High-safety electric operation drawer unit

A drawer unit, safe technology, applied in the field of high-safety electric drawer unit, can solve the problems of increasing two costs, not complying with maintenance test regulations, wasting costs, etc., achieve simple circuit and mechanical structure, and ensure reliable operation of equipment , to avoid the effect of load operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

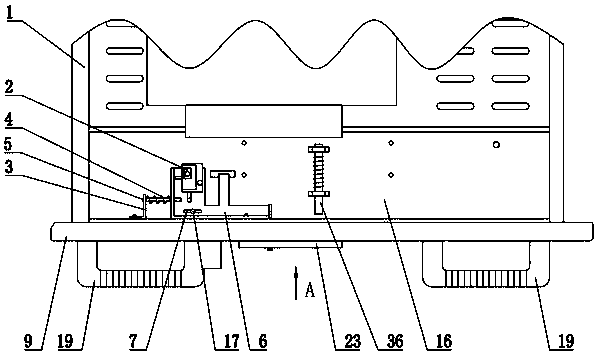

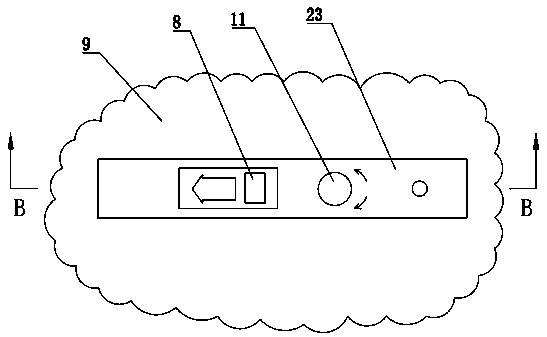

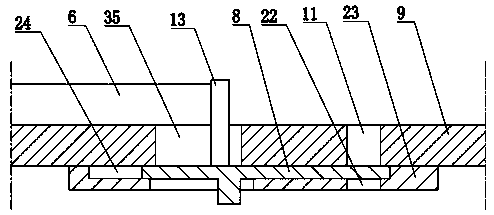

[0031] Please refer to the attached figure 1 , a high-safety electric drawer unit of the present invention, comprising a drawer-type switch cabinet, the drawer 1 has a bottom plate 10 and a front panel 9 located on the front side of the bottom plate 10 and exposing a drawer hole, the drawer 1 is rotatably mounted with a front and rear extension lead screw 36, the drawer hole is provided with a guide seat 25 that is engaged with the lead screw 36, and the front panel 9 is provided with a rocker socket 11 that penetrates front and back and corresponds to the lead screw 36, and is installed in the front panel 9. Insert and pull out the rocking handle 18 of the rocking handle jack 11, the rocking handle 18 and the leading screw 36 are provided with a torque transmission mechanism for making the two rotate synchronously, and the front side of the front panel 9 is slidingly installed with a cover, a The limit baffle 8 that exposes the rocker socket 11, the rear side of the front pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com