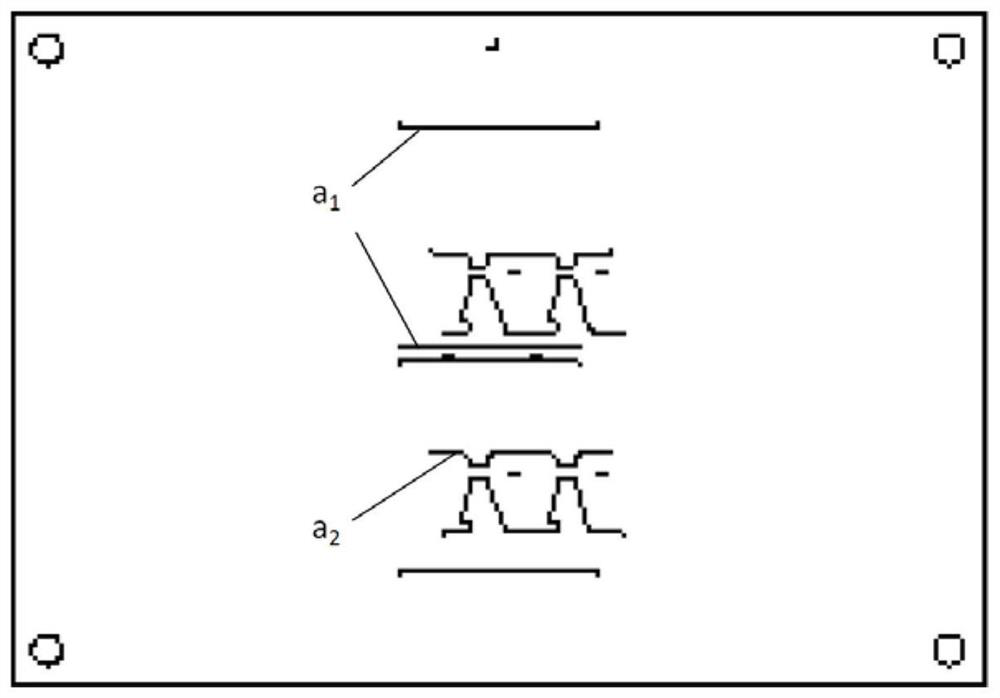

[0047] like Figure 2-3 , the one-punch die-cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com