Mechanical manufacturing stamping device

A punching device and machine manufacturing technology, applied in the field of mechanical punching, can solve the problems of inconvenient pressure application, poor punching effect, accidental injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

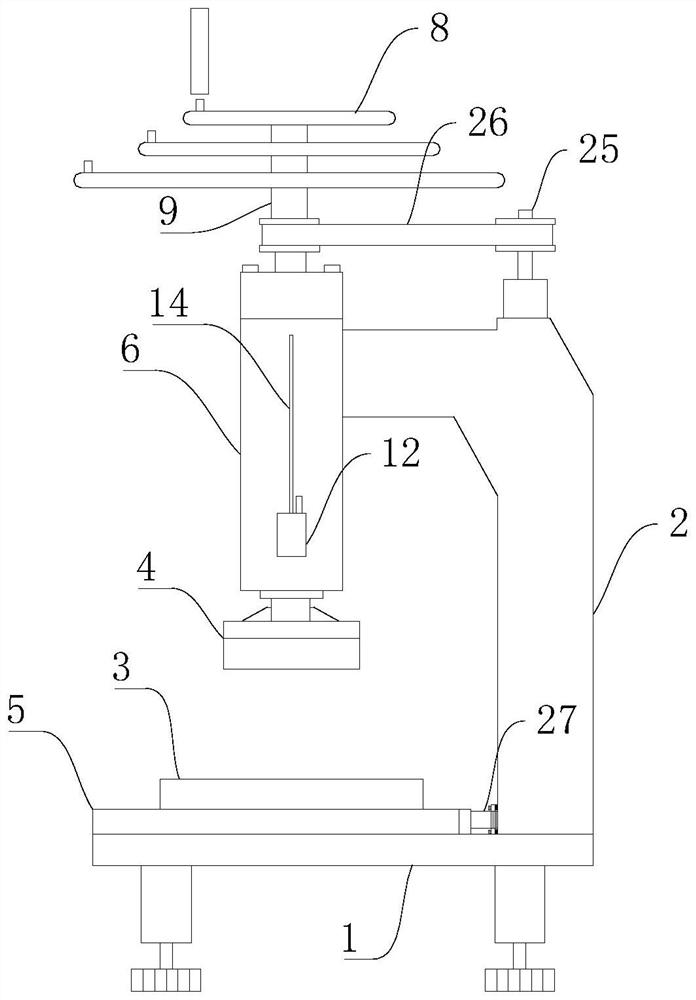

[0049] Please refer to Figure 1-Figure 8 , figure 1 Shown is a schematic structural view of one of the stamping components in the embodiment of the present invention;

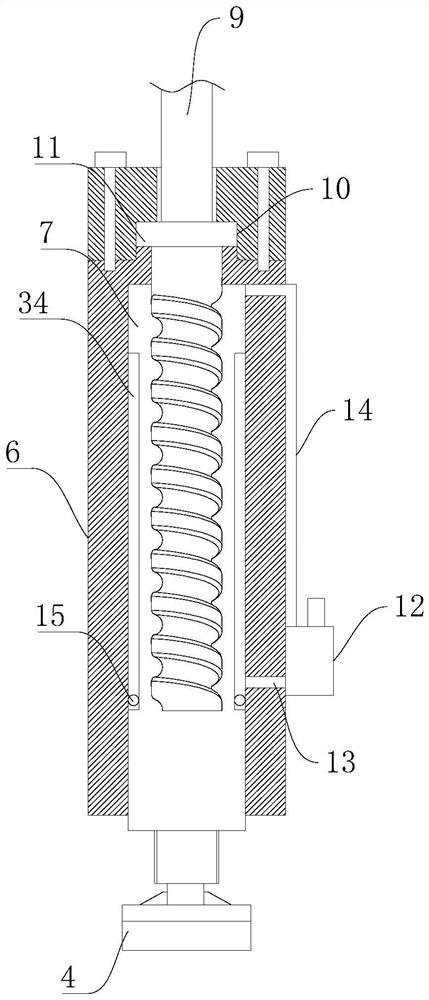

[0050] figure 2 Shown is a schematic diagram of the connection of the installation sleeve 6, the connecting shaft 9 and the stamping rod 7 in the embodiment of the present invention;

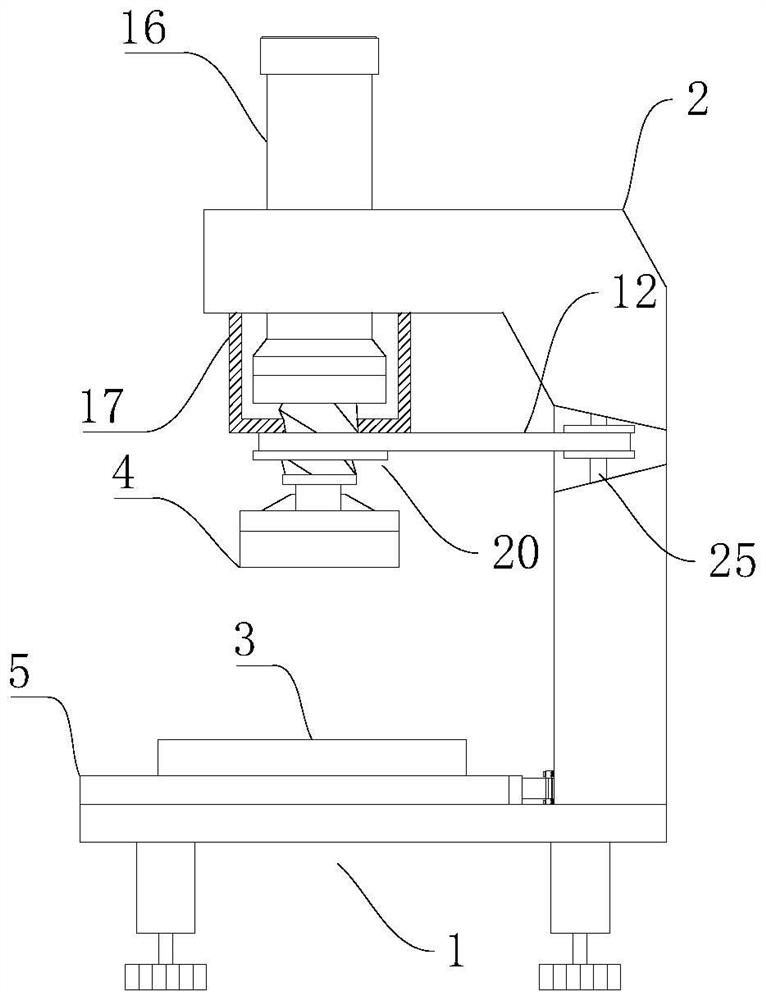

[0051] image 3 Shown is a schematic structural view of another stamping assembly in the embodiment of the present invention;

[0052] Figure 4 Shown is a schematic structural view of the output end of the hydraulic push rod 16 in the embodiment of the present invention;

[0053] Figure 5 Shown is a schematic structural diagram of the through hole 19 in the embodiment of the present invention;

[0054] Image 6 Shown is a schematic diagram of the installation of the linkage assembly in the embodiment of the present invention;

[0055] Figure 7 shown as Image 6 The enlarged schematic diagram of A in the middle;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com