Thermal insulation, temperature control and moisture-proof system for cable trench of highway tunnel

A technology for thermal insulation and highway tunnels. It is used in cable installation in tunnels, control/regulation systems, and cable installation in underground pipelines. problems, to achieve the effect of isolating or reducing heat transfer, ensuring service cycle, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

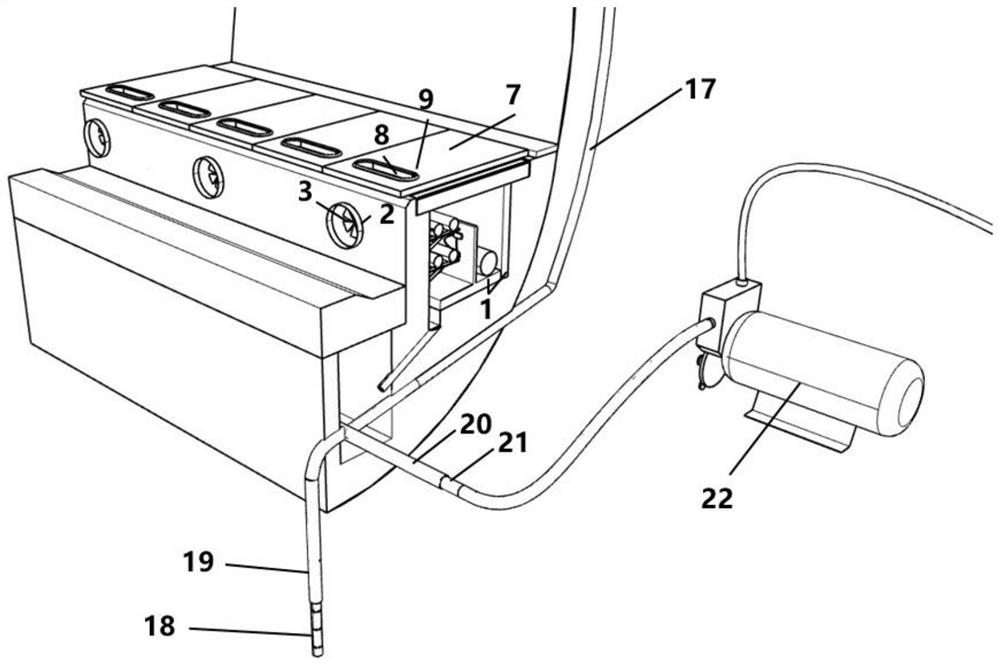

[0033] This embodiment is applied to high ground temperature road tunnels. see Figure 1~4 , a highway tunnel cable trench heat insulation, temperature control and moisture-proof system, including a cable trench heat insulation module, a cable trench cooling and moisture-proof module, a cable trench drainage module, a cable trench waterproof wall module and a groundwater pumping and drainage module, in the cable trench The inner wall of the cable trench is equipped with a thermal insulation module, and the waterproof wall module and the drainage module are respectively installed inside the cable trench. The groundwater pumping and drainage modules are installed on the and inverted arches.

[0034] see figure 1 and figure 2 , the heat insulation module of the cable trench is a heat insulation board 1, and the heat insulation board 1 is arranged close to the inner wall of the cable trench. In this embodiment, the heat insulation board 1 is a self-adhesive rigid polyurethane ...

Embodiment 2

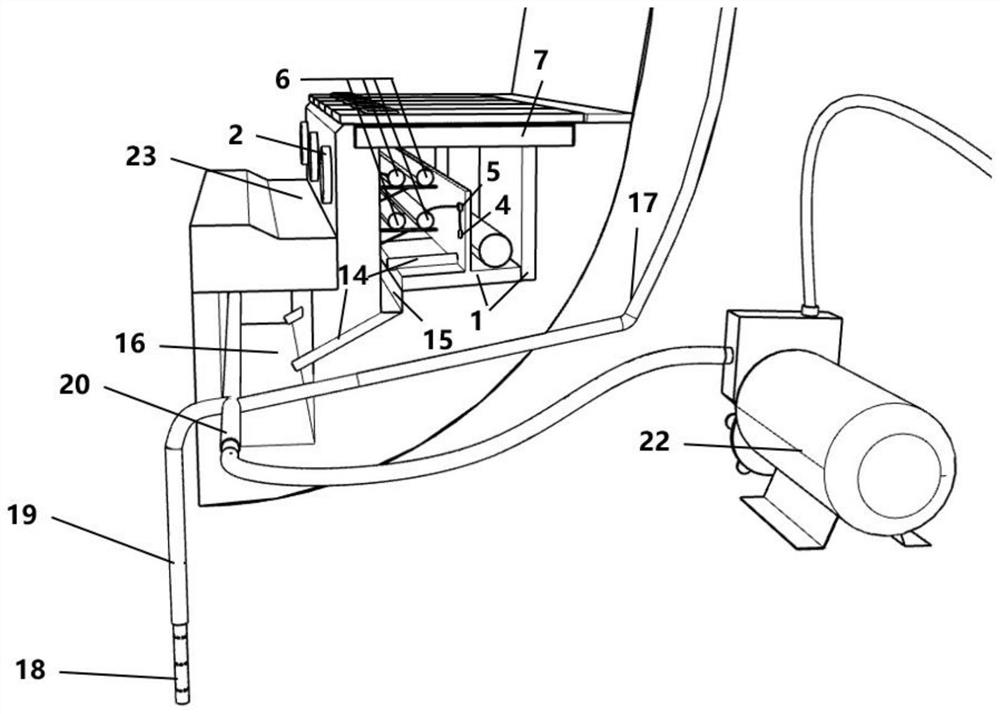

[0040] This embodiment is applied to road tunnels in cold regions, see Figure 5 and Figure 6 , the present embodiment is slightly adjusted based on the structure of embodiment 1. The difference is that heat insulation boards 1 are arranged around the inner wall of the cable trench, the distance between the exhaust fan and the ventilation groove is increased, and the leaking drain pipe 17 is wound outside the leakage drain pipe 17. The heating cable 24 is also equipped with an electric heating device 25, and the electric heating device 25 is connected with the temperature and humidity sensor 4, and the cable 6 is used for direct power supply.

[0041] Heat insulation boards 1 are arranged around the inner wall of the cable trench to form a heat-insulating and airtight space. Avoid the temperature inside the cable trench being affected by the cold air and surrounding rock in the cave, which will cause the outer protective layer of the cable to become hard and brittle, which w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com